Plastic and Rubber Injection Molding Manufacturers

From prototyping to mass production — trusted by 5000+ global clients.

Comprehensive Molding Service & Solutions

How to Work with Us?

Upload a CAD File

Quote & Design Analysis

Manufacturing Begins

Parts Shipped

On-Time

Design and Engineering Support

- Material Selection Support

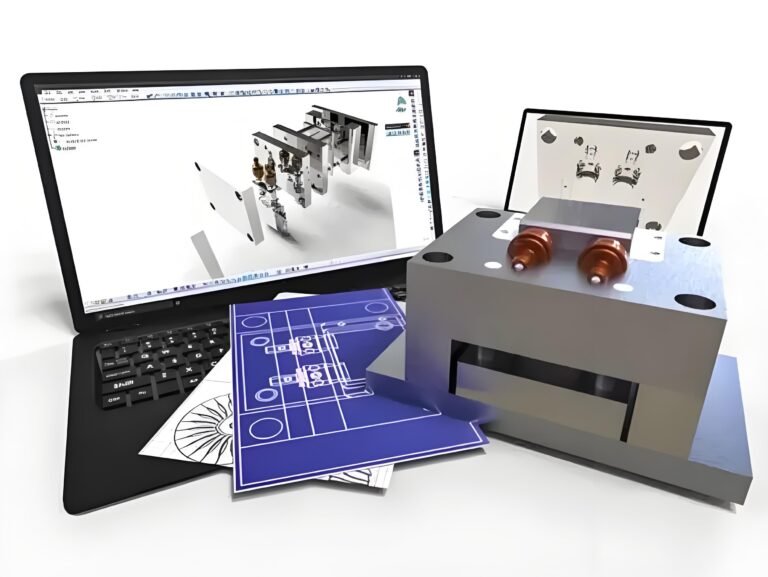

- Custom Mold Design

- Process Optimization

- Prototype Development

- Manufacturing Technical Support

- Quality Control & Testing

For inquiries, please email us at sales@swcpu.com . We’ll get back to you within 12 hours.

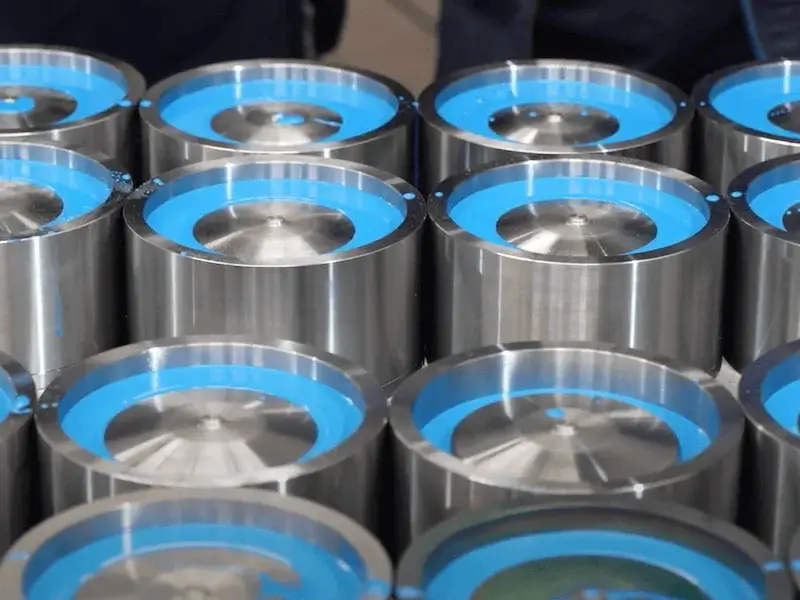

Strong Capacity

- Precision Manufacturing at Scale: Delivering millions of high-accuracy parts with a 99% defect-free rate.

- Versatile Production Capabilities: Custom molding for 15+ industries, manufacturing 50,000+ parts monthly.

- Efficiency & Reliability: With decades of experience, we proactively address challenges, ensuring seamless production, minimal errors, and on-time delivery.

- Cutting-Edge Facilities: Equipped with advanced machinery and large-scale capacity to meet complex manufacturing demands.

Drawing on years of experience as a china injection molding manufacturer, we proactively identify potential production issues and provide reliable, efficient solutions that minimize errors and delays.

Professional China Injection Molding Service Manufacturer

About Jiangzhi Injection Molding Manufacturer

Shaping the Future of Molding Solutions

Founded in 1978 as a family business, Jiangzhi started with a focus on local markets and cable manufacturing. Over the years, we expanded into customized rubber and plastic component production, and by 2008, we entered the global market with a commitment to delivering high-quality solutions. Today, Jiangzhi has grown into a 30,000-square-meter automated factory, equipped with state-of-the-art machinery to support a wide range of manufacturing needs.

Full-process Service Capabilities

Trusted by Industry Leaders

--Procurement Coordinator

Working with various suppliers for injection molding, CNC, and casting always led to communication breakdowns and production delays. After switching to Jiangzhi, we’ve seen a dramatic improvement. As trusted injection molding manufacturers, you’ve made our production process much smoother and more efficient.

--CPO

Our business depends on precision and quality, and finding injection molding manufacturers who can also handle other processes like CNC and casting was always a challenge. Your team’s ability to manage it all has improved our timelines and overall product quality. We now rely on you as our go-to manufacturing partner.

Injection Molding Manufacturers Support & Resources

Simply upload your CAD files, and we’ll provide an instant quote within 24 hours. Our fast response time helps you make decisions quickly and confidently.

We offer flexible options with no minimum order requirement for prototypes or small runs. Whether you need a few parts or larger production volumes, we tailor our services to meet your needs.

Absolutely! We specialize in fast turnaround and can adjust production schedules to meet urgent deadlines. Let us know your timeline, and we’ll make sure you get your parts on time, without compromising quality.

We use state-of-the-art inspection equipment and follow strict quality control processes at every stage of production. Plus, we provide sample approval before mass production, so you can confirm everything is to your satisfaction.

We’re here to help! If you need design adjustments, our design team will work with you to implement revisions quickly and seamlessly. Our goal is to ensure the final product meets your exact requirements.

Once you’ve received your quote and confirmed your design, simply confirm the order online. For payment, we accept a variety of secure options, and our team will guide you through the entire process for a smooth experience.

Yes! We offer a quality guarantee on all our parts. If there’s any issue with your order, we will rework or replace the parts as necessary to ensure your satisfaction.