Plastic and Rubber Injection Molding Manufacturers

As an injection molding company, Jiangzhi excels in high-quality prototyping, rapid tooling, and volume manufacturing to accelerate your custom plastic parts development. Our expert team uses advanced technologies to bring your ideas to life. Let’s build injection molding solutions for your business.

Contract Manufacturing Service

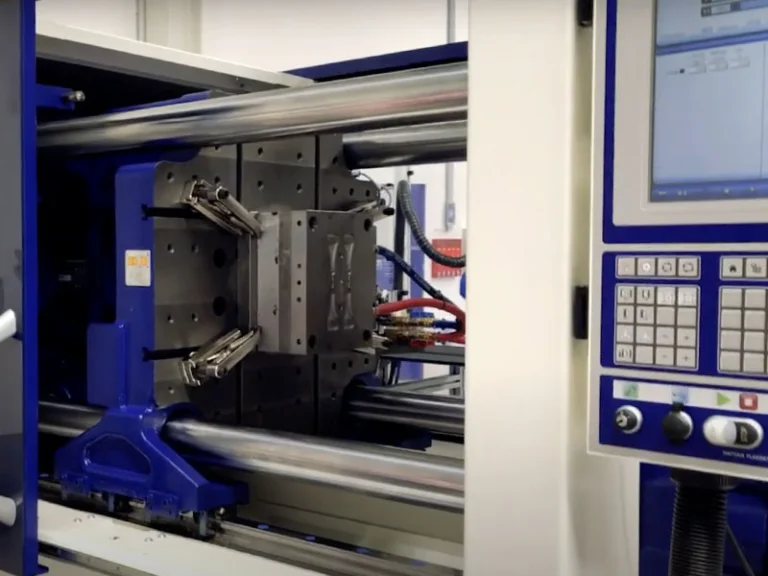

Injection Molding Service

Elevate your projects with our custom injection molding service. We excel in creating high-quality custom components, offering a diverse material selection, making intricate injection molding designs, and accommodating different sizes. Additionally, we specialize in overmolding and insert molding, providing versatile solutions for enhanced product functionality and durability.

Compression Molding Service

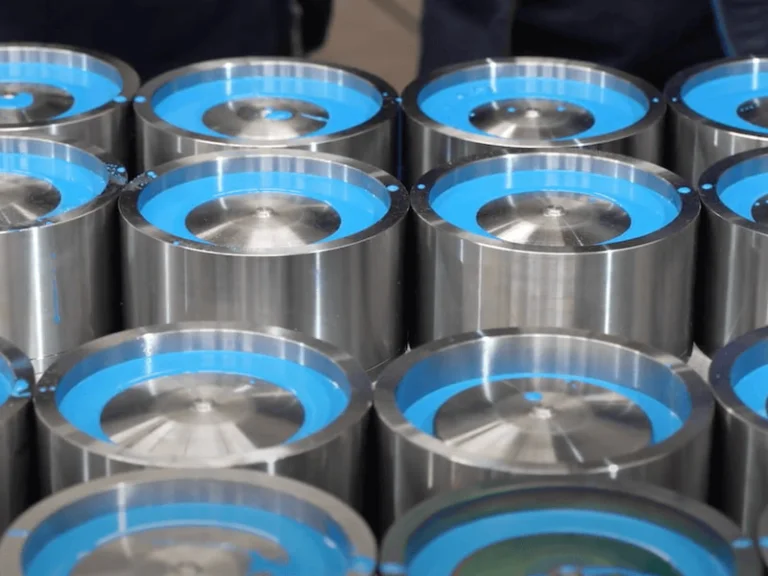

CNC Machining Service

Benefit from our short turnaround time for machined parts, combined with a variety of surface finishing options. Jiangzhi CNC services include: CNC Turning and CNC Milling. Our strong capacity ensures cost-efficient, high-volume production with tight tolerances down to ±0.05mm.

Cast Molding Service

From product development models and prototypes to low-volume production runs, Jiangzhi custom cast molding process is capable of producing parts that are highly similar in color, texture, feel and physical properties.

How to Work with Us?

Upload a CAD File

Quote & Design Analysis

Manufacturing Begins

Parts Shipped

On-Time

Design and Engineering Support

- Material Selection Support

- Custom Mold Design

- Process Optimization

- Prototype Development

- Manufacturing Technical Support

- Quality Control & Testing

We offer an online manual service, or you can send us an e-mail to sales@swcpu.com and we will contact you within 24 hours.

Strong Capacity

- Expert R&D Team: Delivering precision solutions with millions of parts and 99% defect-free quality.

- Fast Response: Providing quotes in 12 hours and 24/7 availability to keep projects on track.

- Diverse Manufacturing Solutions: Custom molding for 15+ industries, producing over 50,000 parts monthl

Our experience enables us to anticipate challenges and provide reliable, efficient solutions, minimizing errors and delays.

Custom Contract Manufacturing Capability

Professional Injection Molding One-Stop Service Company

Jiangzhi Other Processing Services

Injection Molding Manufacturers Support & Resources

Need Perfect Parts? Discover How Precision Plastic Molding Delivers Unmatched Quality and Accuracy? Maximize Efficiency and Minimize Waste.

What is injection molding service?

Injection molding is a manufacturing process used to produce parts by injecting molten material into a mold under pressure. The material solidifies to form a part.

Keywords: injection molding process, injection molding definition, plastic injection molding, molding machine, molding cycle

What are the benefits of injection molding services?

Custom injection molding service offers high precision, quick production cycles, and the ability to produce complex shapes in large quantities with minimal waste.

Keywords: high efficiency, mass production, precision molding, cost-effective manufacturing, molding advantages

What materials can be used in injection molding?

Custom Injection molding typically uses thermoplastics, thermosets, elastomers, and composites, with thermoplastic polymers being the most common.

What is the typical injection molding cycle time?

The cycle time can range from 10 to 30 seconds for small parts, but it depends on the material, mold complexity, and part size.

Keywords: injection molding cycle, cycle time, production speed, fast molding, molding time efficiency

What are common defects in injection molding and how can they be avoided?

Common defects include warping, sink marks, air traps, flash, and short shots. Proper mold design, temperature control, and material selection can help prevent these issues.

Keywords: injection molding defects, warping, sink marks, air traps, flash, mold design, defect prevention

How long does an injection mold last?

The lifespan of an injection mold depends on factors like material hardness, production volume, and maintenance. Typically, it can last anywhere from 100,000 to 1 million cycles.

Keywords: mold lifespan, mold durability, injection mold maintenance, mold wear, mold cycle count

How do injection molding costs down?

Injection molding costs are typically broken down into material costs, mold costs, labor, and machine operation costs. Mold costs are often the most significant upfront expense.

Keywords: molding costs, cost breakdown, injection molding pricing, mold expenses, cost-effective molding

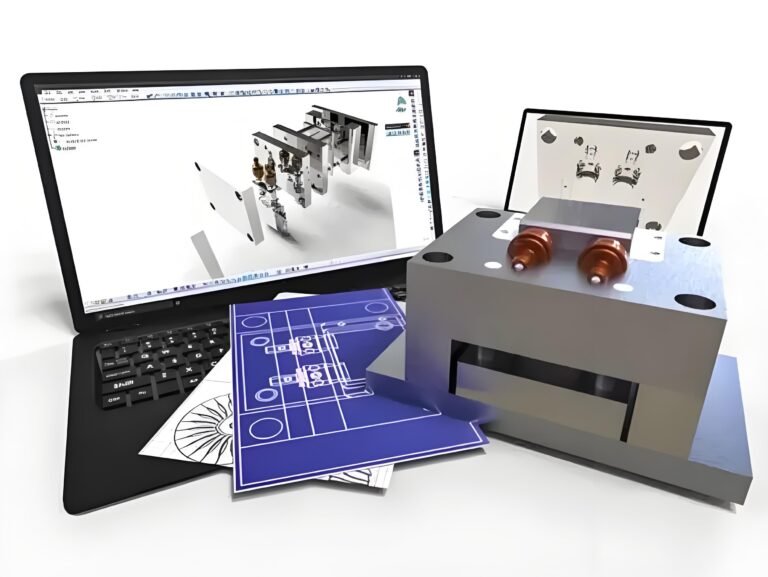

What is the importance of mold design in injection molding?

Proper mold design is crucial to ensure that the mold can withstand the pressures of injection molding, provide consistent part quality, and avoid defects.

Keywords: mold design, mold engineering, injection mold design, mold cavity design, injection molding tools

How does injection molding compare to other manufacturing methods?

Compared to methods like CNC machining or 3D printing, injection molding offers faster production speeds, higher precision for high-volume runs, and lower unit costs over time.

Keywords: injection molding vs machining, injection molding vs 3D printing, manufacturing methods comparison, cost comparison

Custom Injection Molding Manufacturing Article

EPDM Rubber: Properties, Benefits & Custom Molding Solutions

EPDM rubber is a highly versatile and durable material prized for its ability to withstand extreme weather conditions UV rays

A Complete Guide to Silicone Compression Molding

Silicone compression molding is a versatile and efficient manufacturing process used to create high performance silicone rubber parts This technique

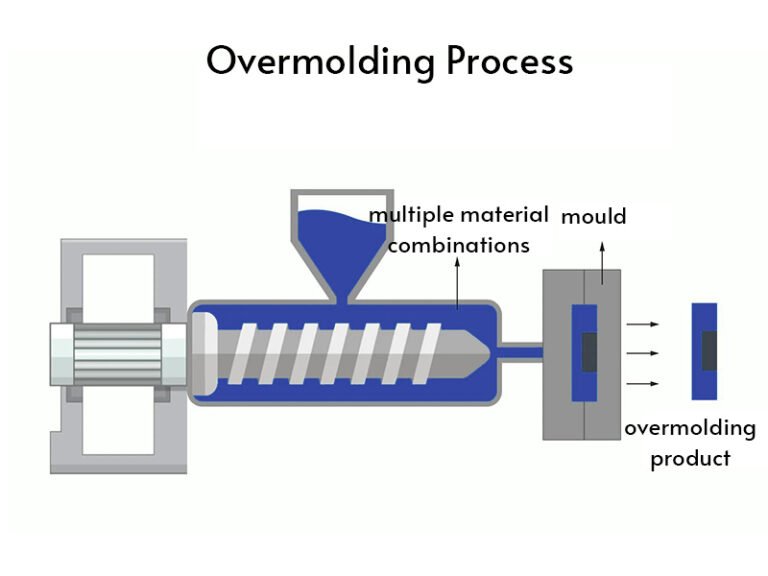

Overmolding Process: Solving Common Manufacturing Challenges in Modern Industries

The overmolding process is a transformative manufacturing technique that enhances the performance durability and aesthetic appeal of products by combining