Automotive Prototyping & Manufacturing

Why Do Automotive Companies Use Jiangzhi

Supply Chain Flexibility

ISO Certified

Strong Production Capacity

Range of Service

Skilled and Experienced

What Materials Work Best for Automotive Parts

Polycarbonate (PC):

Known for its impact resistance and clarity, making it suitable for headlights and transparent components.

Acrylonitrile Butadiene Styrene (ABS):

Provides a good balance of strength and affordability, often used for interior components.

Polypropylene (PP):

Offers excellent chemical resistance and is lightweight, commonly used in automotive bumpers and interior parts.

Polyethylene (PE):

Known for its flexibility and impact resistance, used in various automotive applications.

Polyoxymethylene (POM):

Provides high stiffness and low friction, suitable for precision components like gears and switches.

Nylon (Polyamide):

Known for its strength, heat resistance, and flexibility, used in various automotive parts.

Polyurethane (PU):

Offers excellent abrasion resistance and flexibility, used for seals, gaskets, and suspension components.

Thermoplastic Elastomers (TPE):

Combines characteristics of rubber and plastic, used for flexible components like seals and gaskets.

Auto Parts Processing Service

Trusted by Engineers at Automtoive Companies

Navigating Automotive Manufacturing Challenges with Precision

- Automotive Manufacturers

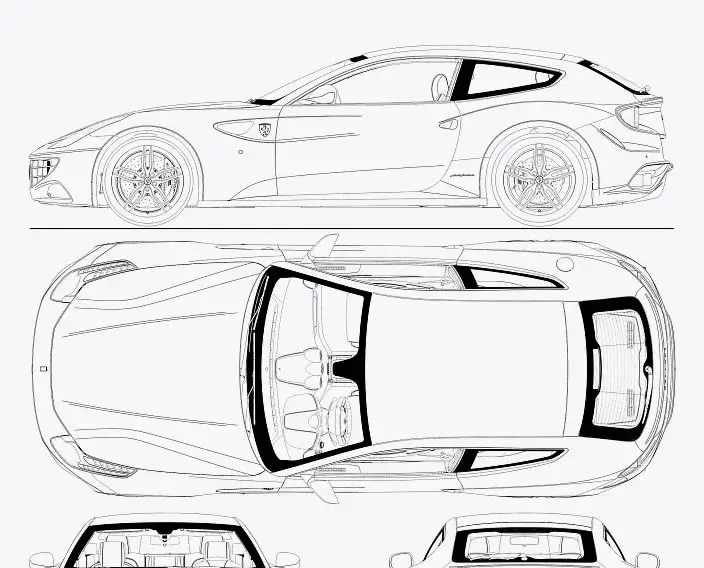

- Automotive Designers and Engineers

- Aftermarket Parts Suppliers

- OEM Suppliers

- Custom Car Builders

- Prototype Developers

- Auto Parts Retailers

Common Automotive Parts

Discover a comprehensive range of rubber and plastic components meticulously engineered for peak performance in modern automobiles. From seals to panels, these materials play a vital role in ensuring safety, durability, and functionality on the road.

- Rubber Seals and Gaskets

- Plastic Dashboard Panels

- Plastic Bumpers and Body Panels

- Rubber O-rings and Sealing Rings

- Rubber Grommets and Plugs

- Plastic Cable Insulation

- Plastic Fuel Tanks

- Plastic Air Intake Components

- Plastic and Rubber Belts

- Rubber Boots for CV Joints

Contract Manufacturing Solution

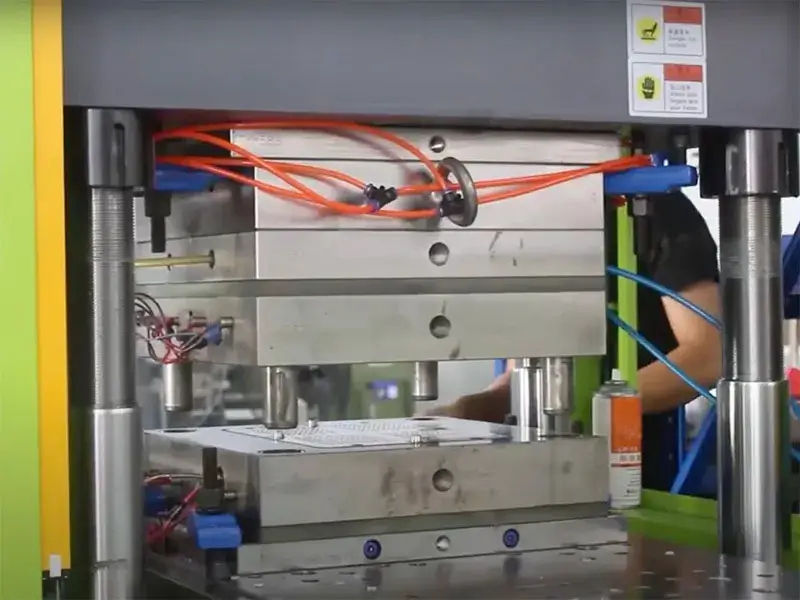

Mold & Tooling Service

Design for Manufacturability

Surface Finishing