Contract Manufacturer for Custom Medical Parts

Why Do Medical Companies Use Jiangzhi

Supply Chain Flexibility

ISO Certified

Strong Production Capacity

Range of Service

Skilled and Experienced

What Materials Work Best for Medical Parts

ABS:

ABS is a versatile thermoplastic with good impact resistance and machinability. It is used in medical equipment casings and housings where durability and ease of processing are important.

Polycarbonate (PC)

Polycarbonate is known for its optical clarity, impact resistance, and ability to withstand repeated sterilization. It is used in medical device components such as lenses and housings.

Polyethylene (PE):

Polyethylene is a versatile material with good chemical resistance. It is utilized in medical packaging, containers, and disposable items.

Polyurethane (PU):

Polyurethane offers flexibility, abrasion resistance, and biocompatibility. It is used in medical tubing, catheters, and implantable devices.

Silicone:

Silicone is valued for its biocompatibility, flexibility, and resistance to extreme temperatures. It is commonly used in medical tubing, seals, and implants.

NBR:

Nitrile rubber provides excellent oil and chemical resistance. It is commonly used in medical gloves and seals.

EPDM:

EPDM offers excellent resistance to heat, ozone, and chemicals. It is used in medical applications, such as seals and gaskets, where resilience and resistance to sterilization processes are crucial.

Fluoroelastomers (FKM/Viton):

FKM exhibits high chemical resistance and is used in medical applications where exposure to harsh chemicals or fluids is expected.

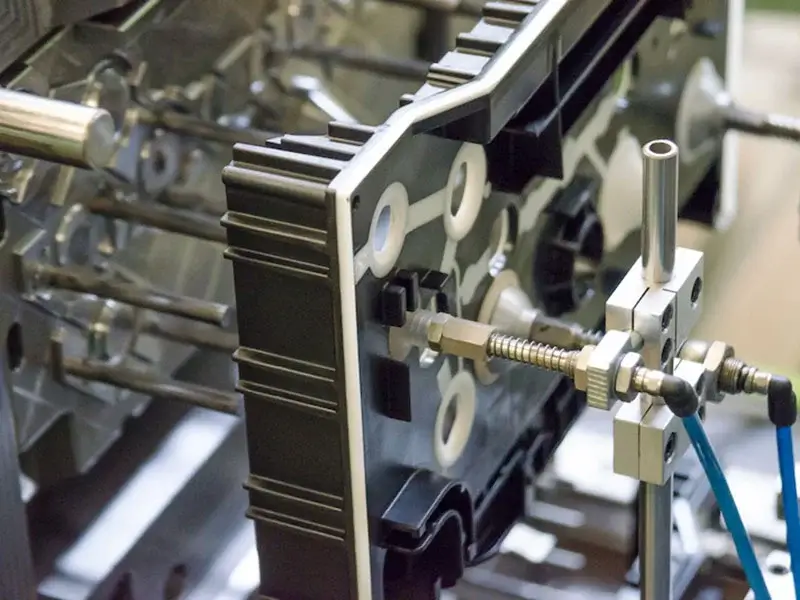

Medical Parts Processing Service

Trusted by Engineers at Medical Companies

Navigating Aerospace Manufacturing Challenges with Precision

- Medical Device Manufacturers

- Biotechnology Companies

- Healthcare Institutions

- Research Institutions

- Pharmaceutical Companies

- Contract Manufacturers

- Dental Product Manufacturers

- Orthopedic Device Manufacturers

- Veterinary Medical Device Manufacturers

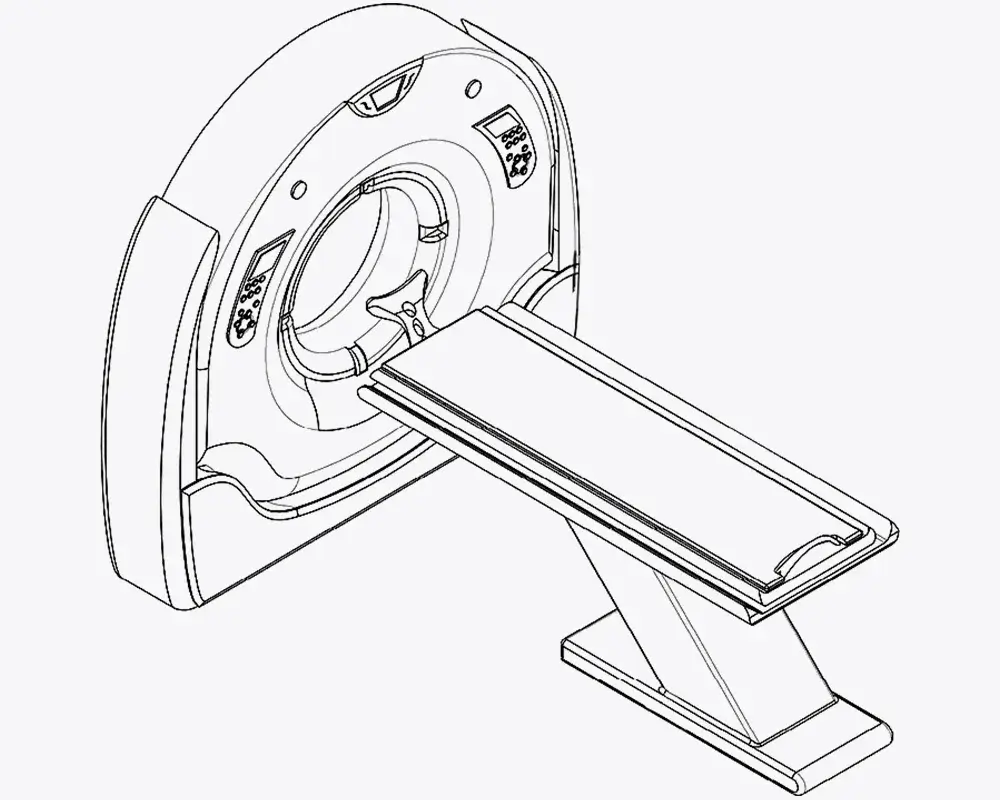

Common Medical Parts

Discover a comprehensive range of rubber and plastic components meticulously engineered for peak performance in medical industry.

- Medical Device Plastic Housings

- Tubing and Connectors

- Plastic Implantable Components

- Diagnostic Equipment Plastic Parts

- Rubber Seals and Gaskets

- Rubber Medical Tubing

- O-Rings

- Other Rubber Medical Sealing Components

Contract Manufacturing Solution

Mold & Tooling Service

Design for Manufacturability

Surface Finishing