Contract Manufacturer for New Energy Parts

Why Do New Energy Companies Use Jiangzhi

Supply Chain Flexibility

ISO Certified

Strong Production Capacity

Range of Service

Skilled and Experienced

What Materials Work Best for New Energy Parts

Acrylonitrile Butadiene Styrene (ABS):

Robust, impact-resistant, and lightweight, ideal for structural components, ensuring durability and agility in robotic systems.

Polypropylene (PP):

Provides chemical resistance and low friction, suitable for robotic parts exposed to various environments and requiring smooth movement.

Polyamide (Nylon/PA):

Combines strength with flexibility, making it suitable for gears and moving parts in robots, ensuring efficient and reliable performance.

Polycarbonate (PC):

Offers high impact strength and transparency, suitable for robotic applications requiring clear or see-through components.

Polyurethane (PU):

Provides excellent abrasion resistance, making it suitable for robotic wheels and components requiring durability and wear resistance.

Silicone Rubber:

Offers flexibility, high-temperature resistance, and electrical insulation, making it suitable for robotic components requiring elasticity and reliability.

Nitrile Rubber (NBR):

Offers sealing properties, shock absorption, and vibration dampening, making it suitable for protective and isolating components in robotics.

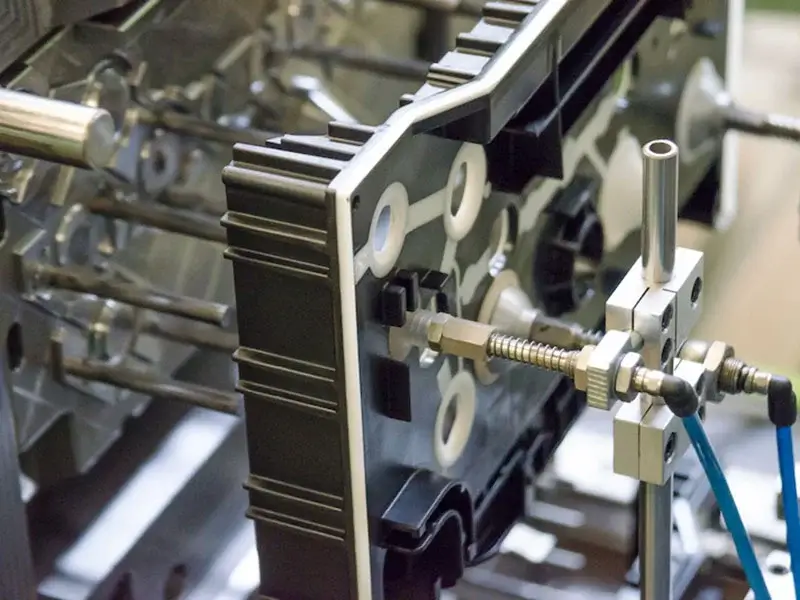

New Energy Parts Processing Service

Trusted by New Energy Companies

Navigating Inudstrial Equipment Manufacturing Challenges with Precision

- Solar Panel Manufacturers

- Battery Manufacturers

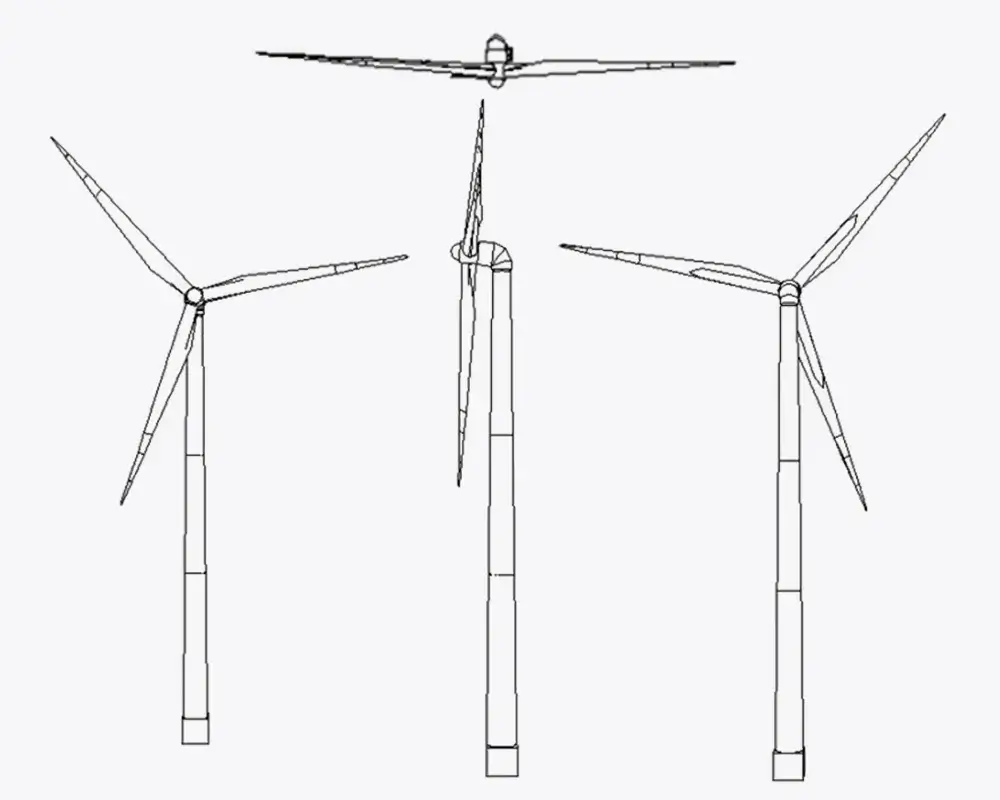

- Wind Turbine Manufacturers

- Electric Vehicle (EV) Manufacturers

- Power Electronics Manufacturers

- Electric Motor Manufacturers

- Renewable Energy Project Developers

Common New Energy Parts

Discover a comprehensive range of rubber and plastic components meticulously engineered for peak performance in new energy applications.

- Polyphenylene Sulfide (PPS) Insulators

- Fluoroelastomer Seals

- Polycarbonate Solar Panel Frames

- Polyamide 66 (PA66) Connectors

- Ethylene Propylene Diene Monomer (EPDM) Gaskets

Contract Manufacturing Solution

Mold & Tooling Service

Design for Manufacturability

Surface Finishing