These days, there is a lot of discussion about micro-injection molding. That reflects the growing needs of designers and manufacturers for high-precision, micro-featured plastic parts. In this post, we’ll delve into the nuances of micro injection molding, exploring its features, types, advantages, and disadvantages, as well as the industries that rely on its capabilities.

What is Micro injection Molding?

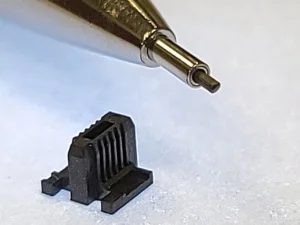

Micro injection molding is a highly specialized manufacturing process used to produce extremely small, high-precision thermoplastic components with micron-level tolerances and intricate features. It involves molding plastic parts that typically weigh less than 1 gram and have dimensions measured in millimeters or microns (1 micron = 0.001 mm). Micro molding can produce parts with tolerances as tight as ±0.003 mm (±0.0001 inches) and features like thin walls (0.1 mm), micro holes, and sharp corners.

The process is similar to traditional injection molding but requires specialized equipment, tooling, and expertise to achieve the necessary precision and accuracy. Molten thermoplastic material is injected into a mold cavity at high pressure, where it quickly cools and solidifies to take the shape of the mold. The mold itself is precision-engineered to create intricate details and features with extreme accuracy.

So in essence, micro injection molding pushes the limits of injection molding to produce intricate plastic components at a micro/miniature scale with extremely tight tolerances.

Types of Micro Injection Molding

2-Shot Micro Molding: Enables the simultaneous molding of two different materials onto the same part in a single mold cycle, allowing for enhanced features or cost savings.

Micro Metal Injection Molding (MicroPIM): Utilizes metal or ceramic powders to create micrometer-sized features. It’s advancing rapidly and enables the production of multi-material items.

Micro Plastic Injection Molding: Used for creating plastic parts with very small tolerances and shot weights. It allows for the production of intricate geometries with high precision.

Micro Transfer Molding (TM): A type of soft lithography where a patterned elastomer is used as a stamp or mold. It finds applications in MEMS devices, microfluidic systems, and various other microfabrication fields.

Each technique serves different purposes and caters to specific requirements in industries ranging from electronics to healthcare.

The Advantages of Micro Injection Molding

High Precision: Ability to create extremely small parts with tight tolerances down to ±0.003 mm (±0.0001 inches) or even smaller. This enables the manufacturing of miniaturized components for industries like medical devices, electronics, optics, etc.

Design Complexity: Capability to mold intricate geometries and features like thin walls (0.1 mm), micro holes, undercuts, threads, etc. that are difficult or impossible with conventional molding. This design flexibility is valuable for complex micro parts.

Material Diversity: Can utilize a wide range of high-performance engineering plastics like PEEK, LCP, COC as well as bioabsorbable polymers to achieve desired material properties. Material selection is critical for micro components.

Consistency and Reproducibility: A highly automated and computerized process allows precise control over molding parameters to achieve exceptional accuracy and repeatability.

Cost-Effectiveness: Cost-effective for high-volume production of micro-sized parts compared to alternative micro-manufacturing methods.

Enables scalability: Improved surface finish quality due to the high precision of micro molding tools and process control. Potential for 24/7 operation to maximize productivity and meet fluctuating demand cycles.

So in essence, micro molding pushes injection molding to its limits to manufacture tiny, intricate plastic components with extremely tight tolerances in a cost-effective and scalable manner for industries requiring miniaturization.

The Disadvantages of Micro Injection Molding

Higher Tooling Costs: Micro molding requires specialized equipment like precision micro molding machines, thin-wall molds, and advanced metrology tools. This specialized tooling and equipment is expensive compared to traditional injection molding.

Longer lead times: Designing and fabricating the ultra-precise micro molds with tiny features can take weeks or months, leading to long lead times before production can begin. Any design changes also require a new mold, further increasing costs and delays.

Material limitations: The high heat and shear forces involved restrict the materials that can be used in micro molding to high-performance engineering plastics like PEEK, LCP, COC etc. Many commodity plastics are unsuitable.

Part Size Limitations: Micro molding is limited to producing extremely small parts, typically weighing less than 1 gram. Larger parts become cost-prohibitive due to the expensive tooling required.

Processing challenges: Achieving uniform plastic flow and consistent part quality is difficult due to the minuscule shot sizes (micro grams) and thin wall sections involved. Precise control over process parameters like temperature and pressure is critical. And require extensive testing and refinement.

Part Ejection and Handling Issues: Handling and ejecting micro-sized parts from the mold can be more challenging than with larger parts. Care must be taken to avoid damage or distortion during ejection, and additional secondary operations may be required to remove flash or burrs from the parts.

Risk of Defects: The small size and intricacy of micro-sized features increase the risk of defects such as sink marks, warpage, and surface imperfections. Maintaining quality control and ensuring dimensional accuracy can be more challenging in micro injection molding. Micromolding requires extensive quality control and monitoring compared to conventional molding.

Limited Production Capacity: A single micro molding machine has relatively low output compared to traditional injection molding machines, potentially limiting production volumes.

Materials for Micro Injection Molding

According to the search results, some of the most common materials used in micro injection molding are:

Engineering Plastics:

- PEEK (Polyetheretherketone)

- LCP (Liquid Crystal Polymers)

- POM (Polyoxymethylene/Acetal)

- PEI (Polyetherimide)

- PSU (Polysulfone)

- PPS (Polyphenylene Sulfide)

- COC (Cyclic Olefin Copolymers)

- Nylon/Polyamide (PA)

- Polycarbonate (PC)

- Acrylic/PMMA

Elastomers/Thermoplastic Elastomers (TPEs):

- TPU (Thermoplastic Polyurethane)

- TPR (Thermoplastic Rubber)

- Liquid Silicone Rubbers (LSR)

The choice depends on factors like mechanical properties, biocompatibility, optical clarity, and heat resistance needed for the specific micro application.

while commodity plastics can potentially be used for micro injection molding, the process may require significant optimization and expertise to achieve the extremely tight tolerances required, compared to higher-performance engineering polymers better suited for micro applications.

Common Products Types by Micro Injection Molding

Micro injection molding is commonly used to produce extremely small, high-precision plastic components for various industries, including:

Medical Devices

- Micro implants (stents, drug delivery devices)

- Micro fluidic systems (lab-on-a-chip devices, micro-pumps)

- Surgical instruments and tools

- Micro sensors and probes

Electronics and Semiconductors

- Micro connectors and sockets

- Micro gears and mechanical components

- Chip carriers and holders

- Micro lenses and optical components

Automotive and Aerospace

- Micro sensors and actuators

- Micro filters and nozzles

- Precision micro components

Consumer Products

- Micro mechanical parts (watches, pens, toys)

- Micro fasteners and hardware components

- Micro bezels and decorative trim pieces

Conclusion

In conclusion, while conventional injection molding has long been the backbone of manufacturing, its limitations become apparent when faced with the demand for smaller, more intricate parts. Micro injection molding is a precise and compact solution tailored to meet the evolving needs of various industries. This specialized technique offers a multitude of advantages, from unparalleled precision to cost-effectiveness for small-scale production runs.