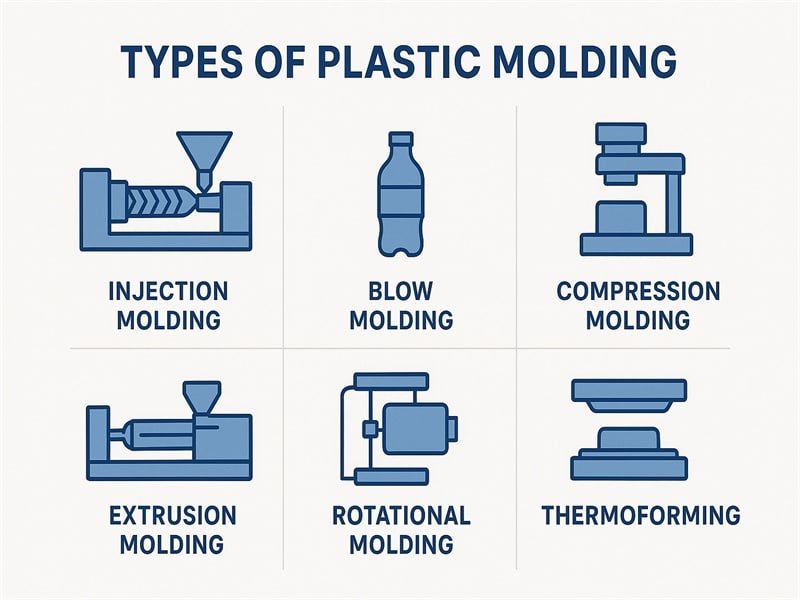

Understanding the various plastic molding types is essential for choosing the right manufacturing process for any plastic product. From high-precision automotive parts to lightweight consumer packaging, each type of molding plastic offers distinct advantages depending on design complexity, material selection, and production volume. Whether optimizing for durability, complexity, or cost-efficiency, selecting the appropriate moulding type is a critical step in product development and large-scale manufacturing.

This article explores the most common types of plastic molding, including injection molding, blow molding, compression molding, extrusion, rotational molding, and thermoforming. We’ll highlight their process characteristics, applications, and key strengths to help you determine the best fit for your project.

Injection Molding

Among the most widely used types of plastic moulding, injection molding stands out for its versatility and precision. In this process, molten plastic is injected into a steel or aluminum mould cavity at high pressure. There are several types of injection molding, including:

- Insert molding (embedding inserts like metal during molding).

- Overmolding (molding over a previously molded part).

- Two-shot molding (injecting two materials in sequence).

- Large part injection molding (used for automotive or appliance panels).

These types of plastic injection moulding are ideal for projects requiring detailed geometries, repeatability, and fast cycle times.

Main Applications

This method accommodates a variety of materials, including thermoplastics such as ABS, polycarbonate, and nylon, as well as thermosets and elastomers, making it ideal for producing high-volume components with tight tolerances and complex geometries. It is widely used in sectors such as automotive, medical device housings, and consumer electronics.

Advantages and Disadvantages

Injection molding offers exceptional dimensional accuracy, repeatability, and efficiency for mass production. However, it requires high upfront tooling costs 、demands precise mould design and specialized machinery for different molding techniques.

Blow Molding

Blow molding forms hollow plastic products by inflating a heated plastic tube (parison) inside a mold cavity. The main types include extrusion blow molding, injection blow molding, and stretch blow molding, each suited to different performance and production needs. In extrusion blow molding, a continuous tube of molten plastic is extruded and then inflated into the mold cavity. Injection blow molding, on the other hand, involves injecting molten plastic into a preform mold, which is then inflated to form the desired shape. Stretch blow molding stretches the preform while blowing it.

Main Applications

It is the process of choice for producing hollow containers such as bottles, tanks, and jugs. The stretch blow molding variant is especially common for PET beverage bottles.

Advantages and Disadvantages

Blow molding is highly efficient for producing uniform wall thickness in hollow parts. It offers low cycle times and cost-effective tooling. However, the process is limited to hollow designs and may require secondary trimming for flash.

Compression Molding

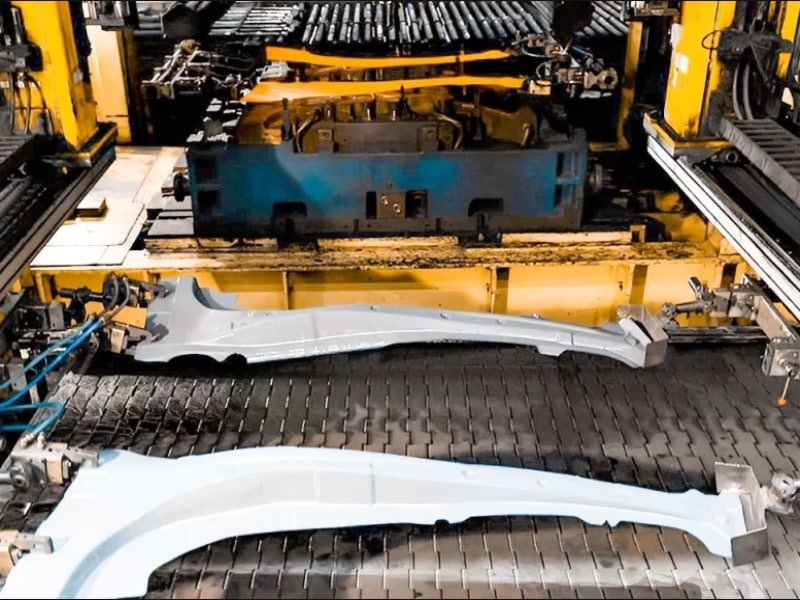

A classic method among moulding techniques, compression moulding involves placing a pre-measured charge of material into an open mould, which is then closed and heated under pressure. This method is well-suited for creating large, thick, and structurally robust parts, often made from thermosets like epoxy, phenolic, and BMC (bulk molding compound).

Main Applications

Commonly used in automotive exterior panels, electrical insulation parts, and composite structural components.

Advantages and Disadvantages

The process offers notable advantages, such as the ability to produce high-strength components with minimal material waste, and is well-suited for parts requiring high rigidity and durability. However, it also has its drawbacks, including slower cycle times compared to injection molding and the limited material options since it is primarily used for thermoset plastics. Additionally, the molding process may be less precise, making it unsuitable for parts requiring very fine details or tight tolerances.

Extrusion Molding

Extrusion molding pushes molten plastic through a die to create continuous shapes with consistent cross-sections. This is one of the most cost-effective types of moulding for products with long profiles.

Main Applications

Widely used for producing tubes, pipes, sheets, window profiles, and films in both industrial and consumer applications.

Advantages and Disadvantages

Extrusion molding is ideal for high-throughput, low-cost manufacturing of long plastic profiles. It ensures excellent dimensional consistency over extended lengths. However, it’s limited to parts with consistent cross-sections and may exhibit surface defects if cooling isn’t uniform.

Rotational Molding

Also known as rotomolding, rotational molding involves heating and rotating a mold to form hollow parts. This process stands out among plastic molding types for its ability to create seamless parts without weld lines.

Main Applications

Ideal for large, stress-free hollow items such as water tanks, playground equipment, kayaks, and outdoor furniture.

Advantages and Disadvantages

Rotational molding boasts low tooling costs and is capable of producing parts with uniform wall thickness and zero weld lines. However, it has longer cycle times and is generally unsuitable for fine-detail or thin-walled parts.

Thermoforming

Thermoforming involves heating plastic sheets until pliable and then forming them over a mold using vacuum pressure or compressed air. Vacuum forming is simpler and less expensive, while pressure forming provides sharper details and better definition.

Main Applications

Extensively used in disposable packaging, clamshell containers, instrument panels, and lightweight enclosures.

Advantages and Disadvantages

This process allows for rapid prototyping, low tooling costs, and fast turnaround. However, it is limited to single-sided parts and lacks the structural integrity offered by other molding techniques.

Conclusion

There are many types of molding plastic, each with unique advantages and limitations. From injection molded plastic components to custom blow-molded containers, the correct choice depends on product complexity, volume, material, and cost.By aligning manufacturing methods with functional requirements, material constraints, and aesthetic expectations to choose the suitable molding type for the project.

By understanding the different plastic moulding types—from thermoforming to rotational molding—manufacturers can align production strategies with performance goals and budget. If you’re evaluating plastic molding manufacturers, be sure they have expertise in multiple moulding techniques and offer support in moulding design to streamline the development process and maximize results.