Precision CNC turning is a cutting-edge manufacturing process that delivers unmatched accuracy and efficiency in the production of cylindrical and complex parts. This highly specialized technique plays a crucial role in industries ranging from aerospace to automotive, where precision and tight tolerances are paramount. In this article, we will explore the fundamentals of precision CNC turning, the various types of processes involved, the materials used, and the advantages it offers over other machining methods. Additionally, we will highlight its diverse applications and how it compares to precision CNC milling, providing a comprehensive guide to understanding this vital manufacturing technique.

What is Precision CNC Turning?

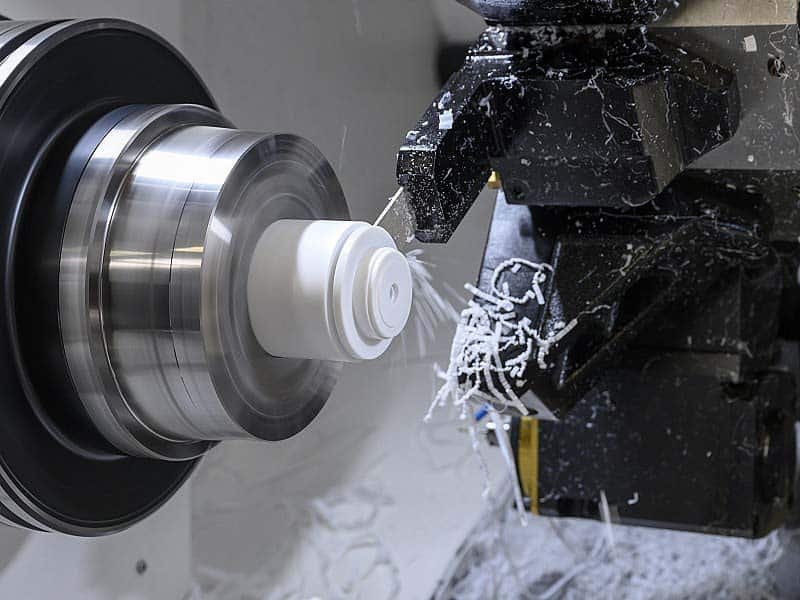

Precision CNC turning is a sophisticated machining process that utilizes computer numerical control (CNC) to automate the turning of a workpiece. This process is employed to produce highly accurate, symmetrical parts with complex geometries, typically cylindrical in shape. The CNC turning machine uses a rotating cutting tool to remove material from the workpiece, shaping it to the required dimensions. Precision in this process refers to the ability to achieve tight tolerances and fine surface finishes that are critical in industries like aerospace, automotive, medical, and electronics.

Precision CNC turning differs from traditional turning in that it involves the use of CNC technology to precisely control every aspect of the cutting process. This automation allows for a higher degree of consistency, repeatability, and accuracy compared to manual methods. CNC turning is particularly valued for its ability to produce complex features such as grooves, threads, and tapering with exceptional precision, making it ideal for high-performance applications.

Key Techniques in Precision CNC Turning

1. Turning Operations

Turning is the foundational operation in cnc turning part manufacturing, where the cutting tool moves parallel to the axis of rotation. It can produce straight or tapered surfaces, allowing for high precision in creating components like shafts and bushings.

2. Threading and Tapping

Threading: This involves cutting helical grooves into a workpiece to create internal or external threads. Precision threading tools ensure consistent pitch and depth, crucial for fasteners used in various applications.

Tapping: Similar to threading but specifically for creating internal threads within holes, tapping ensures precise thread sizes for fasteners, enhancing assembly accuracy.

3. Facing

Facing cuts across the end of a workpiece to create a flat surface perpendicular to its axis. This process is vital for ensuring precise lengths and surface finishes, preparing parts for further machining operations.

4. Boring

Boring enlarges existing holes with high accuracy, ensuring tight tolerances for internal diameters. It is commonly used in applications requiring precise internal features, such as bearing seats in automotive components.

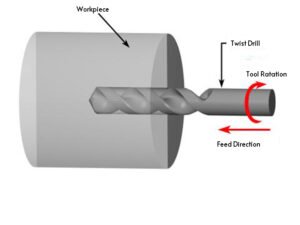

5. Drilling and Reaming

Drilling: Involves creating holes along the workpiece’s axis with rotating drill bits. Techniques like spot drilling and peck drilling enhance precision during this operation.

Reaming: This technique refines drilled holes to achieve superior dimensional accuracy and surface quality, essential for parts requiring tight tolerances.

6. Grooving and Knurling

Grooving: Often referred to as parting, this technique involves cutting away sections of the workpiece to create grooves or notches.

Knurling: This process creates a pattern on the surface of a workpiece to improve grip, commonly used on handles and knobs.

Common Materials Used in Precision CNC Turning

The materials selected for CNC turning are crucial to ensuring that the finished product meets the required specifications and performs optimally in its application. Here are some common materials used in precision CNC turning:

Metals:

- Aluminum: Lightweight, corrosion-resistant, and easy to machine, aluminum is often chosen for its excellent balance of strength and weight. It is widely used in industries such as aerospace, automotive, and electronics.

- Stainless Steel: Known for its strength and resistance to corrosion, stainless steel is frequently used in applications where durability and longevity are critical, such as in medical devices and automotive components.

- Titanium: Although challenging to machine due to its hardness, titanium is highly valued for its strength-to-weight ratio and resistance to corrosion. It is commonly used in aerospace and medical implants.

- Brass and Copper: These metals are easy to machine and have excellent thermal and electrical conductivity. They are often used in the manufacturing of components like electrical connectors, heat exchangers, and valves.

Plastics:

- Acrylic: Lightweight and versatile, acrylic is often used in applications that require transparency, such as in the production of optical lenses and display screens.

- Nylon: Known for its strength, wear resistance, and low friction properties, nylon is used in producing gears, bushings, and bearings.

- Polycarbonate: Polycarbonate is a tough, impact-resistant plastic commonly used in applications requiring optical clarity, such as in eyewear lenses and protective covers.

Composites:

Composite materials, often made from a combination of fibers and resins, are becoming more popular in precision CNC turning. These materials offer a combination of lightweight properties and strength, making them suitable for high-performance applications.

Advantages of Precision CNC Turning

Precision CNC turning offers numerous advantages that make it the go-to method for high-precision part manufacturing.

High Accuracy and Tolerances

One of the most significant benefits of precision CNC turning is its ability to achieve extremely tight tolerances. CNC machines are programmed to make fine adjustments during the turning process, ensuring that each part meets exact specifications. This accuracy is essential for industries like aerospace, medical devices, and automotive, where small deviations can lead to product failure.

Efficiency and Repeatability

CNC turning machines can produce high volumes of parts quickly and consistently. Once the CNC program is set up, the machine can run continuously, producing identical parts with minimal human intervention. This repeatability is vital for large-scale production runs and helps to reduce costs.

Complex Geometries

CNC turning can handle complex part designs that would be difficult, if not impossible, to achieve with manual turning. The ability to produce intricate shapes, detailed grooves, threads, and tapers makes CNC turning ideal for producing high-performance components used in demanding applications.

Cost-Effectiveness for Medium to Large Runs

While the initial setup cost for CNC turning can be high, it becomes cost-effective for medium to large production runs. The automation and speed of CNC turning reduce the labor costs and minimize the risk of errors, making it an excellent choice for large-scale manufacturing.

Applications of CNC Turning Service

The versatility of precision CNC turning makes it suitable for a wide range of industries. Here are some of the most common applications:

Aerospace

In the aerospace industry, CNC turning is used to manufacture parts such as turbine blades, housings, and structural components. These cnc turned parts require high precision and durability, and CNC turning’s ability to produce tight tolerances makes it a key process in aerospace manufacturing.

Automotive

CNC turning plays a crucial role in producing automotive components, including gears, shafts, and bushings. The process ensures that these cnc turned parts are made to exact specifications, which is essential for the performance and safety of vehicles.

Medical Devices

Medical devices require parts that are both highly accurate and made from materials that are safe for use in the human body. CNC turning is often used to create components like surgical tools, implants, and precision fittings for medical equipment.

Electronics

In electronics, CNC turning service is used to manufacture parts like connectors, housings, and terminals. The precision and repeatability of the process ensure that these components fit together perfectly and function as intended.

Difference Between Precision CNC Turning and Precision CNC Milling

While both precision CNC turning and precision CNC milling are advanced machining processes, they differ in how they operate and the types of parts they are suited for.

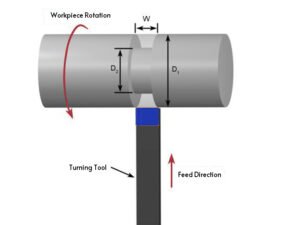

Process

In CNC turning, the workpiece rotates, and a fixed cutting tool removes material. In contrast, CNC milling involves a stationary workpiece and rotating cutting tools that move across the material to remove it. This fundamental difference gives CNC turning the edge in producing cylindrical parts, while CNC milling excels in creating parts with more complex, non-cylindrical geometries.

Applications

CNC turning is typically used for parts that are round or cylindrical, such as shafts, bushings, and valve bodies. On the other hand, CNC milling is better suited for parts that have irregular shapes or require more intricate features, such as pockets, slots, and flat surfaces.

Accuracy and Speed

Both CNC turning and CNC milling can achieve high precision, but CNC turning is generally faster for parts that involve simple rotations. CNC milling, while slightly slower, offers greater versatility for parts with detailed features.

Here is a comparison table Summarize the different between CNC Turning and CNC Milling.

| Aspect | CNC Turning | CNC Milling |

|---|---|---|

| Process | The workpiece rotates while a stationary tool removes material. | The workpiece remains stationary while rotating tools cut the material. |

| Ideal Geometry | Best for cylindrical, spherical, and conical parts. | Suitable for parts with irregular shapes, flat surfaces, and complex features. |

| Cutting Tool Movement | The cutting tool moves in a linear motion along the X, Y, and Z axes. | The cutting tool moves in multiple directions (X, Y, Z axes) and can rotate around the workpiece. |

| Part Size | Typically used for smaller, round parts. | Suitable for larger and more complex parts, including flat surfaces and intricate shapes. |

| Applications | Shafts, bushings, valve bodies, rings, and other rotational parts. | Parts requiring detailed features, such as pockets, slots, flat surfaces, and non-cylindrical shapes. |

| Speed | Generally faster for simple, repetitive turning of cylindrical shapes. | Slightly slower than turning but offers more versatility in shape complexity. |

| Precision & Accuracy | High precision, especially for parts with cylindrical geometry. | High precision for intricate shapes and surface finishes, including both flat and 3D features. |

| Material Removal | Removes material from a rotating workpiece with minimal tool engagement. | Removes material with more intricate movements, allowing for complex geometries. |

| Tooling Requirements | Simple tooling, generally one tool is used for multiple cuts. | Requires a range of tooling options, including drills, mills, and taps. |

| Cost | Typically less expensive for simpler, round parts in high volumes. | More expensive for complex, detailed parts but offers flexibility for different geometries. |

Conclusion

Precision CNC turning is an essential process in modern manufacturing, offering high accuracy, repeatability, and the ability to create complex geometries. With applications spanning industries from aerospace to medical devices, CNC turning enables the production of parts that meet the most stringent requirements. By understanding the different types of CNC turning processes, materials used, and advantages of the method, manufacturers can select the best approach to achieve the desired results. Whether you are producing small batches or large volumes of precision components, CNC turning service provides an efficient and reliable solution for your manufacturing needs.