Rapid injection molding is revolutionizing the manufacturing landscape, offering a fast and efficient solution for producing high-quality plastic parts in shorter timeframes. Unlike traditional methods, this innovative process enables companies to quickly prototype and manufacture low to medium-volume parts, significantly reducing lead times and costs. In this article, we delve into the core principles of rapid injection molding, explore its key benefits, and examine how it compares to traditional injection molding. Whether you’re looking to streamline your production process or bring prototypes to life with speed and precision, understanding rapid injection molding is essential for staying ahead in today’s competitive market.

What is Rapid Injection Molding?

Rapid injection molding is a manufacturing technique that allows the production of plastic parts in a significantly reduced timeframe compared to traditional injection molding. This process utilizes specialized, often less expensive, tools and molds designed for speed, making it ideal for low-to-medium volume production, rapid prototyping, and quick design iterations. The use of rapid tooling and optimized machine settings enables manufacturers to produce high-quality parts swiftly, making this method highly advantageous for industries that require fast turnaround times, such as automotive, electronics, and medical device manufacturing.

The core advantage of rapid injection molding lies in its ability to quickly translate designs into physical products, allowing businesses to test and iterate product concepts before committing to large-scale manufacturing. This process ensures a faster route to market while reducing both costs and the time typically associated with conventional molding methods.

Key Benefits of Rapid Injection Molding

Rapid injection molding offers several compelling advantages, particularly for businesses looking to accelerate product development and reduce time to market.

1. Reduced Lead Times

One of the most significant benefits of rapid injection molding is the drastic reduction in lead times. By using rapid tooling and advanced manufacturing techniques, the process can deliver prototypes and production parts in days instead of weeks, allowing manufacturers to quickly assess the form, fit, and function of their designs.

2. Cost Efficiency for Low-to-Medium Production

Unlike traditional injection molding, which often requires expensive molds and lengthy setup times, rapid injection molding uses cheaper, quicker-to-manufacture molds. This makes it particularly cost-effective for low-volume production runs or bridge production—when a company needs a small quantity of parts before full-scale manufacturing begins.

3. Design Flexibility

Rapid injection molding offers more flexibility in terms of design changes. Since the tools and molds are simpler and faster to modify, engineers can easily adjust part designs or make refinements in response to testing and customer feedback. This flexibility accelerates the product development cycle and helps reduce the likelihood of costly errors or delays.

4. Faster Prototyping and Testing

For companies developing new products, rapid injection molding is an essential tool. It enables engineers to quickly create prototypes, test them for functionality, and make adjustments based on real-world performance, all within a short timeframe.

5. Quick Turnaround for Prototypes and Production Parts

Rapid injection molding supports both prototype and production runs, making it an ideal choice for companies that need functional parts within tight timeframes. Whether creating prototypes for testing or producing parts for a limited run, this technique ensures that designs can be finalized and manufactured in a fraction of the time compared to traditional methods.

How Rapid Injection Molding Works?

The rapid injection molding process is designed to be more streamlined and efficient than traditional molding. The key elements of the process are:

1. Rapid Tooling

The foundation of rapid injection molding is the use of rapid tooling. This method uses softer, quicker-to-produce molds made from materials such as aluminum or steel, as opposed to the more complex, time-consuming molds used in traditional injection molding. These tools can be produced in just a few days, allowing manufacturers to begin production much faster.

2. Injection Molding Process

Once the mold is ready, the process begins. Plastic pellets are heated until they melt and are then injected into the mold cavity under high pressure. The molten plastic fills the mold, taking the shape of the desired part. After cooling and solidifying, the mold is opened, and the part is ejected. The rapid injection molding process often uses automated systems to maintain precision and consistency, ensuring that the final product meets the required specifications.

3. Material Selection

The choice of material plays a critical role in rapid injection molding. The materials used are typically standard thermoplastics, including ABS, polypropylene, polycarbonate, and nylon. However, with advances in rapid molding, more specialized materials can now be used, depending on the needs of the product being created.

Rapid Molding Equipments

Rapid prototyping requires various types of equipment, depending on the chosen manufacturing technology. Here are some common types of equipment used in rapid prototyping, categorized by the different techniques:

1. 3D Printers

It can directly generate parts from CAD files without the need for traditional molds. It used for creating prototypes, verifying designs, or even small batch production. Common 3D printing technologies include FDM (Fused Deposition Modeling), SLA (Stereolithography), and SLS (Selective Laser Sintering).

2. CNC Machines

Used to precisely cut and carve parts from metal or plastic blocks. Common equipment includes CNC milling machines and CNC lathes. CNC machines suitable for prototypes or small batch production requiring high precision, and can produce complex geometries quickly.

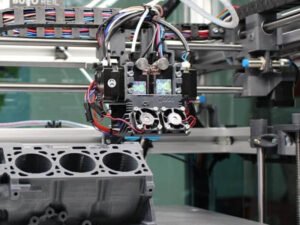

3. Rapid Injection Molding Machines

Similar to traditional injection molding machines, typically use aluminum molds, which are faster and less expensive to produce compared to traditional steel molds, making them ideal for low-volume production and prototype testing.

4. Laser Sintering Equipment (SLS)

Uses a laser to melt powder materials (such as plastics, metals, or ceramics) layer by layer to build up parts. Does not require additional support structures and can create complex internal geometries, commonly used for functional prototypes and low-volume production.

5. Vacuum Casting Equipment

Involves using silicone molds to cast liquid materials (such as resins or rubbers) into molds under a vacuum to reduce air bubbles and create high-precision parts. Ideal for small batch production, especially when tooling costs are high or production timelines are tight.

Differences Between Traditional and Rapid Injection Molding

While both rapid injection molding and traditional injection molding rely on the same fundamental process, there are distinct differences that set them apart:

1. Tooling and Mold Design

In traditional injection molding, the molds are made from hardened steel, which can take several weeks to produce and is costly. These molds are designed for high-volume, long-term production runs. In contrast, rapid injection molding uses simpler, often aluminum molds that can be produced in a fraction of the time. Rapid molds are intended for shorter runs and prototyping, making them a more affordable option for smaller batches.

2. Lead Time

Traditional injection molding involves a longer lead time due to the time required to design and manufacture the molds. With rapid injection molding, the lead time is significantly reduced due to the faster mold production process. Prototypes and short-run production parts can be created in just days or weeks, not months.

3. Cost of Production

The cost per unit in traditional injection molding tends to be lower in high-volume production runs because the molds are built to last and the costs are spread across a large number of parts. However, rapid injection molding is more cost-effective for low-volume production or prototyping, as the tools and molds are less expensive and quicker to make. For smaller runs, this can make a significant difference in cost efficiency.

4. Volume Flexibility

Traditional injection molding is ideal for high-volume production, where thousands or millions of parts are needed. Rapid injection molding, on the other hand, is more suited to low- and medium-volume production, such as prototype testing or small batch manufacturing. It provides manufacturers with flexibility in volume while still ensuring high-quality output.

Here’s a table that summarizes the key differences between traditional and rapid injection molding:

| Aspect | Traditional Injection Molding | Rapid Injection Molding |

|---|---|---|

| Tooling and Mold Design | Uses high-quality, hardened steel molds that are expensive and time-consuming to produce | Uses faster, cheaper molds (typically aluminum) designed for quick turnaround and smaller runs |

| Lead Time | Longer lead times due to mold design and fabrication process (several weeks to months) | Shorter lead times, often just days or weeks due to faster mold production and setup |

| Cost of Production | Lower per unit cost for high-volume production runs, but high initial setup cost | Higher per unit cost for smaller runs, but lower setup cost for low-volume or prototype runs |

| Volume Flexibility | Best suited for high-volume, long-term production (thousands to millions of parts) | Ideal for low- to medium-volume production (small batches or prototypes) |

| Design Iterations | Less flexibility in making design changes once production begins | Offers more flexibility to make quick design changes and iterations due to faster mold adjustments |

| Tool Durability | Molds are built for long-term use and durability, suitable for continuous high-volume runs | Molds are designed for short-term use, often only good for low-volume production or prototyping |

| Material Variety | Can accommodate a wide range of materials, including specialized and high-performance plastics | Typically uses standard thermoplastics, though some advanced materials can be used for rapid molding |

| Application | Best for large-scale manufacturing where economies of scale make it cost-effective | Best for prototyping, low-to-medium volume production, or situations that require fast turnaround times |

Common Applications of Rapid Injection Molding

Rapid injection molding is widely used across several industries where speed, cost-efficiency, and high-quality outputs are essential. Some of the most common applications include:

1. Prototyping and Product Development

Rapid injection moulding is an excellent choice for prototyping, allowing engineers to quickly produce functional parts for form, fit, and function testing. This process enables companies to identify design flaws, test materials, and make adjustments rapidly, significantly reducing the overall time spent on product development.

2. Small Batch Production

For low- to medium-volume production runs, rapid injection molding offers a cost-effective and fast alternative to traditional methods. Industries such as automotive, electronics, and consumer goods often use rapid injection molding for short-run manufacturing needs, ensuring parts can be produced quickly without the need for large-scale tooling investments.

3. Customization and Specialized Components

Rapid injection molding is particularly useful for the production of customized or specialized parts, particularly in industries like medical devices, automotive, and aerospace, where small quantities of high-performance components are required for testing, validation, or niche applications.

4. Injection Molding for Prototypes

Rapid injection moulding is often used to create functional prototypes that can be tested for performance, durability, and other critical factors. These prototypes can be used for design verification, ensuring that the product performs as expected before moving on to full-scale manufacturing.

Conclusion

Rapid injection molding provides significant advantages in terms of speed, cost, and flexibility, making it an invaluable tool for industries focused on innovation and quick product development. By using rapid tooling and a streamlined process, manufacturers can quickly transition from concept to prototype to production, all while maintaining high-quality standards. As industries continue to evolve and demand faster turnaround times, rapid injection molding will play an increasingly important role in shaping the future of manufacturing.

With its ability to support rapid prototyping, low-volume production, and fast iteration cycles, rapid injection molding is becoming a critical enabler of efficient product development and reduced time-to-market. Whether used for prototypes, small batches, or custom components, this method offers significant benefits in the fast-paced world of modern manufacturing.