Rubber molded components are everywhere — from automotive seals to medical devices and industrial gaskets. But what is rubber molded and how exactly is rubber turned into complex, durable parts?

In this guide, we’ll walk you through the rubber molding process, different rubber molding methods, materials you can choose from, and how to pick the right solution for your application.

What Is Rubber Molded?

Rubber molded products are components that are shaped by placing raw rubber into a mold and applying heat and pressure. This process forces the rubber to conform to the shape of the mold cavity, resulting in custom-shaped, high-precision parts.

In industries like automotive, electronics, medical, and industrial equipment, molded rubber is used for its elasticity, resistance to heat and chemicals, and ability to create airtight and watertight seals.

How Is Rubber Moulded?

So, how is rubber moulded into final parts? The rubber molding process typically involves three main steps:

- Preparing the Rubber Material–The rubber (natural or synthetic) is compounded with additives to improve performance, then cut into preforms.

- Placing in Mold Cavity–The rubber preform is placed into a mold made from metal (usually aluminum or steel) that reflects the shape of the final part.

- Heating & Pressurizing–The mold is closed and heated. Under pressure, the rubber flows and fills the cavity, then cures (vulcanizes) to harden into the desired shape.

Common Types of Rubber Molding Processes

There are three major rubber molding methods, each suited to different part geometries and production volumes:

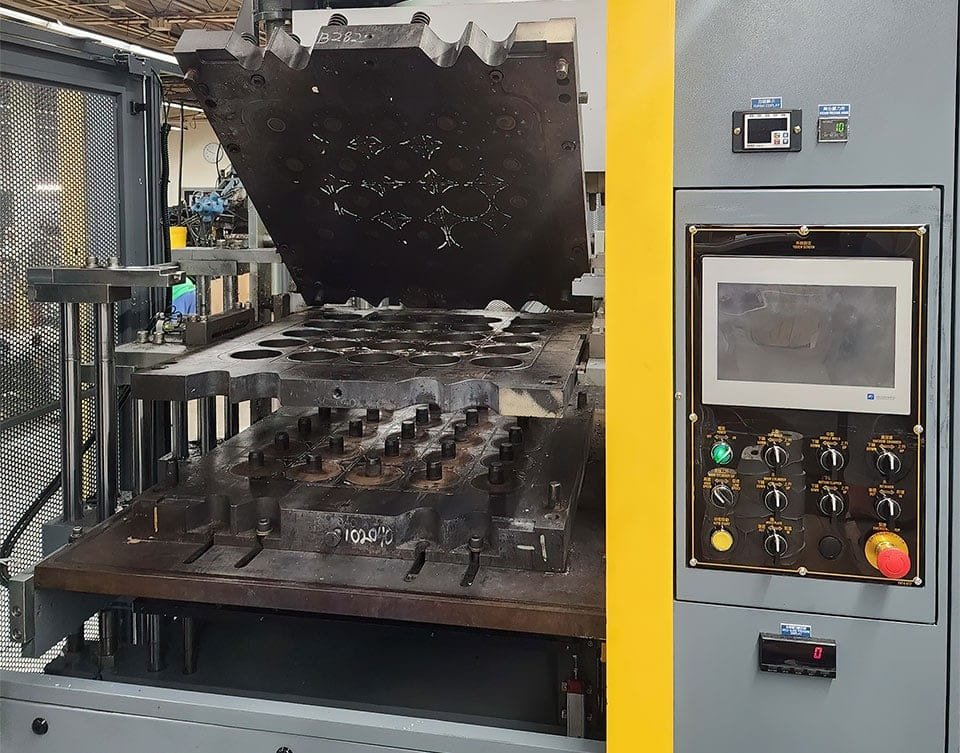

1. Compression Molding

Compression molding is one of the oldest and most straightforward rubber molding techniques. A pre-measured amount of rubber (called a preform) is placed into an open mold cavity. The mold is then closed and pressure is applied, causing the rubber to flow and fill the shape.

Key Features:

- Lower tooling cost

- Ideal for medium-to-large parts

- Long curing cycle

- More material waste (flash)

Best Suited For:

- Low to medium volume production

- Thick, simple parts with minimal undercuts

- Rubber products like gaskets, bumpers, vibration mounts, seals

Case Example:

A manufacturer producing large industrial gaskets in batches of 500 may use compression molding to save on tooling and allow easy material changes.

2. Transfer Molding

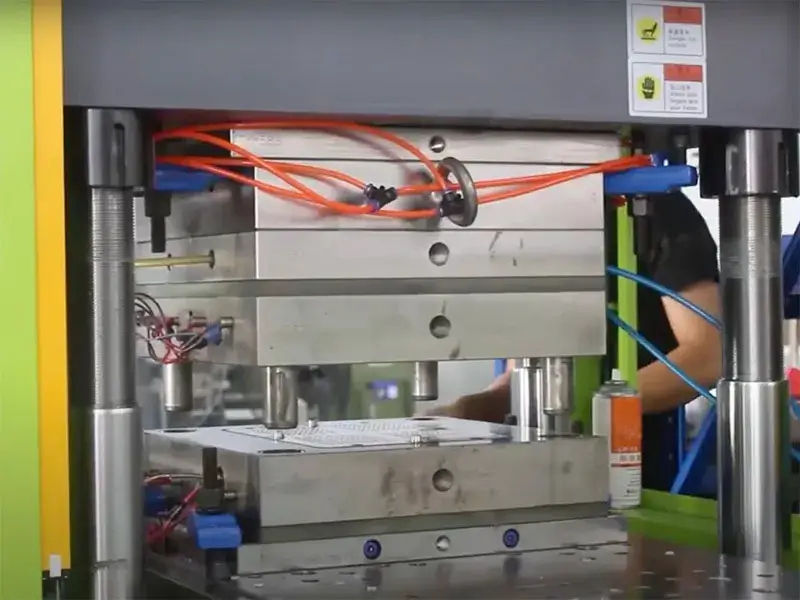

Transfer molding bridges the gap between compression and injection molding. Rubber is loaded into a pot (transfer chamber) and then pushed through sprues into the closed mold cavity under pressure.

Key Features:

- Better dimensional control than compression molding

- Fewer defects like voids or air pockets

- Suitable for insert molding (e.g., bonding metal and rubber)

- Slightly higher tooling cost

Best Suited For:

- Moderate volume

- Medium-complexity geometries

- Parts requiring embedded components (metal, plastic, mesh)

Case Example:

An electronics company may use transfer molding to create rubber switch covers over PCB components, ensuring tight seals around inserts.

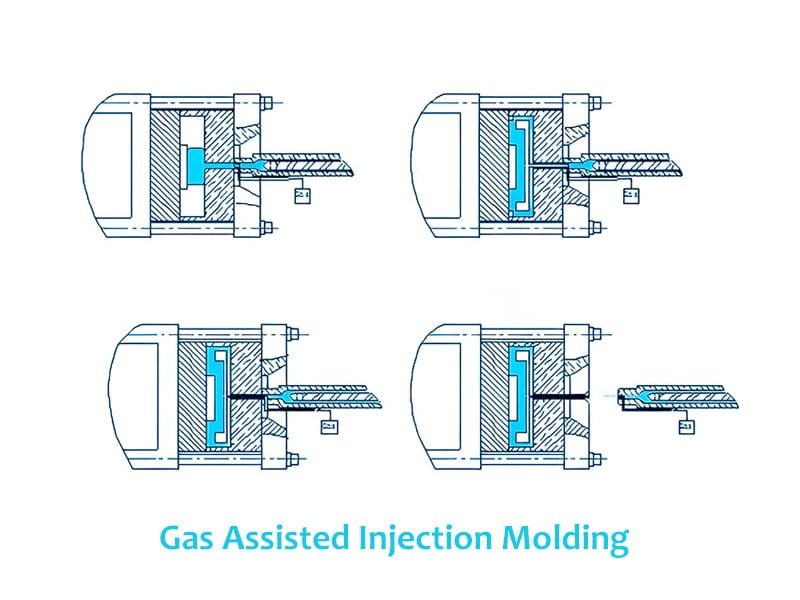

3. Injection Molding

Rubber injection molding is the most automated and precise method. Preheated rubber is injected into a closed, temperature-controlled mold at high pressure, allowing for fast, repeatable cycles.

Key Features:

- High efficiency and consistency

- Minimal flash and reduced post-processing

- Ideal for high-volume production

- Higher tooling investment

Best Suited For:

- High-volume runs

- Complex shapes with tight tolerances

- Small to medium-sized parts

Case Example:

A medical device company producing thousands of silicone valve seals monthly would benefit from rubber injection molding for speed, sterility, and repeatability.

Each rubber molding process has its own benefits. Choosing the right one depends on part complexity, quantity, and material.

Rubber Materials for Molding

There are many rubber molding compounds available, each offering different properties. Some common options include:

- Natural Rubber (NR): Excellent elasticity and low-temperature flexibility.

- EPDM: Great weather and ozone resistance — ideal for outdoor applications.

- Nitrile (NBR): Resistant to oils and fuels — popular in automotive and industrial parts.

- Silicone (VMQ): Wide temperature range and biocompatibility — common in food and medical uses.

- Neoprene (CR): Balanced strength and flexibility — suitable for various general-purpose components.

- Fluoroelastomer (FKM/Viton): Outstanding chemical and heat resistance — used in aerospace and fuel systems.

Examples of Molded Rubber Products

Rubber molded parts appear across nearly every industry. Typical products include:

- Automotive: Grommets, seals, boots, bushings.

- Medical: Silicone valves, seals, custom enclosures.

- Industrial: Vibration isolators, machine feet, diaphragms.

- Consumer: Wearable bands, keypads, appliance seals.

- Electronics: Cable gaskets, protective boots, switch covers.

How to Choose the Right Rubber Molding Material?

When selecting a rubber compound for your project, consider:

Operating Environment: Will it be exposed to chemicals, oils, extreme temperatures, or UV light?

Mechanical Requirements: Does it need to be soft or stiff, elastic or abrasion-resistant?

Regulatory Compliance: Does the part need FDA, RoHS, or UL certifications?

Cost & Volume: Higher-end materials suit critical applications, while more affordable options work well in bulk.

Design Complexity: Some rubbers flow better in molds, which is crucial for intricate parts.

Conclusion

Understanding the rubber molding process helps you make better design and sourcing decisions. Whether you need durable molded rubber seals or high-precision silicone components, choosing the right molding method and material is key to performance and cost-efficiency.

If you’re looking for a reliable rubber molded parts manufacturer, or not sure how rubber is moulded for your application, our team is here to help.

Get Free Advice from Jiangzhi

Partnering for Profit: Your Winning Solution in Plastic and Rubber OEM