Have you ever wondered about the most common rubber parts defects and how they could impact your projects? During the rubber molding process, various defects can arise, affecting product quality and performance. Many of these rubber part defects are similar to injection molding defects, including issues like warping, short shots, flash, or surface imperfections. Understanding these potential challenges can be crucial in optimizing your manufacturing process and ensuring high-quality outcomes.

What is the Rubber Molding Process?

Before we begin looking at some of the main rubber molding defects and remedies, it’s worthwhile to consider how the rubber molding process works.

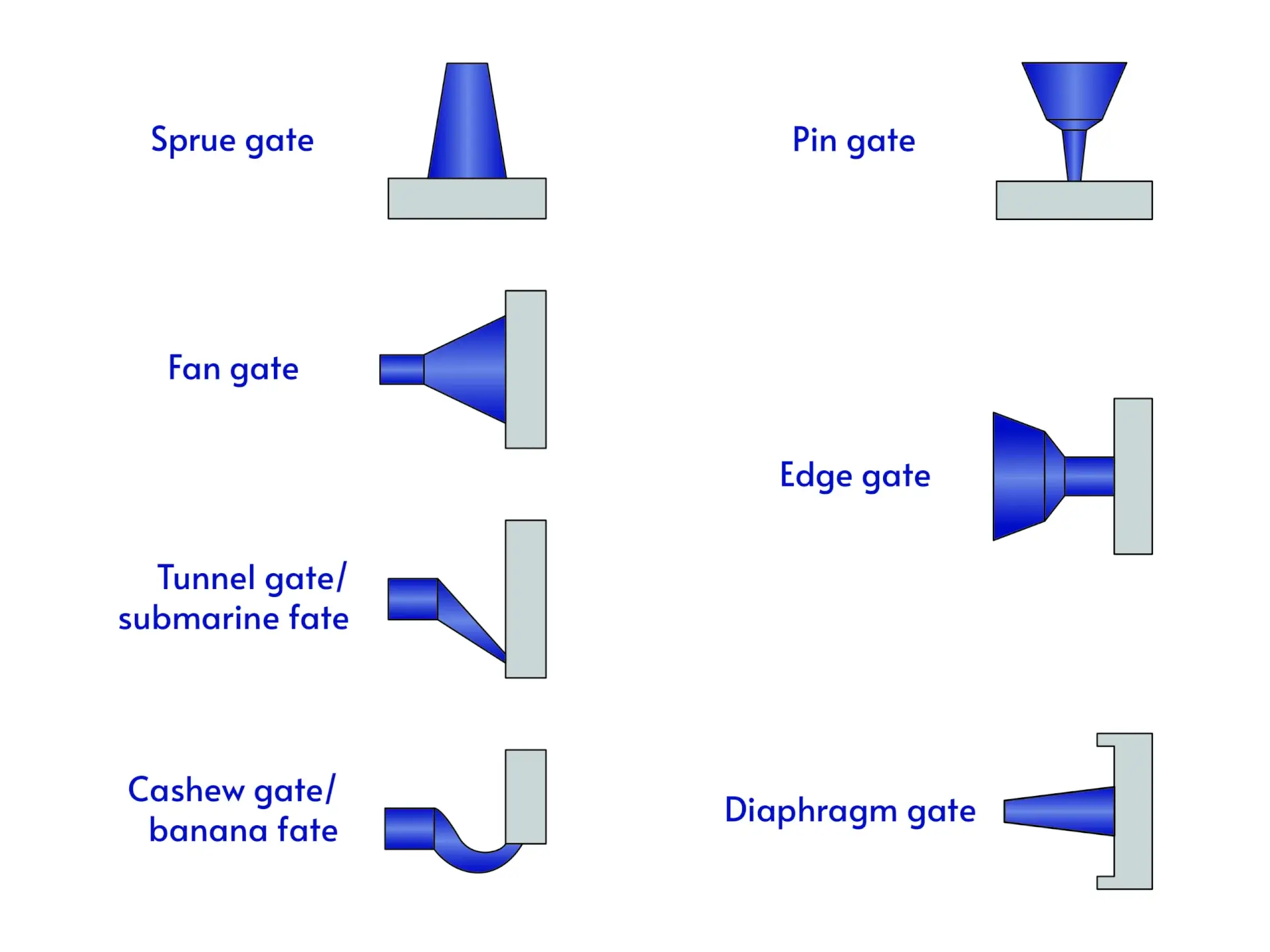

There are three main rubber molding processes:

- Injection Molding

- Transfer Molding

- Compression Molding

Each method varies in technique, cost, and the types of parts it’s best suited for. Among them, compression molding is often praised for its simplicity and efficiency. That’s why many leading manufacturers—like Jiangzhi Rubber and Plastic—utilize this process to deliver consistent, high-quality rubber components for various industries.

Common Rubber Parts Defects

In any of the aforementioned rubber molding processes, defects can arise in the final product, including those specific to rubber compression molding defects. These issues can make your rubber parts more difficult to work with or, in some cases, render them entirely unusable.

Some of the most common rubber moulding defects you might experience include the following points.

Shrinkage

In some scenarios, rubber parts can shrink after they have been removed from the mold. This may be because the mold cavity itself is too small for the final size of the part; as a result, it’s possible for the product to either shrink after being removed or otherwise be an unsuitable size.

Warping

In many scenarios, warping can occur when the rubber part doesn’t cool as intended, resulting from improper molding conditions. Warpage may mean that the final part is defective, and this will usually make most parts defective.

Brittle Materials

If you notice that your rubber parts seem to be brittle after the molding process, this could potentially increase the risk of further defects arising down the line, too. Brittle rubber parts are incredibly likely to crack, and in some cases, they could break completely, certainly not living up to the elasticity expectations of typical rubber parts.

Excess Material

Rubber Molding Defects: Excess Rubber In some cases, weaknesses in the molds can cause excess material and shape deformities in your rubber parts. Though this can often be fixed simply by trimming off the excess, it’s nevertheless a frustrating scenario to find yourself in, especially if this seems to continue happening.

Contaminants

In some cases, if the materials used during the rubber molding process are not completely pure, contaminants could be used in the rubber part. Contaminants can be a significant issue in many cases, since they may compromise the strength of your rubber parts overall. In line with this, partnering with a professional team that uses suitable quality control and contaminant prevention strategies is integral.

rubber defects Contaminants Under certain circumstances, contamination may not be a major problem – for example, this could cause slight discoloration of the final rubber part. However, contaminants could severely hinder the part’s suitability in many cases, especially if found in significant quantities in the final product.

Porosity

In a handful of cases, porosity can become a notable issue with your rubber parts. Porous rubber parts will allow water to pass through in significant quantities or just a little. Nevertheless, this can represent a significant issue, especially if the rubber part is being used to seal a system where water could cause problems overall.

Underfilled Molds

rubber defects NonFills Underfilled molds are one of the most common causes of rubber parts defects that you should be aware of. When a mold is underfilled, key parts may be missed – for example, an important part of a design. This can make a significant difference when it comes to your ability to use the tool, as it may be dysfunctional.

How to Resolve Rubber Molding Defects?

Rubber molding defects are common challenges in the manufacturing of rubber parts. Identifying the causes and implementing corrective measures can ensure consistent, high-quality production. When choosing a rubber parts manufacturer, make sure they apply rigorous quality control at every stage to minimize defects.

1. Ensure Proper Mold Filling

Improperly filled molds are one of the most frequent causes of rubber molding defects. To address this:

- Adjust the shot size to ensure the mold cavities are fully filled.

- Carefully monitor the filling process for uniform distribution of rubber.

- Ensure no air pockets or incomplete areas remain before curing.

Proper mold filling reduces shrinkage, warping, and other common defects.

2. Increase System Pressure

Shrinkage is a major issue in rubber molding, but increasing cavity pressure can often resolve it.

Tips:

- Gradually increase pressure while monitoring part quality.

- Confirm that the pressure increase does not exceed the machine’s safety limits.

- Higher pressure ensures better mold filling and reduces voids in the parts.

3. Extend Cycle Time

Short cycle times can cause warpage, incomplete curing, or dimensional inconsistencies.

- Increasing the cycle time allows the rubber to flow and cure properly.

- Longer cycles can improve part stability and reduce defects caused by uneven cooling.

4. Use Larger Mold Cavities

Shrinkage can make parts smaller than intended. Using slightly larger molds compensates for this.

- Ensure the mold cavity accounts for material shrinkage.

- A professional manufacturer calculates mold size carefully to produce accurate final dimensions.

5. Adjust Temperatures

Incorrect temperature settings in the molding system significantly affect part quality.

- Low mold temperatures: Can produce brittle or under-cured parts.

- High or uneven temperatures: May lead to warping or surface defects.

- Adjust mold and material temperatures to optimize flow and curing characteristics.

6. Seek Professional Support

If defects persist, it may indicate a deeper process or equipment issue.

- Consult experienced rubber parts manufacturers for guidance.

- Professional teams can analyze production processes, recommend adjustments, and ensure consistent quality.

- Choosing the right manufacturer can prevent recurring issues and improve efficiency.

For a more in-depth look at rubber molding defect solutions, refer to this rubber molding defects troubleshooting guide by Zhongren.

Why Work with a Professional Rubber Parts Manufacturer?

If you frequently face rubber defects, it may be time to re-evaluate your supplier or internal processes. At Jiangzhi Rubber and Plastic, we:

- Use precision compression molds built to tight tolerances

- Perform rigorous quality checks at every stage of production

- Customize solutions based on your specific part design and material needs

Final Thoughts: Rubber Molded Parts

Understanding the most common rubber molding defects—and how to effectively resolve them—is essential for any business aiming to improve manufacturing efficiency and product quality. While these defects can often cause significant delays or increased costs, they don’t have to stand in the way of your production goals.

That’s why we’ve put together a practical overview of the most frequent rubber molding issues and their remedies. With the right insights, many of these problems are easier to fix than you might think. By addressing defects early, you can minimize waste, reduce product rejections, and ensure reliable performance—whether you’re producing seals, grommets, or custom industrial components. In short, proactive defect management can make a real difference in your bottom line.