Nylon Injection Molding

PA injection molding achieve lightweight, durable components with 20-40% cost savings over metal. From Jiangzhi get custom nylon molding solutions with fast turnaround.

What is Nylon Injection Molding?

Nylon injection molding is a process where nylon (PA) pellets are melted at high temperatures, injected into a mold, and rapidly cooled to form complex, high-precision parts for mass production. Key benefits:

- High material efficiency, minimal waste.

- Ideal for thin-walled and intricate designs.

- Compatible with PA6, PA66, PA12, and other nylon variants.

Leveraging expertise in hygroscopic material handling, gate design optimization, and crystallization control, we provide scalable solutions for complex geometries and high-stress environments. From prototypes to high-volume production, our ISO-certified processes meet stringent industry demands for nylon parts.

Injection Molding Nylon Parameters Table

| Parameter | Recommended Range |

|---|---|

| Wall Thickness | 0.8mm - 3.5 mm |

| Maximum Part Size | 2000mm x 1500mm x 1000mm |

| Minimum Feature Size | 0.4mm-0.8mm |

| Tolerances | ±0.05mm - ±0.3mm |

Common Nylon Materials & Properties

Nylon (Polyamide) is a versatile engineering thermoplastic renowned for its exceptional strength-to-weight ratio, heat resistance, and wear performance. As a semi-crystalline polymer, it dominates demanding plastic injection molding applications through its unique molecular structure and customizable formulations. Performance is often enhanced through the following ways:

- Glass Fiber Reinforcement: Increases tensile strength by 50%-150% (e.g., PA6-GF30 achieves 180 MPa vs. 80 MPa for pure PA6).

- Heat Stabilizers: Elevate continuous service temperature to 180°C+ (critical for under-hood automotive components).

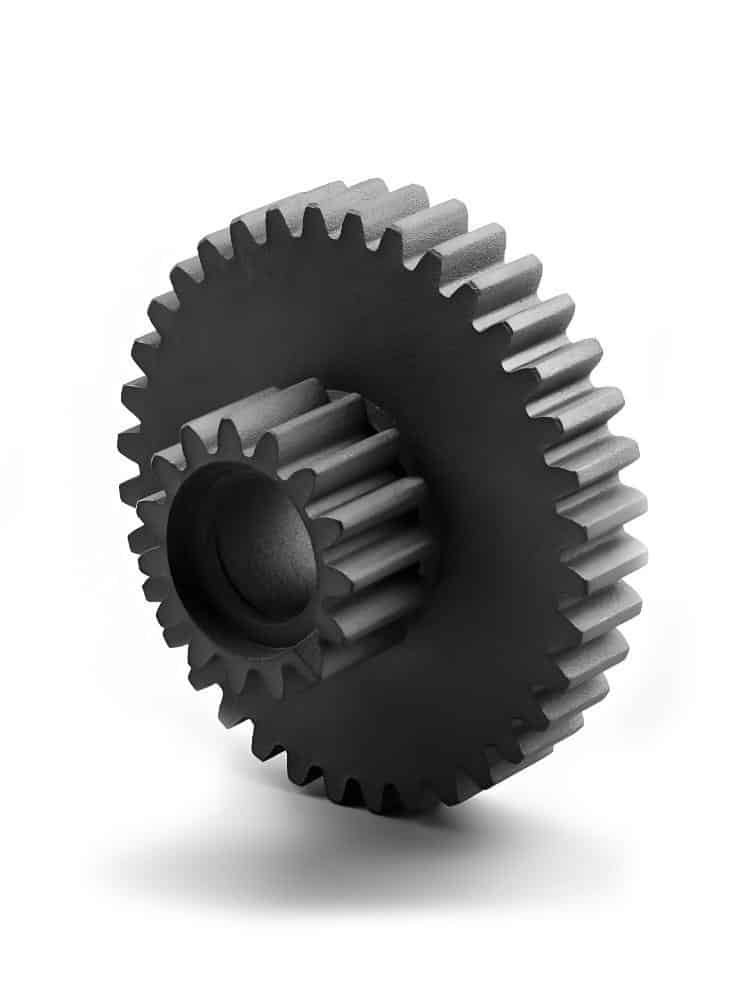

- Lubricant Additives: Reduce friction coefficients by 40%, ideal for gears and sliding parts.

| Property | Density | Tensile Strength | Flexural Strength | Impact Strength (Unnotched) | Heat Deflection Temp (0.45 MPa) |

|---|---|---|---|---|---|

| PA6 | 1.12 - 1.15 g/cm³ | 70 - 90 MPa | 100 - 120 MPa | 50 - 100 kJ/m² | 180 - 200℃ |

| PA66 | 1.12 - 1.15 g/cm³ | 80 - 95 MPa | 110 - 140 MPa | 60 - 120 kJ/m² | 190 – 210°C |

| PA12 | 1.01 - 1.02 g/cm³ | 45 - 55 MPa | 40 - 50 MPa | 120 – 200 kJ/m² | 140 – 160°C |

- The above parameters represent the baseline performance of the materials. Actual application should be dynamically optimized based on specific working conditions.

Need Reliable Nylon Injection Molding?

Strong, Wear-Resistant Nylon Injection Molding – Custom Solutions for Your Needs.

Advantages & Disadvantages of Nylon Injection Molding

Nylon plastic injection molding delivers superior strength, wear resistance, and chemical stability, making it ideal for demanding automotive, electronics, and industrial components. While offering distinct advantages, the process requires careful consideration of material behaviors like moisture absorption and thermal expansion.

Advantages

- High Strength & Lightweight: 50% lighter than metal

- Chemical Resistance: Resists oils, fuels, and weak acids/bases

- Fast Production: Durable molds support high-volume orders

Disadvantages

- Moisture absorption: Requires pre-drying to prevent defects

- Higher shrinkage: Demands precise mold design

Applications of Injection Molded Nylon

Injection molded nylon, renowned for its strength, durability, and heat resistance. Its capabilities produce lightweight, cost-effective components that often replace metals. Enhanced by reinforced and recycled variants, nylon also supports sustainable manufacturing, solidifying its role as a critical material in modern engineering solutions.

Automotive Industry

- Engine covers

- Fuel system components

- Nylon gears

- Plastic bushings

- Radiator end tanks

Electronics Industry

- Connectors

- Switch housings

- Circuit breaker components

- Insulating casings

- Battery cover/seal ring

Mechanical Equipment

- Gears

- Bearings

- Rollers

- Conveyor system components

- Machine housings

Medical Devices

- Surgical instrument handles

- Prosthetic components

- Medical tubing

- Breathing mask/connector

- Artificial joint pad

Jiangzhi PA Injection Molding Parts are Guaranteed