Plastic Material

Plastic Material Overview

Plastic material is a material composed of synthetic polymers and is widely used in various industries. Depending on the chemical composition and production process, plastics can be divided into many types, such as:

- Thermoplastics: This type of plastic becomes soft when heated, solidifies when cooled, and can be heated and molded multiple times. For example: polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS) and so on.

- Thermosetting plastics: This type of plastic will undergo a chemical reaction during heating and cannot be softened again after curing. For example: epoxy resin, phenolic resin, polyurethane (PU) and so on.

- Elastomer: has excellent elasticity and recovery, such as natural rubber, silicone rubber, neoprene and so on.

Plastic materials are widely used in packaging, electronics, electrical appliances, automobiles, construction and other fields because of their portability, corrosion resistance, easy processing and low cost.

Navigating through numerous plastic resins can be overwhelming. Each resin possesses distinct properties and processing needs. Additionally, various grades exist, incorporating fillers like glass or carbon fibers, along with specific brand variations.

The extensive array of options makes selecting the ideal material for your project challenging. Whether you’re delving into medical plastic injection molding, creating molded components for the automotive sector, or tackling another venture, Jiangzhi experts stand prepared to guide you swiftly from design to production.

Following are some of common plastic types we offer

Plastic Heat Resistance Chart

| Material | Max Service Temperature (°C / °F) | Max Service Temperature (°C / °F) |

|---|---|---|

| Polyethylene (PE) | 80°C / 176°F | Lightweight, chemical resistant, low cost |

| Polypropylene (PP) | 120°C / 248°F | Excellent fatigue resistance, low density |

| Polystyrene (PS) | 70°C / 158°F | Brittle, economical |

| Polyvinyl Chloride (PVC) | 60°C / 140°F (Rigid) | Good weathering resistance |

| Acrylonitrile Butadiene Styrene (ABS) | 100°C / 212°F | Durable, impact resistant |

| Polycarbonate (PC) | 130°C / 266°F | Transparent, high impact strength |

| Nylon (Polyamide, PA) | 180°C / 356°F | Wear-resistant, high mechanical strength |

| Polyethylene Terephthalate (PET) | 115°C / 239°F | Good dimensional stability, clear |

| Polysulfone (PSU) | 180°C / 356°F | High heat resistance, transparent |

| Polyphenylene Sulfide (PPS) | 220°C / 428°F | Excellent chemical and thermal resistance |

| Polyetherimide (PEI) | 217°C / 423°F | Excellent strength, flame retardant |

| Polyetheretherketone (PEEK) | 250°C / 482°F | Superior mechanical and thermal properties |

| Polytetrafluoroethylene (PTFE) | 260°C / 500°F | Exceptional chemical and heat resistance |

Notes:

- Max Service Temperature is approximate and depends on specific grades and formulations.

- Actual performance can vary with factors like load, time, and exposure conditions (e.g., continuous vs. intermittent heat).

- Additives can enhance heat resistance for specific applications.

Advantages of Plastic Material in Manufacturing

Lightweight

Durability

Corrosion Resistant

Insulating Properties

Material Modification

Jiangzhi Plastic Processing Service

Large Part Injection Moding

Plastic Parts in Different Industries

Popular Post

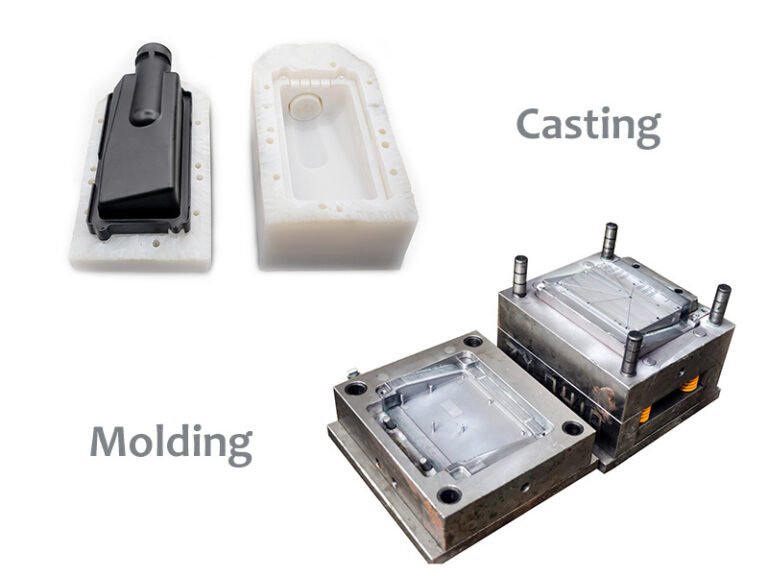

What is the Difference Between Casting and Molding?

In the world of manufacturing understanding the difference between casting and molding is crucial for selecting the right process for

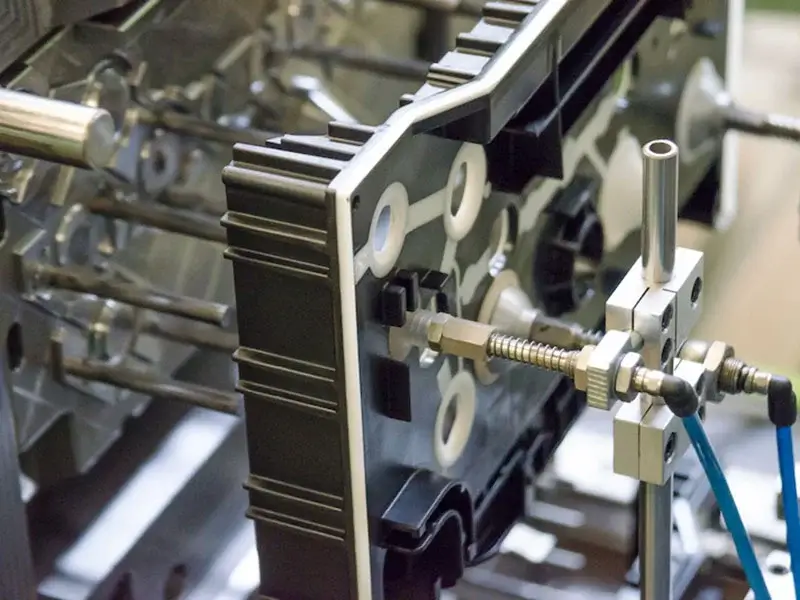

What’ s Gas Assisted Injection Molding?

Gas assisted injection molding is revolutionizing the manufacturing landscape by offering a smarter more efficient way to produce complex plastic

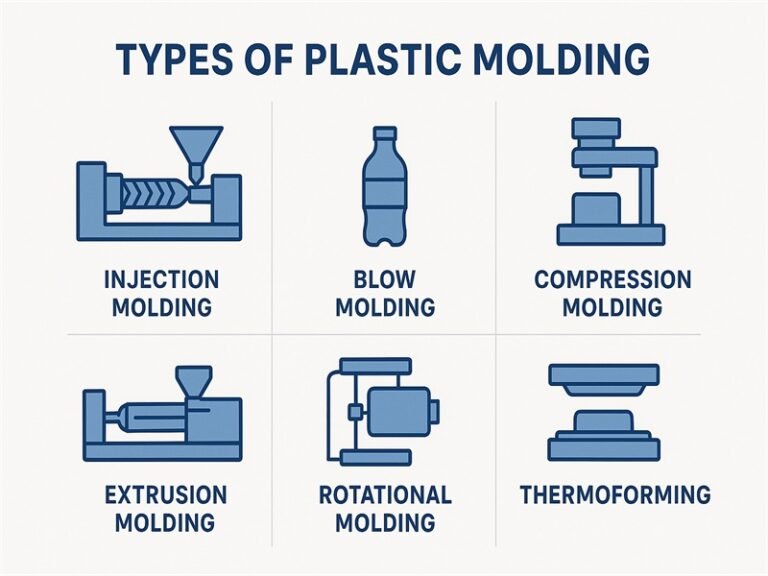

Six Plastic Molding Types: A Detailed Overview

Understanding the various plastic molding types is essential for choosing the right manufacturing process for any plastic product From high