Rubber Material

Rubber Material Overview

Information Optimization: A Comprehensive Introduction to Rubber Materials

Rubber Material is a material with high elasticity and plasticity, which is widely used in industrial and consumer products. According to the source, rubber can be divided into natural rubber (NR) and synthetic rubber two categories:

Natural rubber (NR) : Made from latex extracted from rubber trees, it has excellent elasticity, wear resistance and tear resistance.

Synthetic rubber: prepared by chemical synthesis methods, including many types, such as:

- Styrene butadiene rubber (SBR) : Commonly used in tires and industrial products.

- Neoprene rubber (CR) : Because of its excellent oil resistance and weather resistance, it is widely used in waterproof materials and seals.

- Silicone rubber (SI) : known for high and low temperature resistance, suitable for medical and aviation fields.

At Jiangzhi, we prioritize delivering top-notch products by thoroughly understanding your application needs. Our in-depth analysis enables us to offer personalized recommendations for the most effective rubber material. Additionally, we can process base polymers to customer specifications, ensuring a tailored approach to meet your unique requirements.

Learn more:select rubber material guide

Following are some of the common rubber types we offer

Rubber Materials Industry Application : Requirements of Multiple Industries

With its excellent elasticity, wear resistance, weather resistance and insulation properties, rubber plays a vital role in modern industry and daily life. From automotive tires and seals to shock-proof materials for industrial equipment to medical devices and household items, rubber meets the needs of many fields with its versatility. With the development of science and technology, the application of rubber materials in the direction of environmental protection and high performance is also constantly expanding, providing more innovative and sustainable solutions for various industries

Automobile industry

- Tires: Different formulations of rubber materials in the body and tread for high wear resistance and skid resistance.

- Seals: such as window seals, engine gaskets, provide dust-proof, waterproof effect.

- Damping Elements: Rubber shock absorbers in the suspension system reduce vibration and noise.

Industrial manufacturing

- Conveyor Belt: wear-resistant and high-temperature rubber is widely used in mining, metallurgy and other industries.

- Anti-corrosion Coating: Used in chemical containers and pipelines, outstanding chemical corrosion resistance.

- Shockproof Device: used as a buffer and protection material in industrial equipment.

Healthcare and consumer goods

- Medical Equipment: such as latex gloves, catheters to meet flexibility and hygiene requirements.

- Household Goods: floor MATS, soles, rubber bands and other products, rubber is favored for its elasticity and durability.

Processing Technology and Method: the Core Link from Design to Manufacturing

Mixing technology

The first step of rubber processing is to evenly mix the rubber matrix with fillers (such as carbon black), vulcanizing agents and other additives to optimize the performance of the final product.

Vulcanization technique

Vulcanization is done by adding sulfur or other crosslinking agents to form a three-dimensional network structure of rubber to improve its hardness, strength and durability.

- High temperature vulcanization (HTV) : used in tire manufacturing.

- Room temperature curing (RTV) : Suitable for small industrial components.

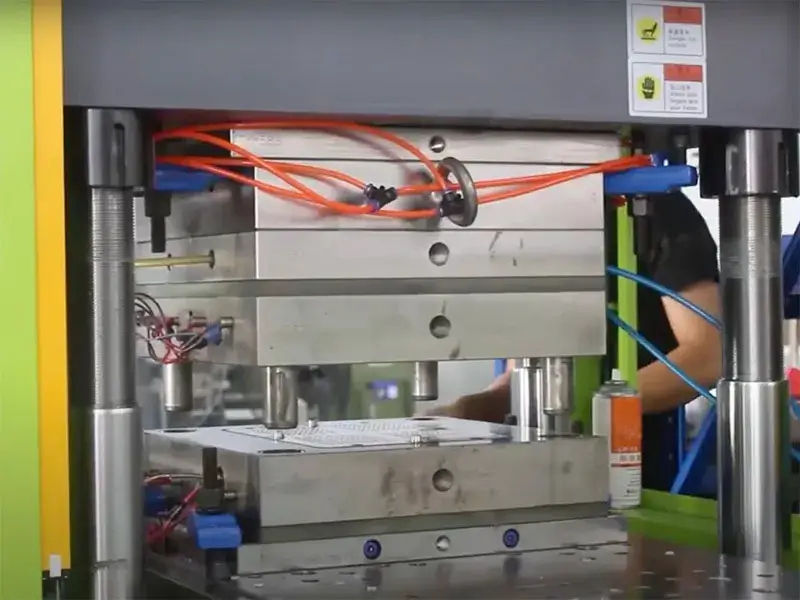

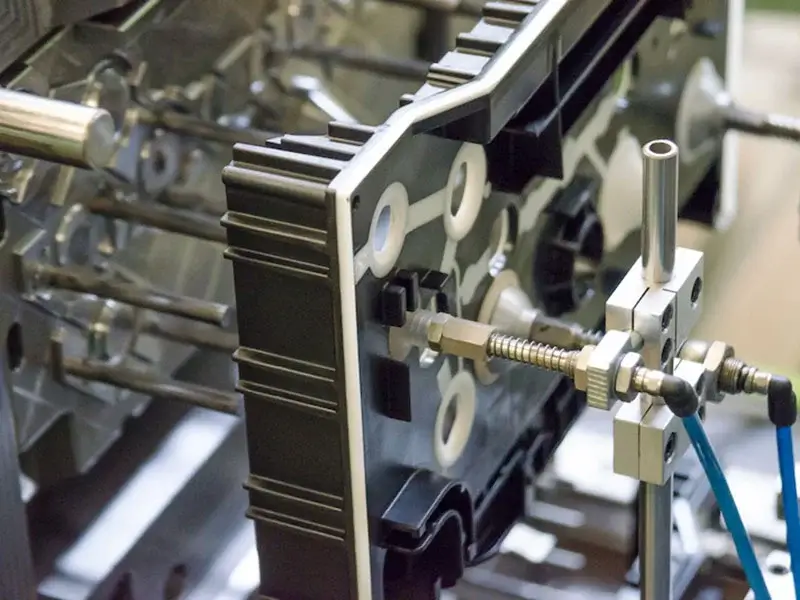

Rubber injection molding:

- Compression molding service: Rubber is heated and pressurized in a mold for the production of complex structural parts.

- Injection molding service: Suitable for mass production of small rubber parts, high efficiency.

Material Modification

Jiangzhi Rubber Processing Service

Advantages of Rubber Material in Manufacturing

Resilience

Sealing Properties

Chemical Resistance

Noise and Vibration Damping

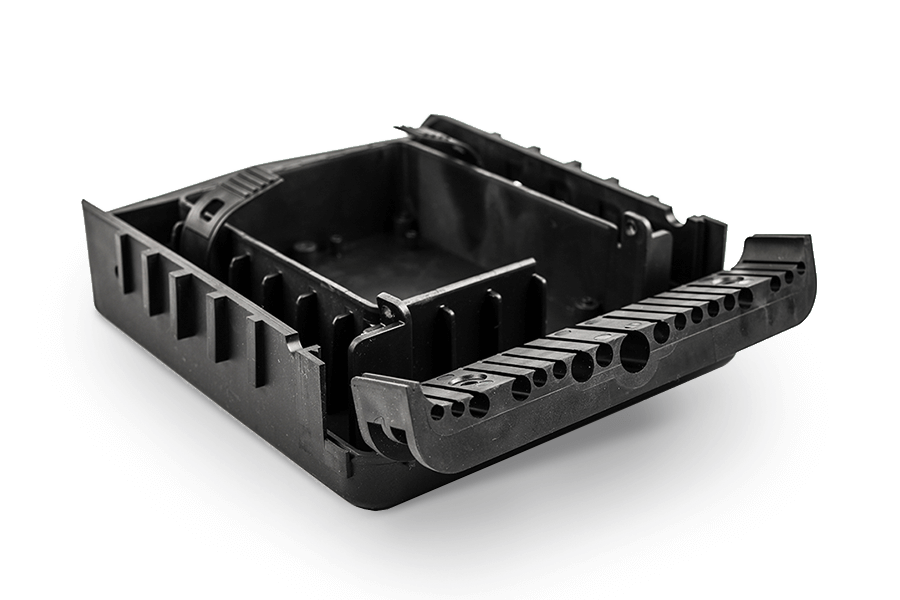

Rubber Part in Different Industries

Popular Post

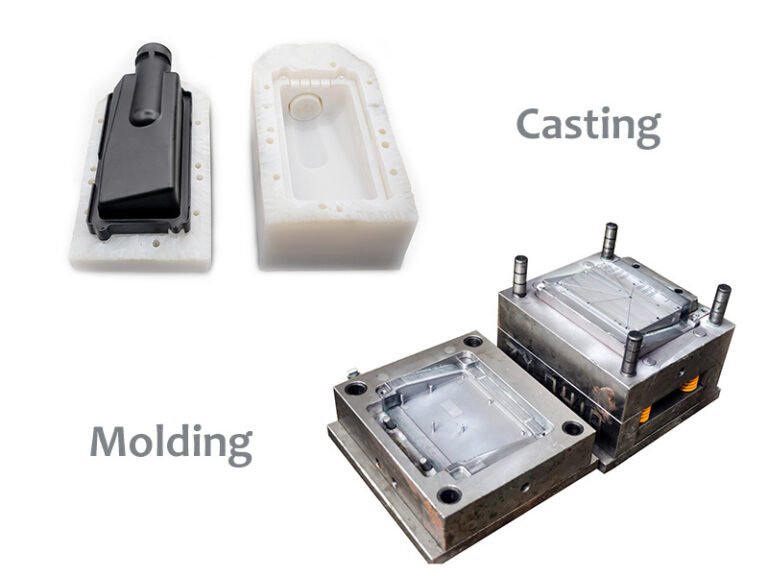

What is the Difference Between Casting and Molding?

In the world of manufacturing understanding the difference between casting and molding is crucial for selecting the right process for

What’ s Gas Assisted Injection Molding?

Gas assisted injection molding is revolutionizing the manufacturing landscape by offering a smarter more efficient way to produce complex plastic

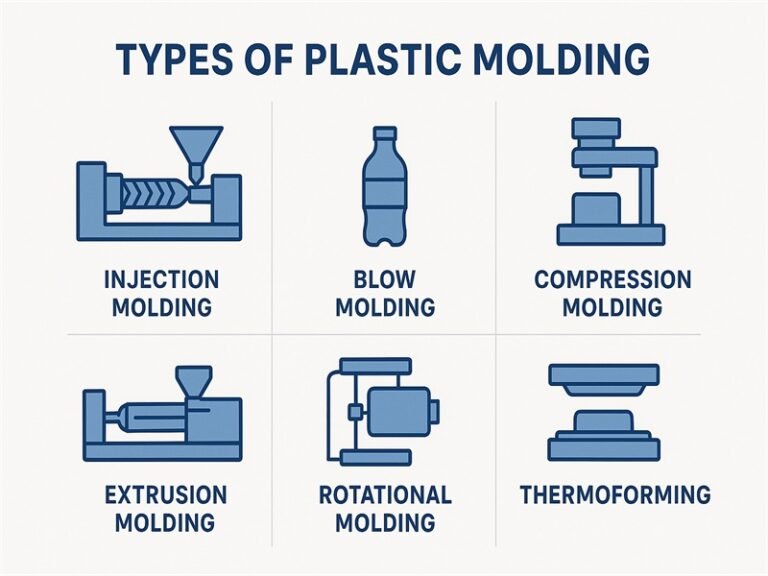

Six Plastic Molding Types: A Detailed Overview

Understanding the various plastic molding types is essential for choosing the right manufacturing process for any plastic product From high