TPE Injection Molding Material

Thermoplastic-Elastomers Overview

Thermoplastic elastomers (TPEs) are a family of versatile polymers that exhibit both rubber-like elasticity and thermoplastic processability. With a unique blend of flexibility, chemical resistance, and weather resistance, TPEs find extensive use in various industries. They can be easily molded and processed, providing manufacturers with a cost-effective solution for applications requiring both elasticity and moldability.

Whether in consumer goods, automotive components, or medical devices, TPEs offer a range of tailored properties, making them a preferred choice for manufacturers seeking adaptable materials for diverse applications.

Here are the resins we supply:

- TPE

- TPU

- TPV

TPE

Thermoplastic Elastomer

- Rubber elasticity

- Workability of plastics

- Environmentally friendly and recyclable

TPU

Thermoplastic Polyurethane

- High strength

- wear-resistant

- Chemical resistance

TPV

Thermoplastic Vulcanizate

- High temperature resistance

- Strong weather resistance

- Long-term durability

Theromoplastic Elastomer Material Property

| Material Type | Hardness | Elasticity | Wear Resistance | Chemical Resistance | High-Temperature Resistance |

|---|---|---|---|---|---|

| TPE | 50-90 Shore A | High | Excellent | Excellent | Excellent |

| TPU | 40-95 Shore A | High | Excellent | Good | Good |

| TPV | 50-90 Shore A | Good | Good | Excellent | Good |

Key Points:

- Hardness: Indicates how hard or soft the material is.

- Elasticity: Refers to flexibility and resilience.

- Wear Resistance: How well the material resists wear and tear.

- Chemical Resistance: Ability to resist chemicals.

- High-Temperature Resistance: How well the material handles high temperatures

- Resistance: How well the material handles high temperatures.

Material Modification

Jiangzhi TPE Processing Service

Advantages of TPE in Manufacturing

Ease of Processing

Thermoplastic Nature

Excellent Flexibility

Overmolding Capability

Rubber Part in Different Industries

Jiangzhi Popular Post

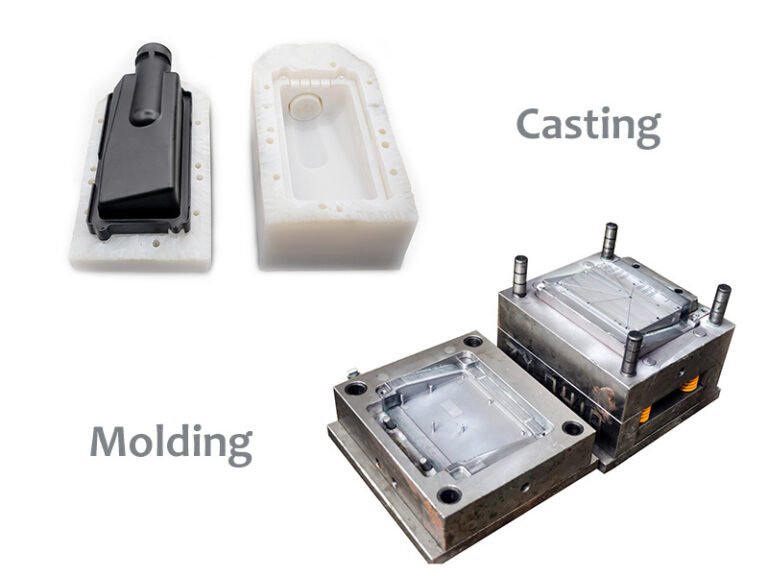

What is the Difference Between Casting and Molding?

In the world of manufacturing understanding the difference between casting and molding is crucial for selecting the right process for

What’ s Gas Assisted Injection Molding?

Gas assisted injection molding is revolutionizing the manufacturing landscape by offering a smarter more efficient way to produce complex plastic

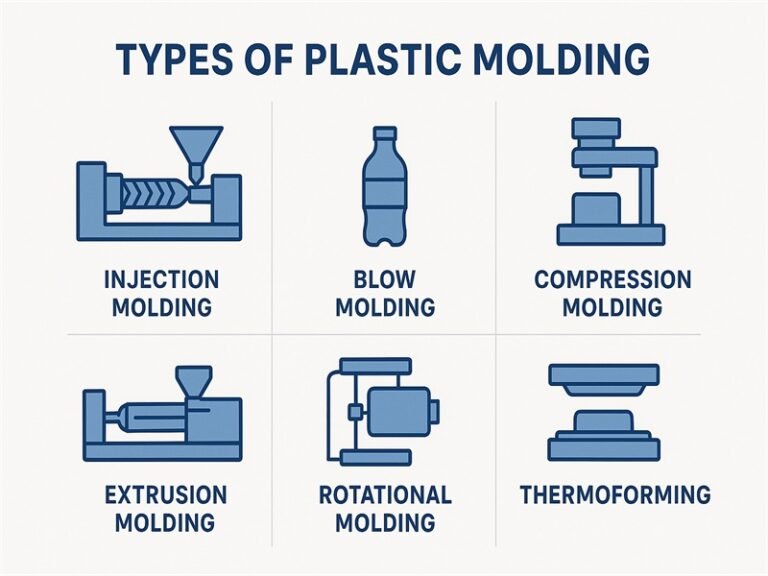

Six Plastic Molding Types: A Detailed Overview

Understanding the various plastic molding types is essential for choosing the right manufacturing process for any plastic product From high