Custom Machining Services

Precision CNC Milling & Turning From Prototypes to High-Volume Production

- CNC Milling & Turning for Metal, Plastic, and Composite Materials

- Tight Tolerances (±0.001") with ISO 9001 Certification

- Fast Turnaround – 3-5 Days Standard Lead Time

- Low MOQ – Start from 1 Piece

Our custom machining services are designed to meet your specific requirements. At Jiangzhi, we offer expert Precision CNC machining services, specializing in CNC turning and CNC milling to create CNC precision parts for a wide range of industries. Whether you need a CNC prototype machining service or high-volume production, we deliver top-quality results tailored to your specifications.

CNC Custom Machining Service Capabilities

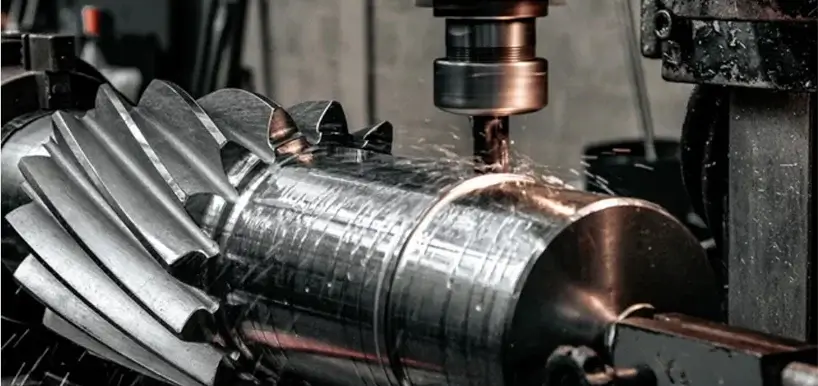

Precision Custom CNC Milling

Multi-axis CNC milling for complex geometries part. Capable of 3D contouring, pocketing, and rapid prototyping processing. Materials: Plastics, Alloys, Engineering Polymers.

Precision Custom CNC Turning

Our CNC turning services produce cylindrical parts with ±0.002mm tolerance. Ideal for shafts, bushings, and custom prototypes. Materials: Aluminum, Stainless Steel, Titanium.

Custom CNC Machining Service Technical Parameters

| Parameter | CNC Milling | CNC Turning |

|---|---|---|

| Precision | ±0.001" | ±0.002" |

| Materials | Aluminum, Steel | Stainless Steel |

| Surface Treatment | Anodizing, Powder Coating | Polishing, Plating |

| Cutting Speed | High speed for fine finishes | Moderate speed for turning |

| Tooling | End mills, face mills, drills | Turning tools, inserts |

| Production Volume | Ideal for medium to large batches | Suitable for small to large batches |

Custom CNC Machining Materials

Plastic Material

Metal Material

- Aluminum

- Brass

- Copper

- Stainless Steel

- Steel Alloy

- Steel Mild Low Carbon

Metal Materials Selection

The choice of metal material in CNC metal machining is crucial as it directly impacts the performance, durability, and cost-effectiveness of the final product. Selecting the right material ensures the CNC machining part can withstand required stress, environmental conditions, and specific functionalities, while also optimizing the machining process for efficiency and precision. With our custom machining services, we help you choose the ideal material that meets the unique demands of your project, ensuring maximum performance and cost-efficiency.

CNC Machining Service Benefit

Compared to manual machining, CNC technology improves efficiency and accuracy, resulting in faster production, safer operations and lower costs.

- CNC machining have little to no waste of material

- High precision and greater accuracy

- Faster and efficient production

- Less dependabilitiy on human labor and fewer human errors

- Reduction in energy consumption

CNC Machining Parts

Many products in our lives come from CNC machining service:

- Gears

- Shafts

- Brackets

- Housings

- Connectors

- Fittings

- Bushings

Machining Parts Manufacturers: Case Show

Custom CNC Machining Parts in Different Industries

CNC custom machining service is used in a variety of industries to create precise, high-quality components. From aerospace parts to automotive components, and medical devices, our custom CNC machining services offer the versatility to produce complex, high-performance parts that meet stringent industry standards. Whether you need prototypes, customized parts, or mass production, CNC machining provides the precision and efficiency your projects demand.

Why Choose Us?

Ensuring accurate and intricate part production

Our commitment to precision ensures the flawless production of intricate parts. With advanced technology and a meticulous approach, we guarantee the utmost accuracy in every detail of your CNC molded components.

Meeting diverse industry needs

Our CNC custom machining services address a range of industries, meeting diverse needs effectively. Whether in medical, consumer, or automotive sectors, our adaptability ensures customized solutions tailored to unique industry requirements.

Proven track record in successful projects

Our extensive track record speaks volumes about our prowess in CNC machining. Successfully completing a range of projects across various industries, we demonstrate a consistent commitment to delivering quality and meeting client expectations.

Rigorous quality checks for reliable results

Our dedication to excellence is reinforced through rigorous quality checks, ensuring consistently reliable results. Every stage of our custom machining services process undergoes meticulous scrutiny, guaranteeing the delivery of top-tier and dependable outcomes.

Professional CNC Machining Process Service Company

Improve production efficiency and choose efficient CNC machining solutions!

FAQs of Custom Machining Services

How long does CNC machining take?

Generally, for 1-10 pieces, delivery takes around 3-5 days, and for 10-500 pieces, it takes 7-20 days.

How do I know if CNC machining is right for my project?

CNC machining is great for projects that need high precision, complex shapes, or tight tolerances. It’s perfect for industries like aerospace, automotive, and medical, where accuracy is critical. If you need quality parts quickly, CNC precision machining can handle both small and medium production runs effectively. Not sure if CNC fits your project? Contact us, and we’ll help you decide the best approach for your needs!

What are the benefits of plastic CNC machining?

How does CNC machining compare to 3D printing?

CNC machining offers high precision and can work with more durable materials, making it better for functional parts. 3D printing is great for rapid prototyping but may not match CNC in terms of material strength or fine detail. Not sure which method to choose? Reach out, and we’ll help you pick the best solution for your project!

What are the best materials for CNC metal machining?

The best metal material for CNC metal machining depends on your project requirements. Commonly used materials include aluminum, stainless steel, brass, and titanium. Each material offers different benefits such as strength, corrosion resistance, and machinability. For example, aluminum is lightweight and easy to machine, while stainless steel offers superior durability and corrosion resistance. Our custom machining services can help you select the optimal material for your project based on factors like strength, environmental conditions, and functionality.

What is the cost of CNC machining?

Costs depend on factors like material, complexity, and quantity. Simple parts cost less, while detailed parts may be more expensive. Larger production runs typically lower the per-unit cost.Want a cost estimate? Send us your design, and we’ll provide a clear, customized quote!