Injection Molding Service: Precision Parts with Expertise

Our injection molding service ensures expertly precision parts. Trust in our commitment to quality and efficiency for all your custom injection molding needs.

Injection Molding Process

Discover our full spectrum of injection molding processes—tailored to deliver accuracy, repeatability, and cost efficiency across various industries. As a professional injection molding company, we specialize in everything from overmolding and insert molding to multi-shot solutions. Each method is carefully engineered to meet your specific material needs and design goals.

Plastic Injection Molding

Rubber Injection Molding

Overmolding & Insert Molding

Injection Molding Service From Rapid Prototyping to Production

Rapid Prototyping

Benefit from our rapid prototyping expertise, ensuring swift and precise creation of prototypes. We expedite the product development process, offering a quick and efficient path from concept to tangible model.

- Accelerated Time-to-Market

- Cost-Efficient Development

- Comprehensive Material Options

On-demand Manufacturing

Experience the flexibility of on-demand manufacturing with us. Tailor production to your exact needs, minimizing excess inventory and costs. Efficiently meet changing demands with precision and a streamlined process.

- Dedicated Project Manager

- Consistent Quality Guaranteed

- Optimized Cost Structure

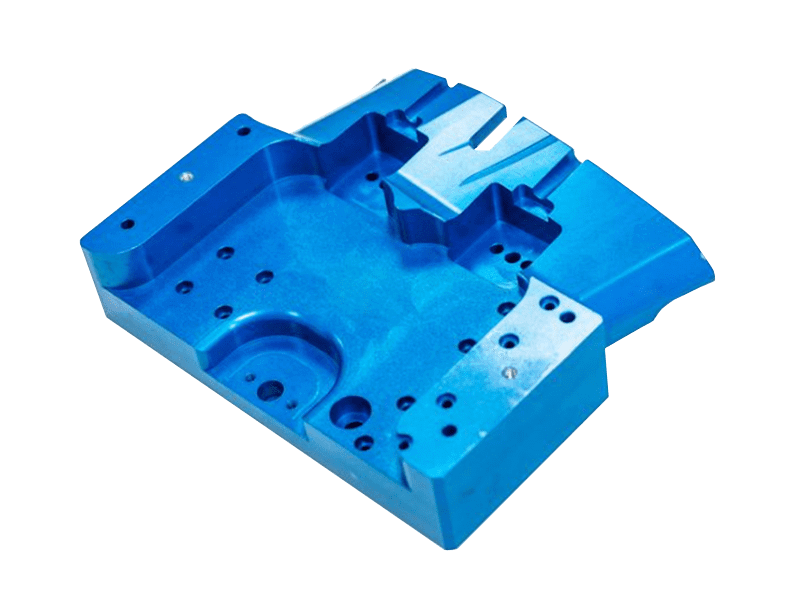

Injection Mold Tooling Options

Compare our Injection Mold Tooling Options, showcasing our expertise in both prototyping and on-demand manufacturing. We ensure a seamless transition from rapid prototyping to cost-effective on-demand production, guaranteeing precision and efficiency at every project stage.

| Prototyping | On-Demand Manufacturing | |

|---|---|---|

| Objective | I demand swift design validation with Jiangzhi's efficiency. I seek the flexibility for economical iterations before transitioning into on-demand manufacturing. | I have on-demand prodction requirement that need that require consistent high quality parts. |

| Mold Cavities | Single | Single or multi-cavity |

| Mold Life | Limited (guaranteed for at least 2,000 shots) | Unlimited |

| Mold Storage | Store for 24 months | Forever |

| Mold Material | Aluminum | P20 Steel |

Injection Molding Materials

Discover a variety of options in our custom Injection Molding Material selection, featuring over 50 stocked types. We provide quality and efficiency to meet your project's specific needs.

Rubber Material

- Silicone

- EPDM (Ethylene Propylene Diene Monomer)

- Nitrile (NBR)

- Neoprene (CR)

- SBR (Styrene Butadiene Rubber)

- Natural Rubber (NR)

- Butyl Rubber (IIR)

- Viton (FKM)

Injection Molding Service Surface Finishing

| Finish | Description |

|---|---|

| SPI A1 | 6000 grit diamond, surper high glossy finish |

| SPI A2 | 3000 grit diamond, high glossy finish |

| SPI A3 | 1200 grit diamond, normal glossy finish |

| SPI B1 | 600 grit paper, fine semi-glossy finish |

| SPI B2 | 400 grit paper, normal semi-glossy finish |

| SPI B3 | 320 grit paper, normal semi- |

| SPI C1 | 600 grit stone, fine matte finish |

| SPI C2 | 400 grit stone, medium matte finish |

| SPI C3 | 320 grit stone, normal matte finish |

| SPI D1 | Dry blast glass bead, satin textured finish |

| SPI D2 | Dry blast, dull textured finish |

| SPI D3 | Dry blast, rough textured finish |

How Does Injection Molding Process Work?

Injection molding service is a precise and versatile manufacturing process that transforms raw materials, typically plastic or rubber pellets, into intricate and custom-designed components. The process involves the following key steps:

Material Melting

Raw material is fed into the injection moulding machine in the form of small pellets. These pellets are then heated to a molten state within the machine.

Injection

Cooling

Ejection

Cycling

Injection Molding Material Selection Guide

Choosing the right material for injection molding is critical to the success of any manufacturing project. The material impacts the product’s durability, performance, aesthetics, and cost. This comprehensive guide will help you navigate the complex process of material selection for injection moulding, ensuring your products meet all necessary requirements.

Advantages of Injection Molding Parts

From intricate designs to high-volume production, Injection Molding stands out with its precision, efficiency, and adaptability.

- Low production lost with efficient high-volume manufacturing

- Available for a wide range of materials

- Manufacture components with intricate shapes and complex geometries

- Ensure repeatability of production and consistency of quality

- Enhance aesthetics with a variety of surface finish treatments

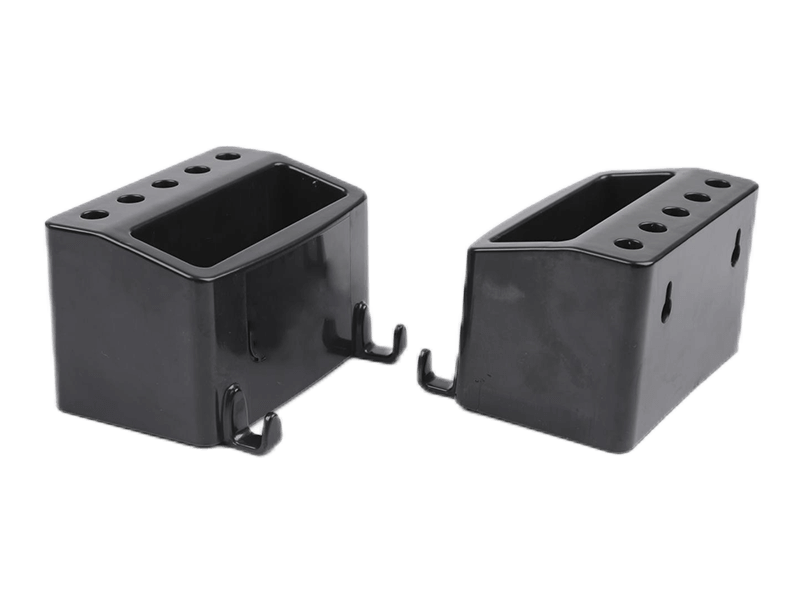

Custom Injection Molding Application

Injection molding finds extensive use in producing plastic parts for medical, consumer, and automotive industries. Commonly manufactured parts include:

- Enclosure

- Pulley

- Gear

- Clip

- Electronic connectors

- Handle

- Bumper

Precision Custom Injection Molding Fundamental

Need Perfect Injection molding Parts? Discover How Precision Plastic Molding Delivers Unmatched Quality and Accuracy? Maximize Efficiency and Minimize Waste.

What is injection molding service?

Injection molding is a manufacturing process used to produce parts by injecting molten material into a mold under pressure. The material solidifies to form a part.

Keywords: injection molding process, injection molding definition, plastic injection molding, molding machine, molding cycle

What are the benefits of injection moulding services?

Custom injection molding service offers high precision, quick production cycles, and the ability to produce complex shapes in large quantities with minimal waste.

Keywords: high efficiency, mass production, precision molding, cost-effective manufacturing, molding advantages

What materials can be used in injection molding?

Custom Injection molding typically uses thermoplastics, thermosets, elastomers, and composites, with thermoplastic polymers being the most common.

What is the typical injection molding cycle time?

The cycle time can range from 10 to 30 seconds for small parts, but it depends on the material, mold complexity, and part size.

Keywords: injection molding cycle, cycle time, production speed, fast molding, molding time efficiency

What are common defects in injection molding and how can they be avoided?

Common defects include warping, sink marks, air traps, flash, and short shots. Proper mold design, temperature control, and material selection can help prevent these issues.

Keywords: injection molding defects, warping, sink marks, air traps, flash, mold design, defect prevention

How long does an injection mold last?

The lifespan of an injection mold depends on factors like material hardness, production volume, and maintenance. Typically, it can last anywhere from 100,000 to 1 million cycles.

Keywords: mold lifespan, mold durability, injection mold maintenance, mold wear, mold cycle count

How do injection molding costs down?

Injection molding costs are typically broken down into material costs, mold costs, labor, and machine operation costs. Mold costs are often the most significant upfront expense.

Keywords: molding costs, cost breakdown, injection molding pricing, mold expenses, cost-effective molding

What is the importance of mold design in injection moulding?

Proper mold design is crucial to ensure that the mold can withstand the pressures of injection molding, provide consistent part quality, and avoid defects.

Keywords: mold design, mold engineering, injection mold design, mold cavity design, injection molding tools

How does injection molding compare to other manufacturing methods?

Compared to methods like CNC machining or 3D printing, injection molding offers faster production speeds, higher precision for high-volume runs, and lower unit costs over time.

Keywords: injection molding vs machining, injection molding vs 3D printing, manufacturing methods comparison, cost comparison

Why Choose Us Custom Injection Molding Service?

Comprehensive Injection Molding Solutions

We offer a full range of injection molding services, from custom injection moulding to prototype molding and high-volume production. Whether you need plastic molding, overmolding, or insert molding, our advanced manufacturing capabilities ensure precision, durability, and cost-effectiveness.

Advanced Manufacturing Technology & Materials

End-to-End: From Design to Final Product

We provide comprehensive support, including DFM (Design for Manufacturability) analysis, mold making, and post-processing services like surface finishing, assembly, and packaging. Our expert team ensures seamless execution from concept to final product delivery.

Cost-Effective & Scalable Production

Professional Injection Molding One-Stop Service Company

FAQs of Custom Injection Molding

What industries use injection molding?

custom Injection moulding service is widely used in automotive, medical, consumer goods, electronics, and aerospace industries for producing various components.

What is the typical lead time for injection molding projects?

Lead times vary but are generally influenced by factors such as part complexity, quantity, material selection, and mold design. In general, Jiangzhi lead time is 3-4 weeks for mold, 2-4 weeks for mass production.

How can I optimize my design for injection molding?

Design considerations include uniform wall thickness, proper gating and venting, draft angles, and material selection to ensure successful and efficient injection molding.

Can injection molding be used for prototyping?

Yes, injection molding can be used for prototyping using rapid tooling or soft tooling methods to create low-volume prototypes.