Overmolding and Insert Molding Service

Overmolding vs. Insert Molding

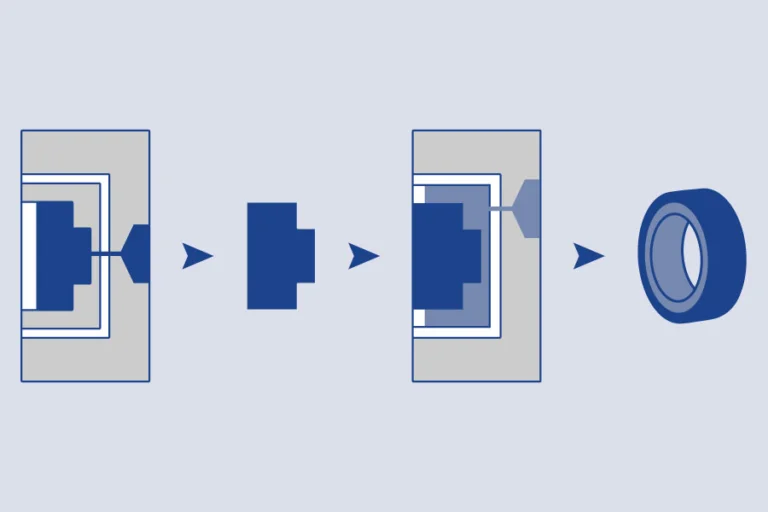

What is Overmolding

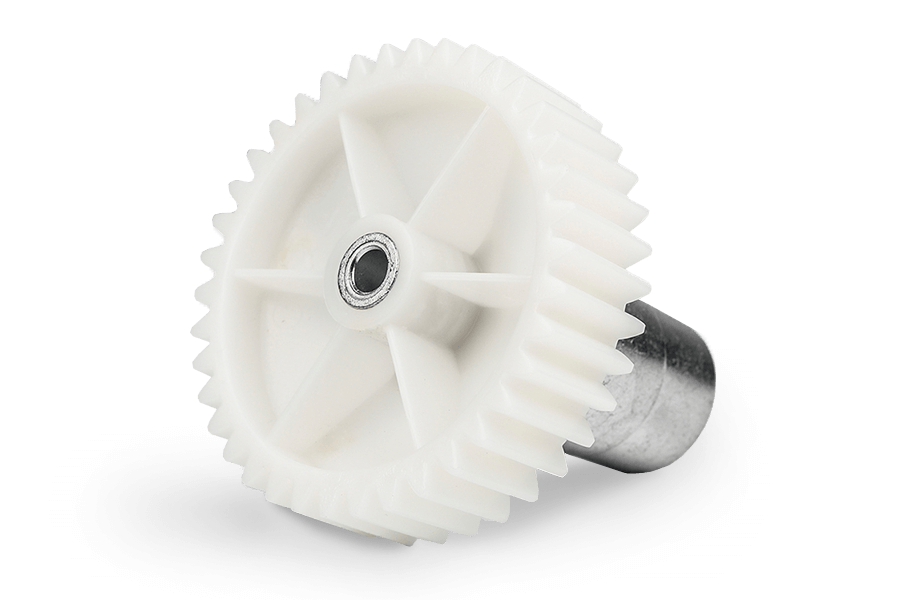

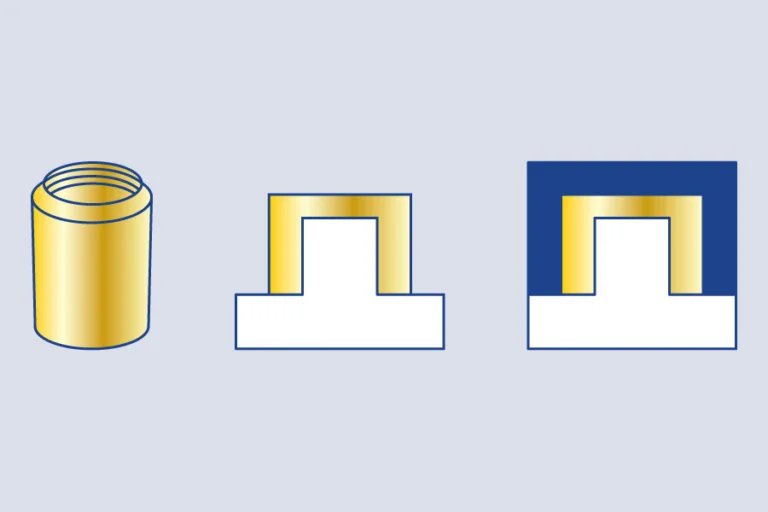

What is Insert Molding

Overmolding & Insert Molding Capabilities

| Name | Detail |

|---|---|

| Size |

78.74in. x 59.05in. x 39.37in. 2000mm x 1500mm x 1000mm |

| Mold Cavities | Single or multi-cavity |

| Mold Life | Unlimited (We will open a new mold if the old one worn out) |

| Mold Storage | Forever |

| Mold Material | P20 Steel |

| General Tolerance | Normally +/- 0.008in.(0.2mm) |

Overmolding Material

Substrate material for overmolding

Overmolding is commonly used to encapsulate one material (usually a softer or elastomeric material) over another rigid substrate. The most common substrate material for overmolding is thermoplastic, these material provides a stable base of overmolded components, the most common substrate material include:

- ABS

- PC

- Nylon

- PP

- ABS/PC

Bonding material for overmolding

The most common overmolded material is thermoplastic elastomer, known for its flexibility, resilience, and compatibility with various substrates. Some other common bonding materials include:

- TPE

- TPU

- TPV

- Silicone

Advantages of Overmolding

- Overmolding provides a protective layer, improving the overall durability and lisfespan of the product.

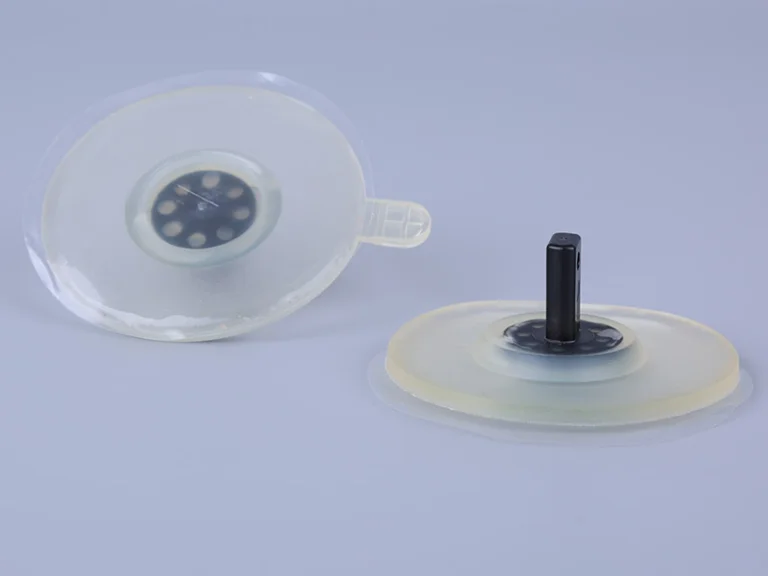

- Enables the incorporation of multiple materials with varying properties, enhanding design possibilities.

- Allows for the creation of ergonomic and comfortable surface for products like grips and handle.

- Eliminate the need for additional assembly steps, steamlining the manfuacturing process.

Advantages of Insert Molding

- Allows for the creation of stronger and more durable products by encapsulating inserts with the molding material.

- Securely encapsulated, reducing the risk of parts coming part, which enhance the integrity and reliability of the final product.

- Intergration of intricate designs and features that may be challenging or impossible with traditional assembly methods.

Why Choose Us

Ensuring accurate and intricate part production

Meeting diverse industry needs

Proven track record in successful projects

Rigorous quality checks for reliable results

FAQs of Overmolding and Insert Molding

What is the difference between overmolding and insert molding?

Overmolding involves injecting two shots of materials to form the substrated and the overmold. Insert molding only involves injecting one shot of molten plastic, though the metal insert needs to be purchased or created separately.

What is the difference between two-shot molding and overmolding?

Two-shot molding usually only makes sense for larger production runs, whereas overmolding is better for low volume production runs.

Is overmolding expensive?

Overmolded parts are made in two-step process. This increases part cycle time and is thus more expensive than molding a single part with no overmolding.

What is an example of insert molding?

Insert molding is often used to add a plastic layer on top of a metal one, for example, to add a plastic handle to a metal screwdriver. Jiangzhi can also use insert molding to manufacture insulated pipes, wiring, and other similar products, or embed electronics into plastics.