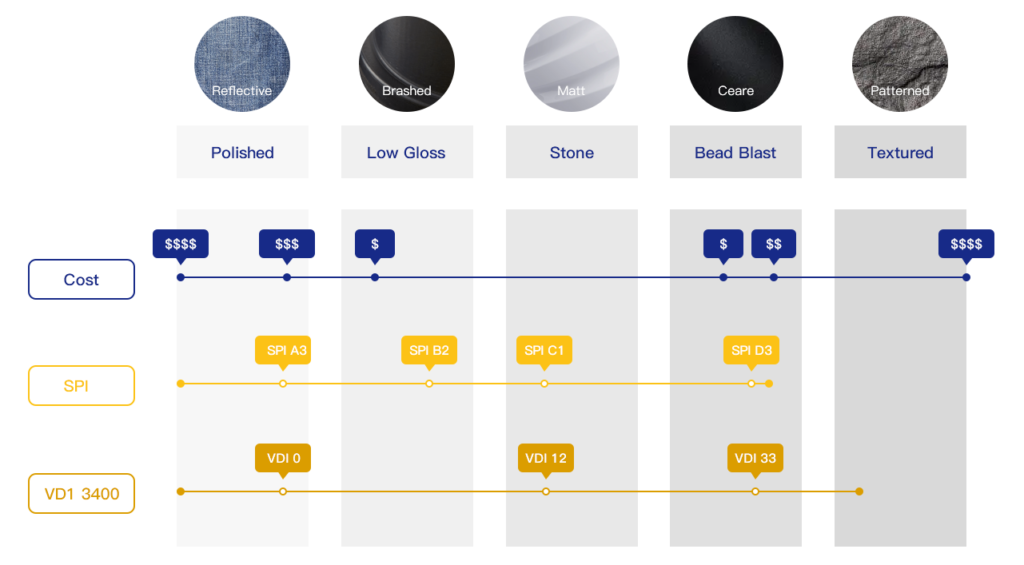

Surface Finishing Chart

Jiangzhi offers various types of injection molding finishes. Normally, our plastic surface finishing is based on SPI or VDI standards for molded parts. Finishes applied to the surface of the mold cavity transfer to the surface of the molded part. Adding a finish may change the mold price, but won’t influence the unit price. Choose the correct surface based on your own budget.

SPI Surface Finishes Chart

SPI mold finishes standard chart

| Finish | Description | Description |

|---|---|---|

| A-1 | Grade #3 diamond buff | for mirror or optical finishes |

| A-2 | Grade #6 diamond buff | most time consuming and costly finishes to achieve |

| A-3 | Grade #15 diamond buff | steel grade important to results |

| B-1 | 600# grit paper | removes all tools and machining marks |

| B-2 | 400# grit paper | provides good mold release |

| B-3 | 320# grit paper | ligh reflecting finish on molded parts, some sheen |

| C-1 | 600 stone | removes all tools and machining marks |

| C-2 | 400 stone | provides good mold release |

| C-3 | 320 stone | mute finish on molded parts, no sheen |

| D-1 | dry blast glass bead | for decorative finishes |

| D-2 | dry blast #240 oxide | helos hide shrink mardks and other imperfections |

| D-3 | dry blast #24 oxide | dull non-reflecting finish on molded parts |

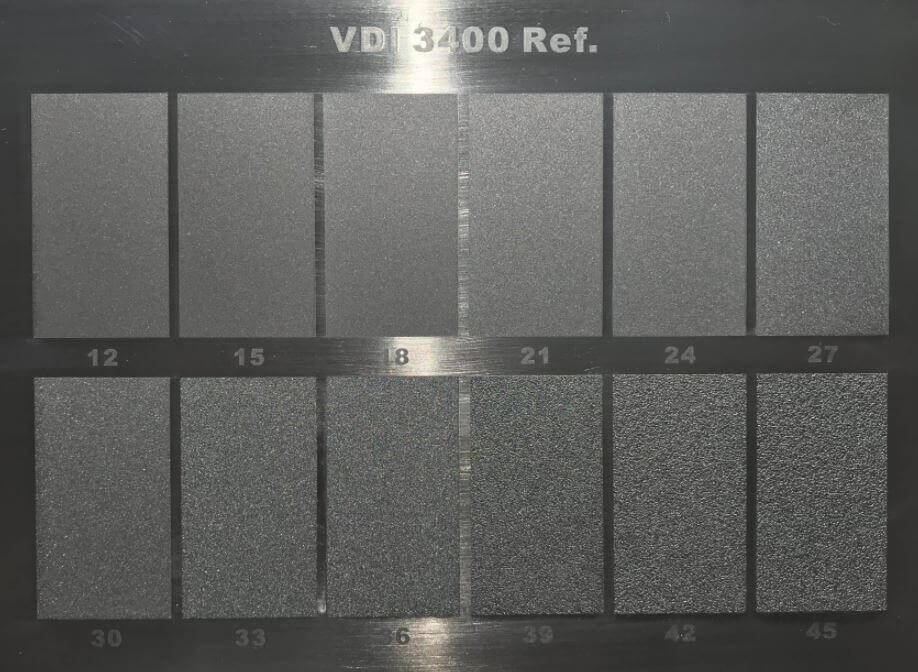

VDI 3400 Surface Finishing

Common VDI 3400 finish chart

| VDI VALUE | Description | COMMENTS |

|---|---|---|

| VDI 12 | 600 stone | low polish |

| VDI 15 | 400 stone | low polish |

| VDI 18 | dry blast glass bead | satin finish |

| VDI 21 | dry blast #240 oxide | dull finish |

| VDI 24 | dry blast #240 oxide | dull finish |

| VDI 27 | dry blast #24 oxide | dull finish |

| VDI 30 | dry blast #24 oxide | dull finish |

| VDI 33 | dry blast #24 oxide | dull finish |

| VDI 36 | dry blast #24 oxide | dull finish |

SPI vs. VDI 3400

A brief comparison between SPI standard and VDI standard

Custom Parts Surface Finishing Case

SPI A

High Gloss Finishing Part

SPI B

Semi-Gloss Finishing Part

SPI C

Matte Finishing Part

SPI D

Textured Finishing Part

Custom Contract Manufacturing Capability

Injection Molding Finishes FAQs

Popular Post

Plastic Overmolding Explained: Process, Materials, and Applications

From everyday items like toothbrushes to automotive components such as interior handles, plastic overmolding fuses two or more materials into

Polycarbonate vs Polypropylene: Key Differences, Cost & Applications

Plastics play a critical role in a wide range of industries, from automotive manufacturing to medical devices and consumer goods.

Polypropylene Machining (PP Machining Guide)

In CNC manufacturing, material properties play a decisive role in machining outcomes, including dimensional accuracy, surface quality, and process stability.