Custom Cast Molding Services

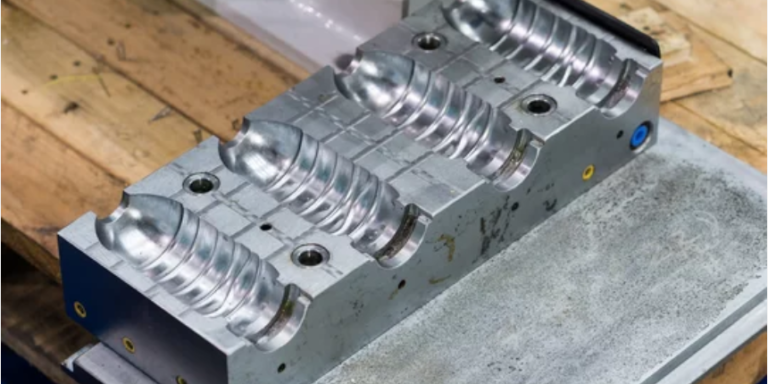

Cast Molding Capabilities

| Name | Detail |

|---|---|

| Size |

98.42in. x 78.74in. x 39.37in. 2500mm x 2000mm x 1000mm |

| Mold Cavities | Single or multi-cavity |

| Mold Life | Unlimited (We will open a new mold if the old one worn out) |

| Mold Storage | Forever |

| Mold Material | P20 Steel |

| General Tolerance | Normally +/- 0.008in.(0.2mm) |

Cast Molding Materials

Cast molding has a limitation of material selection, the most common material are as follow

- Polyurethane

- TPE

- TPU

- Nylon

Injection Molding Material Selection Guide

The material impacts the product's durability, performance, aesthetics, and cost. Choosing the right material for injection molding parts is critical to the success of any manufactureing project. Read this comprehensive guide and understand the complex process of material selection.

Custom Contract Manufacturing Capability

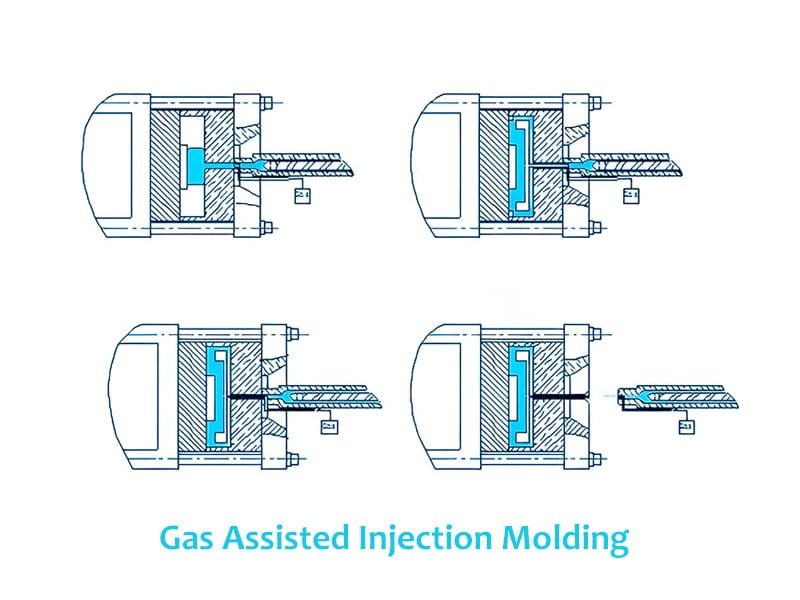

How Does Cast Molding Work

Mixing of raw materials

Melting equipment

Heating and melting of materials

Material pouring and molding

Advantages of Cast Molding

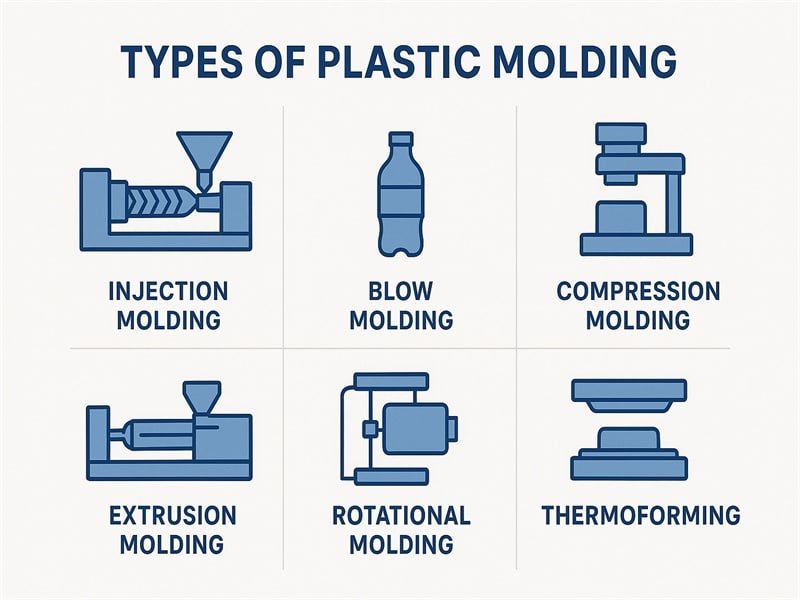

From product development models and prototypes to low-volume production runs, this rapid prototyping process is capable of producing parts that are highly similar in color, texture, feel and physical properties to injection-molded parts.

- Offers a wide variety of material choices such as rigid, flexible, durable, transparent, and high temperature resistance

- Offers physical properties similar to injection molded parts

- Suitable for low volume production

- Ability to re-mold an existing part or hardware using another material

Cast Molding Application

Cast molding is a manufacturing process with broad spectrum of applications, ranging from automotive and industrial components to medical devices and consumer products.

- Seals and gasket

- Urethane rollers

- Custom o-ring

- Vibration dampers

- Grommets and bushing

Cast Molding Parts in Different Industries

Why Choose Us

Ensuring accurate and intricate part production

Meeting diverse industry needs

Proven track record in successful projects

Rigorous quality checks for reliable results

Professional Cast Molding One-Stop Service Company

Improve production efficiency and choose efficient Cast molding solutions!

FAQs of Cast Molding

What is the lead time for urethane casting?

The speed of the urethane casting process means that you can create prototypes quickly, with lead times as low as 7 days for first articles, and 2 weeks for remaining parts.

What is the lifespan of urethane?

For example, under normal wear and tear, a duiability of more than 50 years can be expected for polyurethane insulation systems for buildings, more than 25 years for polyurethane used for insulation of refrigeraors or more than 20 years for the application of polyurethane in vehical bumpers.

What is the melting point of cast urethane?

Urethane surface temperature rapidly. This heat must be controlled. Melting can occur above 350ºF (175ºC).

Will urethane cure in cold weather?

If you try to use urethane material while it is too cold, it will not cure. If you suspect the urethane material is cold, allow it to reach room temperature (at least 73°F / 23°C) in the containers before opening.