CNC Milling Service

Jiangzhi provides custom CNC milling services for both prototypes and large-scale production. Our state-of-the-art machines ensure precise, high-quality results for intricate and complex parts. With competitive pricing starting at just $100 per part, we offer cost-effective CNC machining solutions tailored to your project. Choose from a wide range of materials and let our experienced team deliver the accuracy and efficiency you need.

What is CNC Milling?

CNC Milling Capabilities

| Name | Detail |

|---|---|

| Maximum Part Size |

78.74in. x 59.05in. x 39.37in. 2000mm x 1500mm x 1000mm |

| Distance Dimensions | For features of size (Length, width, height, diameter) and location (position, concentricity, symmetry) +/- 0.005”. |

| Precision Tolerances | ±0.1~2mm depend on part size |

| Minimum Feature Size | 0.020” (0.50 mm). This may vary depending on part geometry and chosen material. |

| Threads and Tapped Holes | We can accommodate any standard thread size. We can also machine custom threads; these will require a manual quote review. |

| Edge Condition | Sharp edges will be broken and deburred by default. Critical edges that must be left sharp should be noted and specified on a print. |

Custom Contract Manufacturing Capability

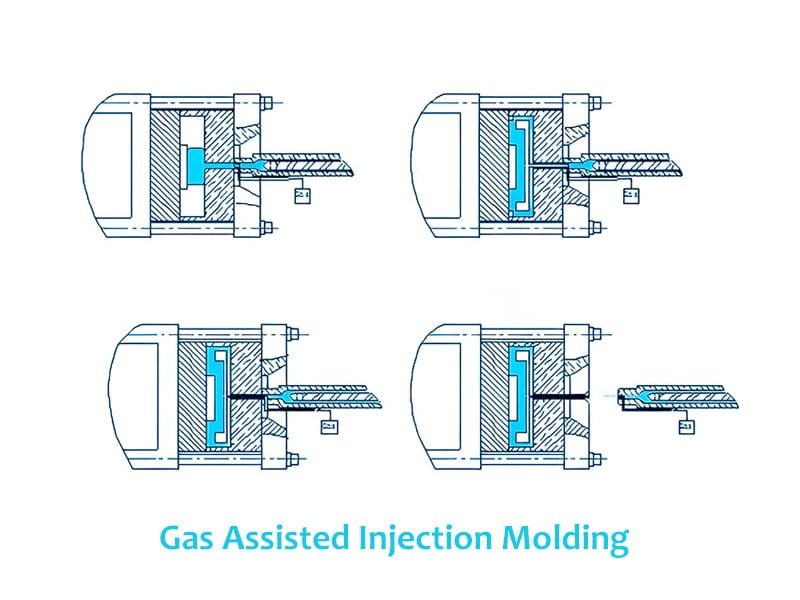

How CNC Milling Works?

The components of a CNC mill include: end mill & tool holder, tool changer, tool carousel, spindle, 2-axis milling head, air/coolant supply tubes, fixture, work piece, tool setter, x- and y-axis table.

We have multiple tool sets based on efficient cutters for a particular plastic or metal material. The machine then rapidly mills parts out of the block in a subtractive manufacturing process that uses 3- or 5-axis milling.

Machined plastic parts are left as-milled, which typically means they show visible tool marks. Some metal parts allow more finishing choices. When the run is complete and your required surface finish is applied, parts are boxed and shipped shortly thereafter.

Top 10 CNC Machining Benefits

Why Choose Us?

Ensuring accurate and intricate part production

Meeting diverse industry needs

Proven track record in successful projects

Rigorous quality checks for reliable results

Professional CNC Milling Online Service Company

Improve production efficiency and choose efficient CNC machining solutions!

FAQs of CNC Milling

What are the limitations of CNC milling?

The general limitations of CNC milling are prototypes size, axis movement, and drill bit size. The size and shape limitations will vary by the machine used.

How long does CNC milling take?

Simple parts may only take hours to produce. However, complex parts requiring 5-axis CNC machining may take weeks. It may take hours to produce. But it requires 5-axis CNC machining may take weeks.

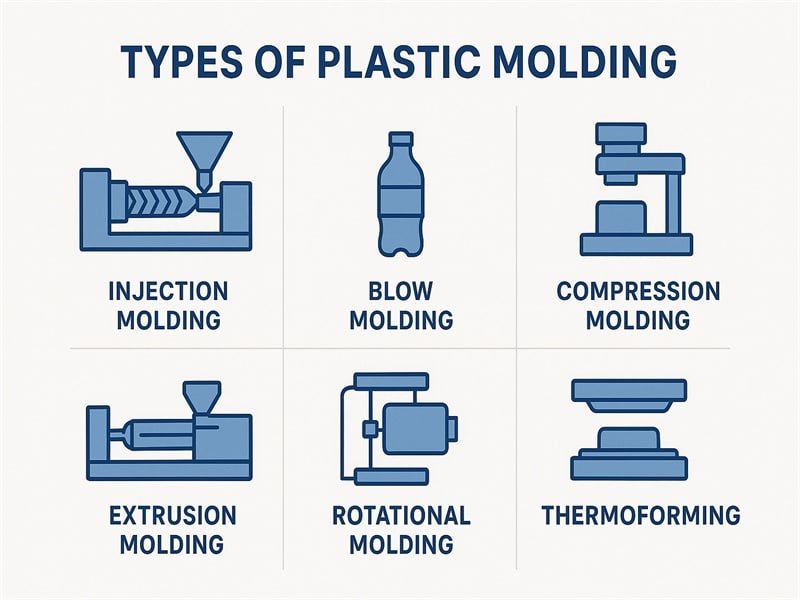

What is the alternative to CNC milling?

CNC milling machine alternative is laser cutting. The production variant with laser cutters allows you the highest precision with low maintenance costs.