CNC Turning Service

Jiangzhi offers custom CNC turning services for both prototypes and high-volume production. Our advanced machinery ensures precise, high-quality results for complex cylindrical parts. With competitive pricing starting at just $50 per part, we deliver cost-effective CNC machining solutions tailored to your specific needs. Plus, our expert team works with a variety of materials to bring your design to life with accuracy and efficiency.

What is CNC Turning?

CNC Turning Capabilities

CNC turning capabilities are crucial for producing cylindrical parts with high precision and consistency. The importance of CNC turning lies in its ability to achieve tight tolerances, smooth finishes, and intricate geometries that would be difficult or impossible with manual methods. By leveraging CNC turning, manufacturers can enhance production efficiency, reduce errors, and meet the demands for high-quality, custom parts across various industries.

Maximum Capabilities for CNC Turning

| Part size limitations | Metric units | Imperial units |

|---|---|---|

| Maximum part diameter | 431mm | 17in |

| Maximum part length | 990mm | 39in |

| Maximum swing over the carriage | 350mm | 13.7in |

| Maximum spindle through-hole | 40mm | 1.5in |

CNC Turning General Tolerances

| Description | General Tolerance |

|---|---|

| Distance Dimensions | For features of size (Length, width, height, diameter) and location (position, concentricity, symmetry) +/- 0.1mm. |

| Orientation and Form Dimensions | ±0.1~2mm depend on part size, Angularity 1/2 degree. |

| Edge Condition | Sharp edges will be broken and deburred by default. Critical edges that must be left sharp should be noted and specified on a print. |

Custom Contract Manufacturing Capability

How CNC Milling Works?

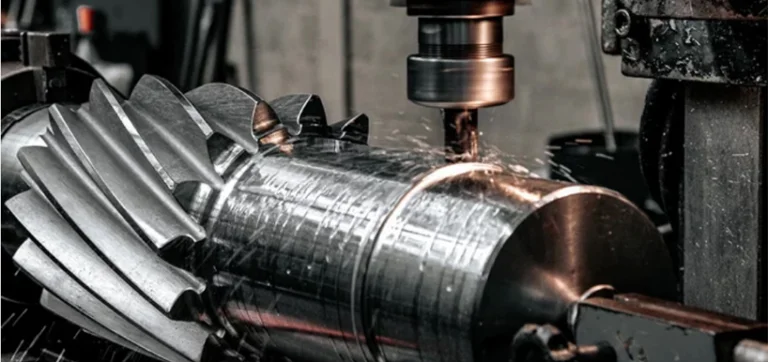

The components of a CNC lathe include: workpiece, sleeve, spindle, cutting tool and tool holder, live machining, and tool tower.

During the CNC turning process, a metal rod is rotated while a cutting tool is held against the stock to remove material and create final parts. The lathe rapidly machines your parts in a subtractive turning process with additional live tooling. Outside diameter (OD) and inside diameter (ID) threading is also available.

Turned parts can then be left as-machined, with visible tool marks, or bead blasted. When the run is complete, parts are inspected, boxed and shipped shortly thereafter.

Top 10 CNC Machining Benefits

Why Choose Us?

Choose our CNC turning service for precision, reliability, and efficient production. With state-of-the-art equipment and skilled technicians, we ensure the highest quality in creating complex, cylindrical parts. Whether it's for high-volume manufacturing or one-off prototypes, our company CNC turning service delivers exceptional accuracy, faster turnaround times, and cost-effective solutions tailored to your needs.

Ensuring accurate and intricate part production

Meeting diverse industry needs

Proven track record in successful projects

Rigorous quality checks for reliable results

Professional CNC Turning Online Service Company

Improve production efficiency and choose efficient CNC machining solutions!

FAQs of CNC Milling

What are the limitations of CNC turning?

CNC turning has some limitations like design restrictions. CNC turning is ideal for creating rotational, symmetric parts. But other methods such as CNC milling might be more appropriate for non-cylindrical parts.

What is the basic principle of CNC turning process?

As the piece rotates, a cutting tool is fed to the piece, which works at the material, cutting away to create the desired shape. Unlike other cutting sytles where the cutting tools themselves move and spin, in this case, the workpiece is rotated during the cutting process.

What materials are used in CNC turning?

The most common CNC turning materials include: aluminium, stainless steel, copper, brass, steel alloy, and various plastics.

How many types of CNC turning are there?

There are two broad categories of CNC turning centers, which include horizontal turning centers and vertical turning centers. Horizontal turning centers are far more common than their vertical counterparts.