Compression Molding Service Company

- Leading Experts in Compression Molding Solutions

- Compression Molding for Custom and Composite Components

- Delivering High-Performance and Durable Parts

- Reduce Costs and Minimize Weight with Our Molding Services

At Jiangzhi, we specialize in custom compression molding service, we deliver high-quality compression molded parts with exceptional durability and consistency. Whether you need complex compression moulding components or large, simple parts, our team helps you choose the right compression molding process and materials. With a commitment to precision and reliability, provide custom compression moulding products solutions that meet your exact specifications.

What is Compression Moulding?

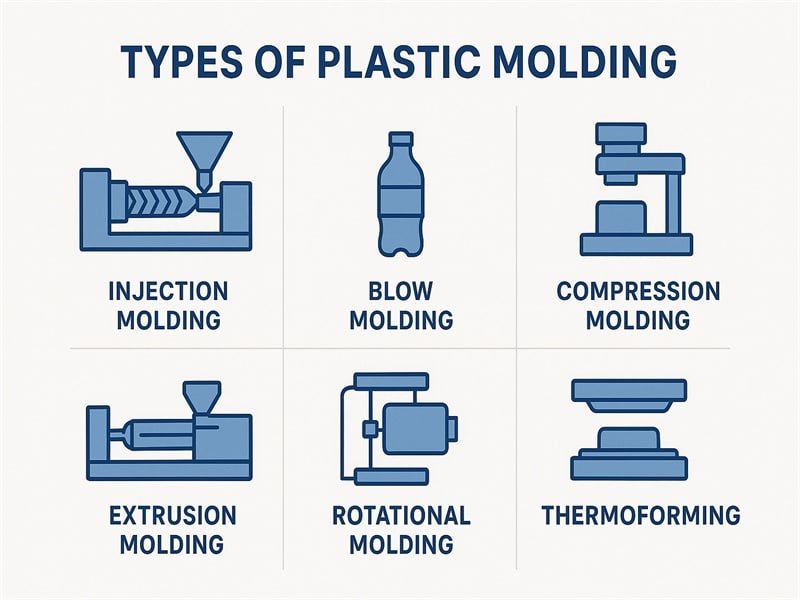

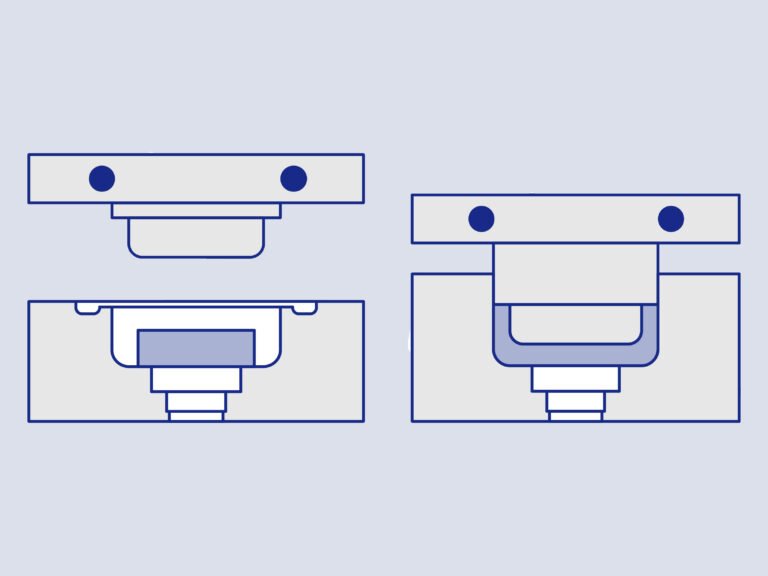

Compression molding service is a versatile and cost-effective process used to create durable, high-precision plastic and rubber parts. In this method, preheated materials are placed into a mold and compressed under pressure to form the desired shape. Ideal for both high-volume compression molding and custom compression molding needs, it is widely used in industries like automotive, electronics, and consumer goods. As a leading compression molding manufacturer, we offer tailored solutions with competitive compression molding costs and reliable, durable parts to meet your specific functional and aesthetic requirements.

Compression Molding Capabilities

Jiangzh compression molding service offer a highly efficient solution for producing strong, high-quality plastic parts. With advanced tooling and a variety of material options, we deliver cost-effective, customized results for both low and high-volume production, ensuring precision and reliability for your projects.

| Name | Detail |

|---|---|

| Size |

98.42in. x 78.74in. x 39.37in. 2500mm x 2000mm x 1000mm |

| Mold Cavities | Single or multi-cavity |

| Mold Life | Unlimited (We will open a new mold if the old one worn out) |

| Mold Storage | Forever |

| Mold Material | P20 Steel |

| General Tolerance | Normally +/- 0.008in.(0.2mm) |

Compression Moulding Materials

In compression molding process, thermosetting plastics, rubber, and composite materials are commonly used due to their ability to undergo a curing process and achieve a stable, rigid form. The selection of materials depends on the desired characteristics of the final molded products

Rubber Materials

- Silicone

- EPDM (Ethylene Propylene Diene Monomer)

- Nitrile (NBR)

- Neoprene (CR)

- SBR (Styrene Butadiene Rubber)

- Natural Rubber (NR)

- Butyl Rubber (IIR)

Plastic Materials

- UHMWPE

- PTFE

Rubber Materials Selection Guide

The material impacts the product's durability, performance, aesthetics, and cost. Choosing the right material for compression moulding parts is critical to the success of any manufactureing project. Read this comprehensive guide and understand the complex process of material selection.

Compression Molding Surface Finishing

| Finish | Description |

|---|---|

| SPI A1 | 6000 grit diamond, surper high glossy finish |

| SPI A2 | 3000 grit diamond, high glossy finish |

| SPI A3 | 1200 grit diamond, normal glossy finish |

| SPI B1 | 600 grit paper, fine semi-glossy finish |

| SPI B2 | 400 grit paper, normal semi-glossy finish |

| SPI B3 | 320 grit paper, normal semi- |

| SPI C1 | 600 grit stone, fine matte finish |

| SPI C2 | 400 grit stone, medium matte finish |

| SPI C3 | 320 grit stone, normal matte finish |

| SPI D1 | Dry blast glass bead, satin textured finish |

| SPI D2 | Dry blast, dull textured finish |

| SPI D3 | Dry blast, rough textured finish |

Custom Contract Manufacturing Capability

Our custom contract manufacturing capabilities offer custom solutions to meet the specific needs of your business. With advanced technologies and a flexible approach, we provide high-quality, cost-effective production services for a wide range of products. Whether you need small or large-scale manufacturing, we work closely with you to ensure the final product meets your exact specifications and delivery timelines.

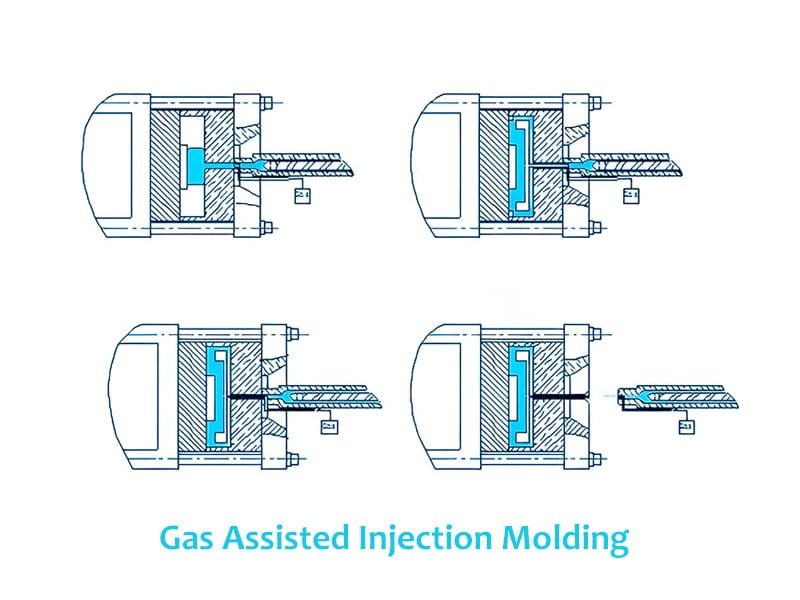

How Does Compression Molding service Process?

Material Loading

Mold Closure and Heating

Compression and Curing

Cooling

Cycling

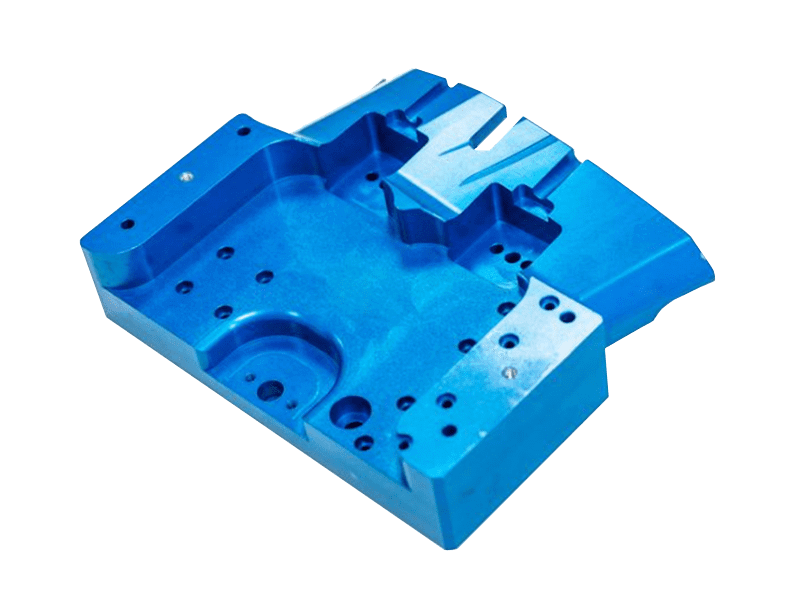

Compression Molding Examples

Advantages of Compression Molding Service

From intricate designs to high-volume production, compression moulding service stands out with its precision, efficiency, and adaptability.

- Cost-effective for large production runs due to its high prodcution output and reduced material waste.

- Ensures consistent part quality and minimal variation between parts in large batches.

- Well-suited for high-volume prodcution, contributing to faster lead times and efficient manufacturing processes.

- Minimized material waste, contributing to a more sustainable and environmentally friendly manufacturing process.

Compression Molding Application

The compression molding process produces a wide range of rubber compression molding and plastic compression molding parts across various industries. Here are some common examples:

- Rubber seals and gaskets

- Plastic insulators for electrical components

- Rubber industrial bushings

- Consumer goods handles

- Plastic enclosures for electronic devices

- Oil seal

Compression Molding Parts in Different Industries

Compression molding service is used in a wide range of industries, especially in scenarios that require high-volume production of durable, precision components. Whether in the automotive, electronics or consumer goods industries, compression molding provides efficient and reliable solutions. Next, we will delve into the specific application areas of this process.

Why Choose Us?

Choose us for compression moulding and you'll get an efficient, precise and cost-effective solution. With advanced tool technology and a wide selection of materials, we ensure customized, reliable production for your project to meet a wide range of functional and aesthetic needs to help your product stand out in the market.

Ensuring accurate and intricate part production

Our commitment to precision ensures the flawless production of intricate parts. With advanced technology and a meticulous approach, we guarantee the utmost accuracy in every detail of your compression molded components.

Meeting diverse industry needs

Our custom compression molding services address a range of industries, meeting diverse needs effectively. Whether in medical, consumer, or automotive sectors, our adaptability ensures customized solutions tailored to unique industry requirements.

Proven track record in successful projects

Our extensive track record speaks volumes about our prowess in compression moulding. Successfully completing a range of projects across various industries, we demonstrate a consistent commitment to delivering quality and meeting client expectations.

Rigorous quality checks for reliable results

Our dedication to excellence is reinforced through rigorous quality checks, ensuring consistently reliable results. Every stage of our compression molding process undergoes meticulous scrutiny, guaranteeing the delivery of top-tier and dependable outcomes.

Professional Compression Molding One-Stop Service Company

FAQs of Compression Moulding Service

What are the factores affecting compression moulding?

Before starting the compression moulding process, it’s important to consider factors like the right amount of material, heating time, and the material’s melting temperature to ensure smooth flow. You’ll also need to apply the correct pressure to shape the material properly and allow sufficient cooling time for a strong, durable product. Getting these just right will help you achieve the best results. Need advice on any of these steps? We’re here to help!

Which process is more efficient for high-volume production?

Extrusion molding is generally more efficient for high-volume production of continuous shapes, while compression moulding is more suited for medium to low-volume production of intricate parts. Specific projects have different situations, share your project!

What is the cycle time of custom compression molding service?

Compression molding require slower cycle time than injection molding, the time needed to start and repeat the sequence of operations is between 1-6 mins for compression molding.

Is compression molded cheaper than injection molding?

Injection molding is better suited to high-volume production, whereas compression molding is better suited to pliable and flexible materials. Generally, the upfront costs for compression molding are cheaper. With more project details, let Jiangzhi help you!

What is the difference between extrusion and compression molding?

Extrusion molding involves forcing material through a die to create continuous shapes like pipes or sheets, while compression molding places material into a mold that is closed and heated under pressure to form individual parts. Tangled how to choose, let Jiangzhi help for you.