Custom Large Part Injection Molding

We operate injection molding presses up to 1,000 ton to support large part applications, which can process plastic parts maximum to 2000*1500mm. Following is a lit of what you can expect from utilizing injection molding for big parts.

- In-house mold production to improve efficient and save cost

- Can process a wide range of plastic materials

- Robotics and in-house manufacturerd end-of-arm tooling ensure effcient cycle times

- Additional capabilities inclding bonding, painting, printing, assembly and custom packaging

What Is Large Part Injection Molding?

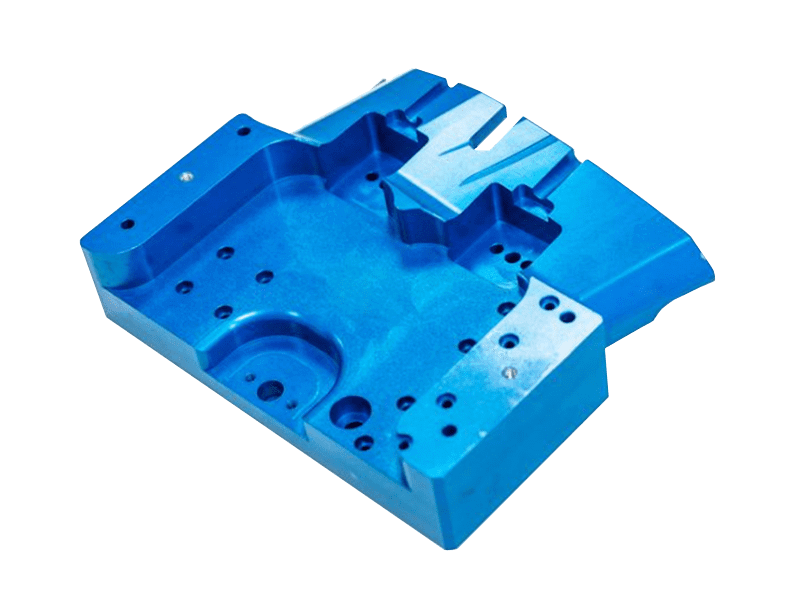

Large Part Injection Molding Mold Service

| Name | Detail |

|---|---|

| Maximun Size |

78.74in. x 59.05in. x 39.37in. 2000mm x 1500mm x 1000mm |

| Mold Cavities | Single or multi-cavity |

| Mold Life | Unlimited (We will open a new mold if the old one worn out) |

| Mold Storage | Forever (Only damage the mold after your permission) |

| Mold Material | Tool steel, stainless steel, aluminum |

| General Tolerance | Normally +/- 0.008in.(0.2mm) |

| Mold Lead Time | Generally 30~40 days for large part injection molding |

Injection Molding Large Parts Material

Large Molding Materials

Large part injection molding service often requires materials that can maintain their properties and structural integrity over larger surface areas and volumes. The typical plastic materials include:

- Polypropylene (PP)

- Polystyrene (PS)

- High-Density Polyethylene (HDPE)

- ABS (Acrylonitrile Butadiene Styrene)

- Nylon (Polyamide – PA)

- Acetal (Polyoxymethylene – POM)

- Polycarbonate (PC)

- Acrylic

Injection Moulding Large Parts Material Selection

The material used for large injection molding design can vary depending on the function of the part. Common choices include:

- Engineering plastics: For example, polycarbonate (PC), Nylon (Nylon), etc., are often used in applications requiring high strength and durability.

- Thermoplastic elastomers: such as TPE, can be used to produce parts that require flexibility.

- Fiberglass reinforced plastics: Enhance the strength, rigidity and heat resistance of plastics for parts that withstand higher mechanical loads.

Injection Molding Material Selection Guide

The material impacts the product's durability, performance, aesthetics, and cost. Choosing the right material for heavy duty injection molding is critical to the success of any manufactureing project. Read this comprehensive guide and understand the complex process of material selection.

Injection Molding Surface Finishing

| Finish | Description |

|---|---|

| SPI A1 | 6000 grit diamond, surper high glossy finish |

| SPI A2 | 3000 grit diamond, high glossy finish |

| SPI A3 | 1200 grit diamond, normal glossy finish |

| SPI B1 | 600 grit paper, fine semi-glossy finish |

| SPI B2 | 400 grit paper, normal semi-glossy finish |

| SPI B3 | 320 grit paper, normal semi- |

| SPI C1 | 600 grit stone, fine matte finish |

| SPI C2 | 400 grit stone, medium matte finish |

| SPI C3 | 320 grit stone, normal matte finish |

| SPI D1 | Dry blast glass bead, satin textured finish |

| SPI D2 | Dry blast, dull textured finish |

| SPI D3 | Dry blast, rough textured finish |

Custom Contract Manufacturing Capability

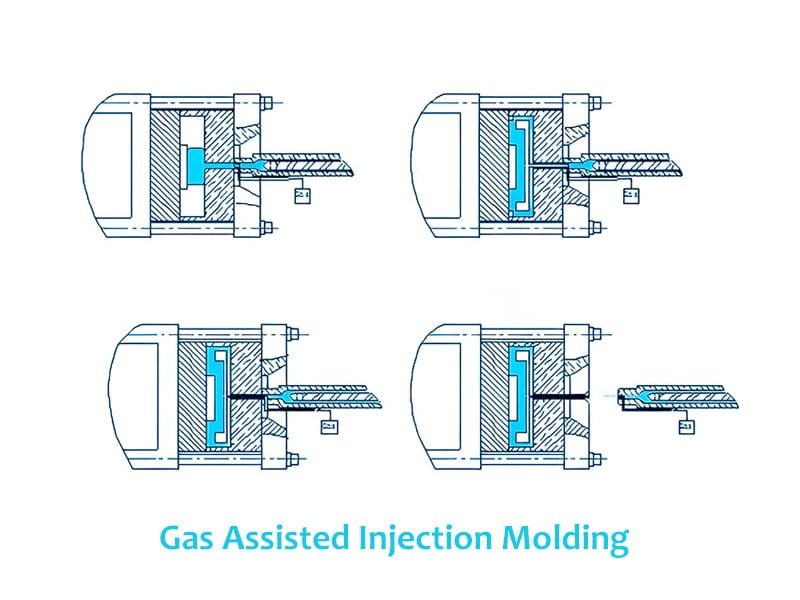

How Does Large Part Injection Molding Work?

Design Stage

Multi-cavity mold technology

Injection Molding

Post-treatment

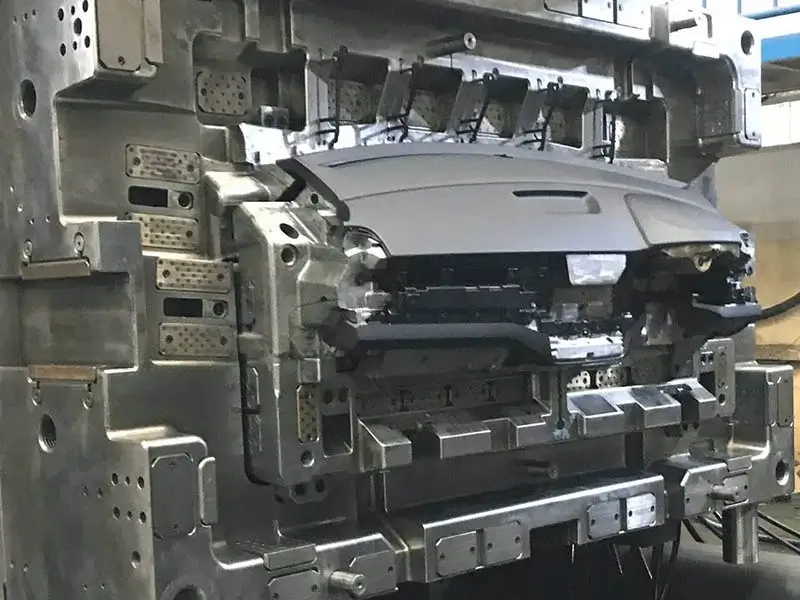

Examples of Large Plastic Injection Molding Products

Large Part Injection Molding Advantage

- High Accuracy: Ensures the exact size and shape of large components.

- High Efficiency: Suitable for mass production, reduce the cost of a single piece.

- Superior Strength: The molded parts have excellent durability and load carrying capacity.

- Material Diversity: A variety of plastic materials can be used to meet different needs.

- Complex Shape: Can produce complex design parts, reduce the need for post-processing.

- Consistency: Maintain high quality consistency in mass production.

Application of Large Injection Molding

- Dashboard Components

- Auto Interior Panels

- Washing Machine Housings

- Refrigerator Doors and Panels

- TV Enclosures

- Large Containers Packaging

- Large Building Materials

- Cable Trays and Conduits

Large Injection Molding Parts in Different Industries

Why Choose Us?

Ensuring accurate and intricate part production

Meeting diverse industry needs

Proven track record in successful projects

Rigorous quality checks for reliable results

Professional Injection Molding One-Stop Service Company

FAQs of Large Part Injection Molding

What is the cost of large part injection molding?

How long does large part injection molding take?

What materials are used in large part injection molding?

We offer a wide range of materials for large part injection molding, including engineering-grade plastics, elastomers, and composites. Our experts help you select the best material for your specific needs, whether it’s for heavy-duty injection molding or high-precision large parts.

Can you handle high-volume production for large parts?

Yes, we specialize in high-volume large part injection molding, providing custom injection molding solutions for large parts that need to be produced in bulk. Our efficient processes ensure that production runs smoothly at any scale.