Overmolding Service

Jiangzhi offers custom overmolding services for both low-volume and high-volume production. Using advanced overmolding technology, we integrate multiple materials to create durable, high-performance overmolding parts. From overmolding examples in electronics to automotive and medical devices, we provide tailored solutions for various industries. Our efficient overmolding process ensures the best fit with a wide range of substrates and elastomers. With tooling costs starting at just $500, we deliver cost-effective solutions that meet your budget and production timelines. Get in touch today for a custom over molding quote.

What is Overmolding?

Overmolding service is a versatile manufacturing process where a secondary material, such as rubber or plastic, is injected over a base part, enhancing its functionality. This technique improves grip, ergonomics, and durability, making it ideal for a variety of applications. Common overmolding examples include overmolded handles, overmolded plastic components, and rubber overmolding for added comfort. Plastic overmolding provides strength, while rubber overmoulding adds flexibility and comfort, making it suitable for products that require both durability and user-friendly design. Additionally, electronics overmolding is a key application used to protect sensitive components from environmental damage, such as moisture or impact. With our expertise in overmolded, we provide durable, cost-effective solutions that meet the unique requirements of your overmolds project.

Overmoulding Services Capabilities

| Name | Detail |

|---|---|

| Size |

200×400×100mm - 2×2×2mm 7.87×15.75×3.94 in. - 0.08×0.08×0.08in. |

| Mold Cavities | Single-cavity molds, multi-cavity molds, family molds |

| Mold Life | Unlimited (We will open a new mold if the old one worn out) |

| Mold Storage | Forever |

| General Tolerance |

+/- 0.025 mm +/- 0.00098 in. |

| Wall Thickness |

From 0.5 to 3mm From 0.20 to 0.12 in. |

| Radius |

0.1mm 0.0039in. |

| Depth |

100mm from the parting line 3.94 in. from the parting line |

| Lead Time | Starts at 7-14 business days |

Overmolding Service Materials

Choosing the right material is crucial for ensuring the performance, durability, and cost-effectiveness of your molded parts. We offer a wide range of materials, including engineering plastics, elastomers, and composites, tailored to meet the unique needs of your overmolded project. Our expert team helps you navigate the material selection process to ensure your product achieves the ideal balance of strength, flexibility, and cost.

Substrate Material for Overmolding

Overmolding is commonly used to encapsulate one material (usually a softer or elastomeric material) over another rigid substrate. The most common substrate material for over molding is thermoplastic, these material provides a stable base of overmolded components, the most common substrate material include:

Bonding Material for Overmolding

The most common overmolded material is thermoplastic elastomer, known for its flexibility, resilience, and compatibility with various substrates. Some other common bonding materials include:

- TPE

- TPU

- TPV

- Silicone

Overmolding Material Selection Guide

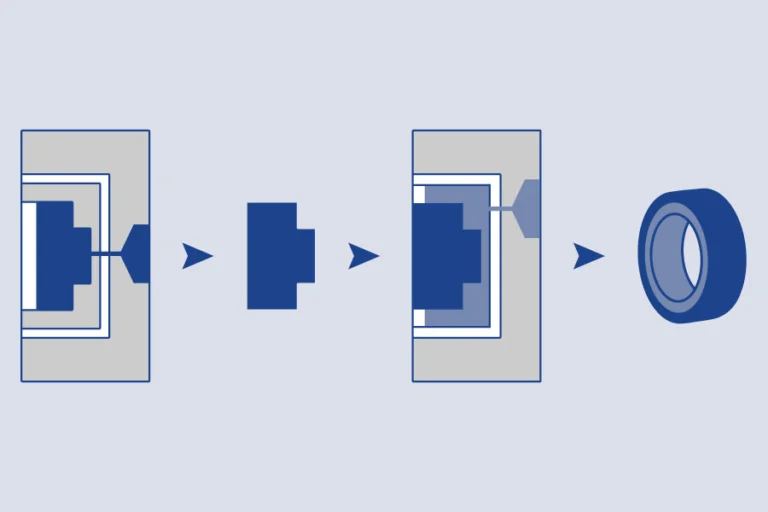

How Does Overmolding Process Work?

The over molding process involves several key steps that combine precision, innovation, and material science to create high-performance, multi-material components. Here's a breakdown of the typical overmolding process steps:

Preparation of the Base Component

The first step involves preparing the base part, which can be made from metal, plastic, or thermoplastic elastomers. The base component is cleaned and pre-treated to ensure that the secondary material bonds properly during the over molding process.

Injection of the Secondary Material

Curing or Cooling

Finishing and Inspection

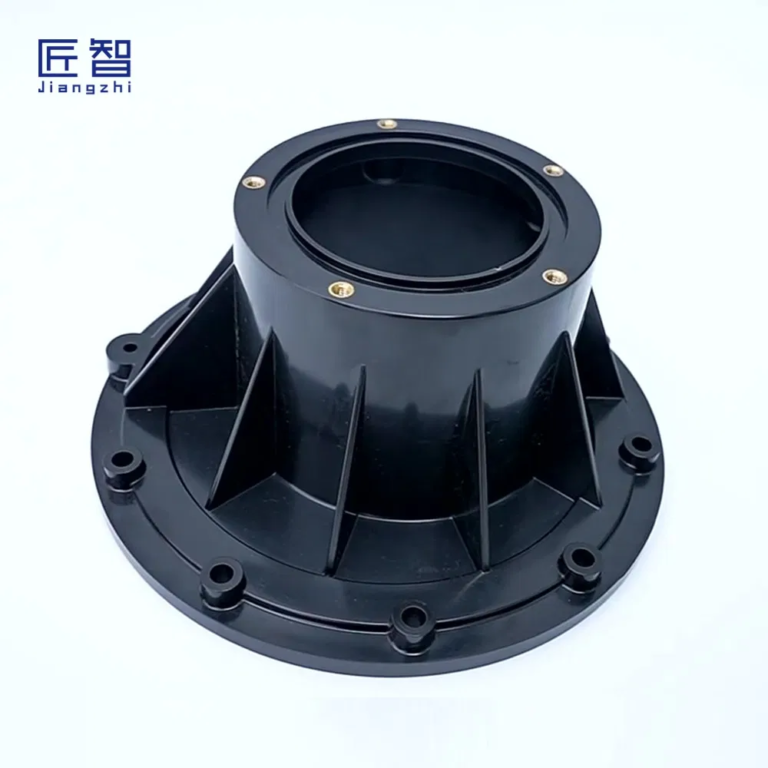

Insert and Overmolding Injection Molding Products

Advantages of Overmolding Service

- Overmoulding service provides a protective layer, improving the overall durability and lisfespan of the product.

- Enables the incorporation of multiple materials with varying properties, enhanding design possibilities.

- Allows for the creation of ergonomic and comfortable surface for products like grips and handle.

- Eliminate the need for additional assembly steps, steamlining the manfuacturing process.

Application of Overmolding Process

Overmolding service is widely used across various industries due to its ability to enhance product functionality and aesthetics by combining multiple materials. Common applications include:

- Cable connectors

- Soft-touch grips on devices

- Buttons

- Handles

- Protective housing

- Toothbrushes

Overmolding Parts in Different Industries

Overmoulding is a versatile technique used across various industries to enhance the functionality and design of components. From automotive and electronics to medical devices and consumer goods, overmolding provides solutions for ergonomic grips, sealing, electrical insulation, and more. This process allows for the creation of durable, multi-material parts that meet the specific needs of each industry.

Why Choose Us?

Ensuring accurate and intricate part production

Meeting diverse industry needs

Our over molding services address a range of industries, meeting diverse needs effectively. Whether in medical, consumer, or automotive sectors, our adaptability ensures customized solutions tailored to unique industry requirements.

Proven track record in successful projects

Our extensive track record speaks volumes about our prowess in injection molding overmolding. Successfully completing a range of projects across various industries, we demonstrate a consistent commitment to delivering quality and meeting client expectations.

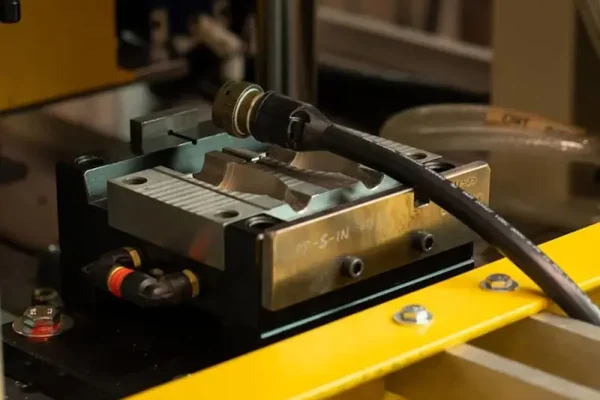

Rigorous quality checks for reliable results

Our dedication to excellence is reinforced through rigorous quality checks, ensuring consistently reliable results. Every stage of our overmolding injection molding process undergoes meticulous scrutiny, guaranteeing the delivery of top-tier and dependable outcomes.

Professional Overmolding One-Stop Service Company

FAQs of Overmolding Process

What is the difference between overmolding and insert molding?

Overmolding involves injecting a secondary material over a base part, such as rubber over a plastic handle, to enhance features like grip, comfort, or durability. In contrast, insert molding involves placing a pre-formed insert, like metal or plastic, into the mold, and then injecting plastic around it to create a part with added strength or functionality. While overmolding focuses on adding soft or protective layers, insert molding integrates dissimilar materials for enhanced structural integrity. Both techniques have unique benefits and are used to enhance the functionality and performance of plastic components, but the choice between them depends on the specific needs of your project.

What is low pressure overmolding?

Low pressure overmolding is a specialized overmolding process where a secondary material is injected over a base part at lower injection pressures compared to traditional overmolding. This method is typically used for more delicate or complex parts where high pressure might cause damage or deformation.

Can I use overmolding for complex designs?

Yes! Overmolding is ideal for custom overmolding solutions and complex designs. Whether you need to combine multiple materials or create overmolded plastic parts, our process can achieve high-quality, functional products tailored to your specifications.

What are the benefits of rubber overmolding?

Rubber overmolding adds a comfortable, soft touch to products while improving grip and ergonomics. It’s commonly used for overmolded handles and medical devices, offering durability and a better user experience.

What is overmolding injection molding?

Overmolding is a specialized form of injection molding where a secondary material is injected over a base part, usually made from a rigid material like plastic or metal. This secondary layer enhances the part’s functionality, such as improving grip, comfort, or protection. Injection molding, in general, refers to the process of injecting a single material into a mold to form a part.

How long does the overmolding process take compared to injection molding?

The overmolding process typically takes longer than injection molding because of the additional steps involved, including the injection of the second material. However, the difference in time may not be significant for small to medium batch runs, and the time investment may be justified by the improved performance