Overmolding and Insert Molding Service

What is Overmolding Service?

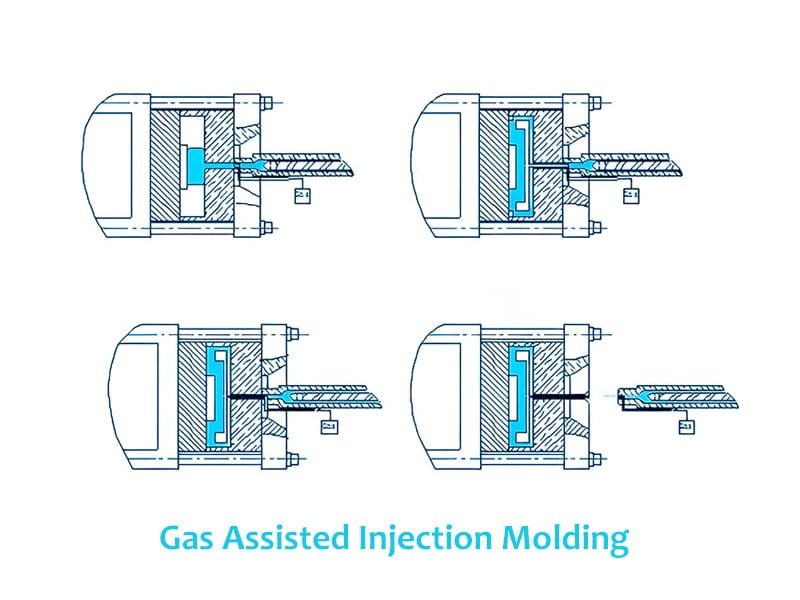

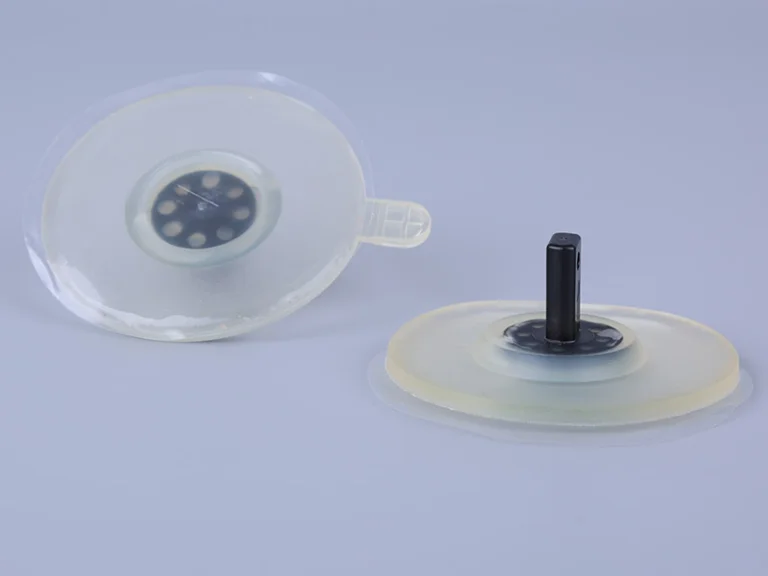

Overmolding is a process of taking a substrate parts and then using injection molding to add additional layers over it, like thermoplastic or silicone rubber material. Traditionally, the substrate parts are plastic or metal with higher melting point, once that parts is cooled, the layer is injection molded over it. So the cycle time is a bit longer. Usually overmolding is used to create a grip or roller.

Overmoulding Application Examples:

- Power tool handles

- Medical devices (enhanced grip)

- Consumer electronics (non-slip function)

What is Insert Molding Service?

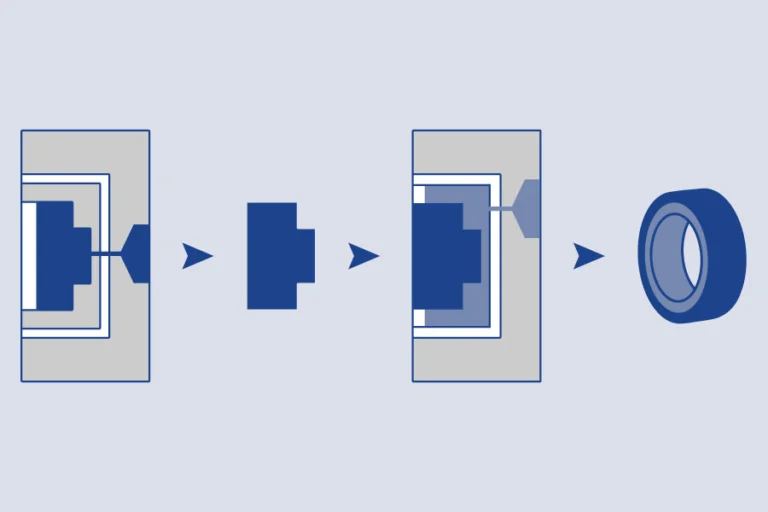

Insert molding refers to pre-installing the insert in the mold and injecting resin. The molten resin is combined with the insert to melt. The insert is usually metal, and the injected plastic material is usually rigid plastic. During the molding process, the insert usually needs to be preheated so that its surface temperature is close to the melting point of the cover material for optimal bonding.

- Electronic products (connectors)

- Automotive parts (engine fasteners)

- Medical devices (implant parts)

Overmolding & Insert Molding Capabilities

| Name | Detail |

|---|---|

| Size |

78.74in. x 59.05in. x 39.37in. 2000mm x 1500mm x 1000mm |

| Mold Cavities | Single or multi-cavity |

| Mold Life | Unlimited (We will open a new mold if the old one worn out) |

| Mold Storage | Forever |

| Mold Material | P20 Steel |

| General Tolerance | Normally +/- 0.008in.(0.2mm) |

Overmolding and Insert Molding Material

Overmolding General Material

A substrate is formed first, and then a second injection molding is performed to form a coating.

Common Materials:

- Substrate Material: ABS, Polycarbonate (PC), Nylon, PP, PEEK

- Coating Material: TPE, TPU, TPV, Silicone

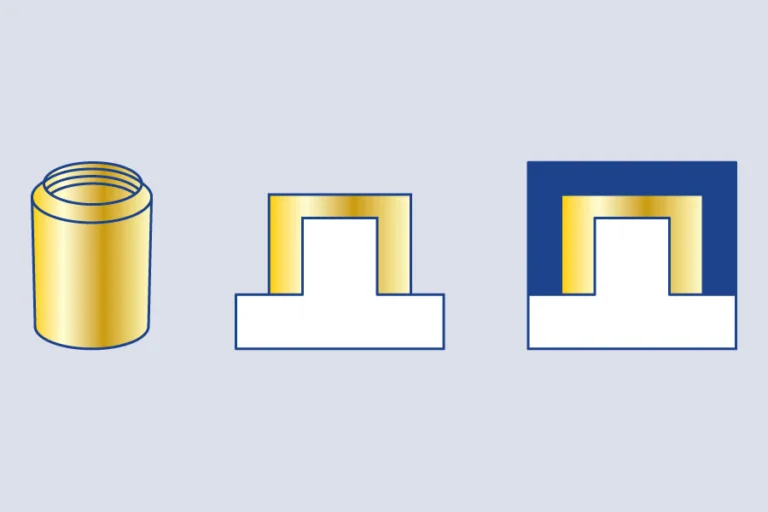

Insert Molding General Material

Pre-inserted metal parts are encapsulated by injected plastic, then cooled and solidified into a single, durable component.

Common Materials:

- Metal inserts: steel, stainless steel, brass, aluminum

- Plastic: Nylon, ABS, PC, PBT

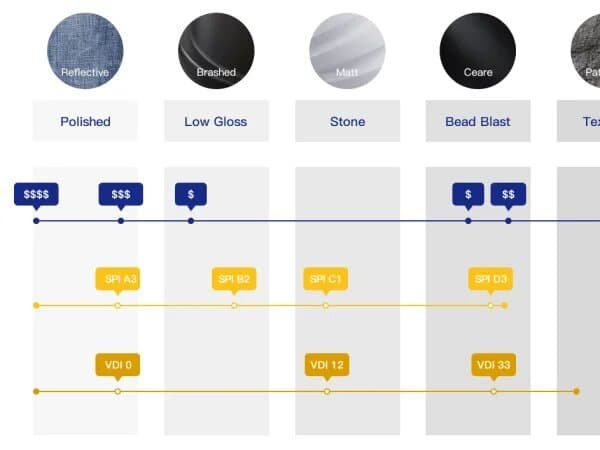

Injection Molding Material Selection Guide

Cost Analysis: Overmolding vs. Insert Molding

Overmolding Cost

- Requires additional mold design (two-step process)

- Requires more material (soft overmoulding)

- Suitable for high volume production, otherwise higher cost

Insert Molding Cost

- Metal inserts need to be purchased, but subsequent assembly can be reduced

- Suitable for automated production, reducing labor costs

Advantages of Overmolding

- Enhanced Grip & Comfort – Provides better grip and comfort, ideal for tool handles and consumer electronics.

- Improved Durability – Enhances wear resistance and impact strength with a protective overmold layer.

- Seamless Integration – Ensures strong material bonding and improved sealing properties.

- Aesthetic & Functional Design – Adds soft-touch feel while improving product appearance, suitable for medical devices and electronics.

- Vibration & Shock Absorption – Reduces vibration impact, extending product lifespan in automotive and industrial applications.

Advantages of Insert Molding

- Stronger Metal-Plastic Bonding – Integrates metal and plastic in a single process, enhancing mechanical strength for electronic connectors and automotive components.

- Reduced Assembly Time & Cost – Eliminates manual assembly, increasing production efficiency for mass manufacturing.

- Lightweight Yet Durable – Replaces some metal parts with plastic, reducing weight while maintaining strength.

- Design Flexibility – Enables complex geometries and precise multi-functional components.

- Improved Product Reliability – Prevents metal inserts from loosening, ensuring stable electrical and mechanical connections, ideal for medical devices and aerospace applications.

Why Choose Jiangzhi Your Overmolding Manufacturer

Strong integration ability

Experienced engineering service

Quality is priority

Specialize in assembly

Logistics & fulfillment

Full-process Service Capabilities

FAQs of Overmoulding and Insert Molding

What is the difference between overmolding and insert molding?

Overmolding involves injecting two shots of materials to form the substrated and the overmold. Insert molding only involves injecting one shot of molten plastic, though the metal insert needs to be purchased or created separately.

What is the difference between two-shot molding and overmolding?

Two-shot molding usually only makes sense for larger production runs, whereas overmolding is better for low volume production runs.

Is overmolding expensive?

Overmolded parts are made in two-step process. This increases part cycle time and is thus more expensive than molding a single part with no overmolding.

What is an example of insert molding?

Insert molding is often used to add a plastic layer on top of a metal one, for example, to add a plastic handle to a metal screwdriver. Jiangzhi can also use insert molding to manufacture insulated pipes, wiring, and other similar products, or embed electronics into plastics.