Custom Plastic Injection Molding Service

- One-stop Service: design, mold making, molding, finishing, etc.

- Mold costs start at only $500.

- 40+ years injection molding factory experience.

- ISO9001:2015 Certified.

Jiangzhi as a plastic Injection molding service manufacturer for both low-volume and end-use production. Typically, we use steel as the tooling material to ensure plastic molded durability. Our mold costs start at only $500. Additionally, we provide a variety of plastic resins, allowing you to choose the perfect material for your project.

Jump to Section

What is Plastic Injection Molding?

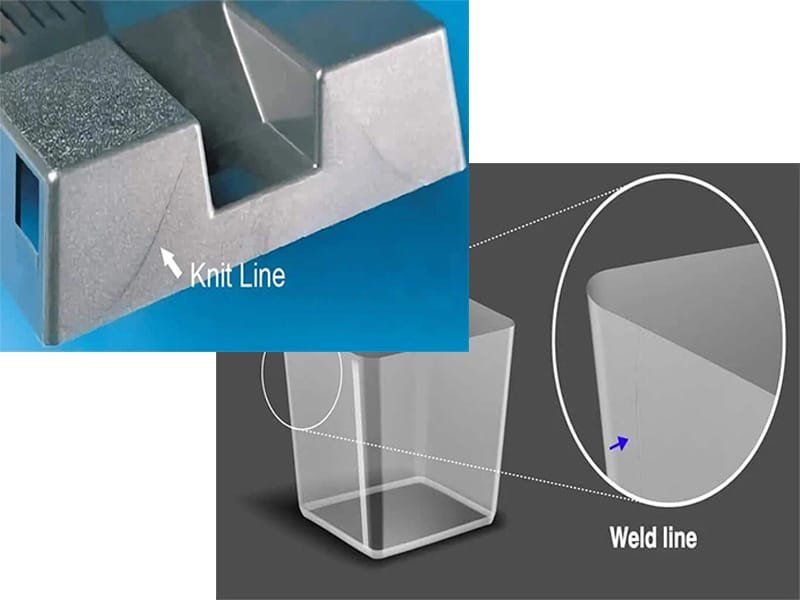

Custom plastic injection molding services is a manufacturing process where molten plastic is injected into a mold cavity to form a specific shape, which is then cooled and solidified into a final part. It is commonly employed for large-scale production of plastic components due to its minimal material waste and low cost per unit. This makes it an optimal manufacturing method for sectors such as medical devices, consumer goods, and automotive.

Furthermore, proper mold design and careful control of molding conditions are crucial for producing high-quality parts. Explore our mold & tooling service and quality management.

Plastic Injection Molding Service

Plastic injection molding is an efficient and cost-effective manufacturing process used to produce high-precision plastic parts. It offers flexibility in design and material choice, making it ideal for a wide range of industries. With optimized custom plastic molds and tailored solutions, we deliver custom plastic products to meet various functional and aesthetic needs.

| Name | Detail |

|---|---|

| Size |

78.74in. x 59.05in. x 39.37in. 2000mm x 1500mm x 1000mm |

| Mold Cavities | Single-cavity molds, multi-cavity molds, family molds |

| Mold Life | Unlimited (We will open a new mold if the old one worn out) |

| Mold Storage | Forever |

| Mold Material | P20 Steel |

| General Tolerance | Normally +/- 0.008in.(0.2mm) or less |

| Wall Thickness | 0.5 mm to 5 mm |

| Tooling | Rapid Tooling: recommended for 100-10,000 parts / Production Tooling: recommended for over 10,000 parts |

| Lead Time | Starts at 7-14 business days |

Plastic Injection Molding Material

Our plastic injection molding services utilizes a diverse range of injection moldable plastics, catering to various applications across industries. When selecting the right material for your project, factors such as impact strength, rigidity, thermal and chemical resistance should be considered. Our common plastic injection moulding materials include:

Plastic Materials

- ABS

- PC (Polycarbonate)

- PP (Polypropylene)

- POM (Acetal)

- PE (Polyethylene)

- PS (Polystyrene)

- PVC (Polyvinyl Chloride)

- PU (Polyurethane)

- PA (Nylon)

- PMMA (Acrylic)

- HDPE (High-Density Polyethylene)

- LDPE (Low-Density Polyethylene)

- PC/ABS (Polycarbonate/Acrylonitrile Butadiene Styrene)

Additives

- UV absorbers

- Colorants

- Flame retardants

- Glass fiber

- Plasticizers

Injection Molding Material Selection Guide

The material impacts the product's durability, performance, aesthetics, and cost. Choosing the right material for injection molding parts is critical to the success of any manufactureing project. Read this comprehensive guide and understand the complex process of material selection.

Plastic Injection Molding Factory Surface Finishing

| Finish | Description |

|---|---|

| SPI A1 | 6000 grit diamond, surper high glossy finish |

| SPI A2 | 3000 grit diamond, high glossy finish |

| SPI A3 | 1200 grit diamond, normal glossy finish |

| SPI B1 | 600 grit paper, fine semi-glossy finish |

| SPI B2 | 400 grit paper, normal semi-glossy finish |

| SPI B3 | 320 grit paper, normal semi- |

| SPI C1 | 600 grit stone, fine matte finish |

| SPI C2 | 400 grit stone, medium matte finish |

| SPI C3 | 320 grit stone, normal matte finish |

| SPI D1 | Dry blast glass bead, satin textured finish |

| SPI D2 | Dry blast, dull textured finish |

| SPI D3 | Dry blast, rough textured finish |

Custom Contract Manufacturing Capability

How Does Custom Plastic Injection Molding Work?

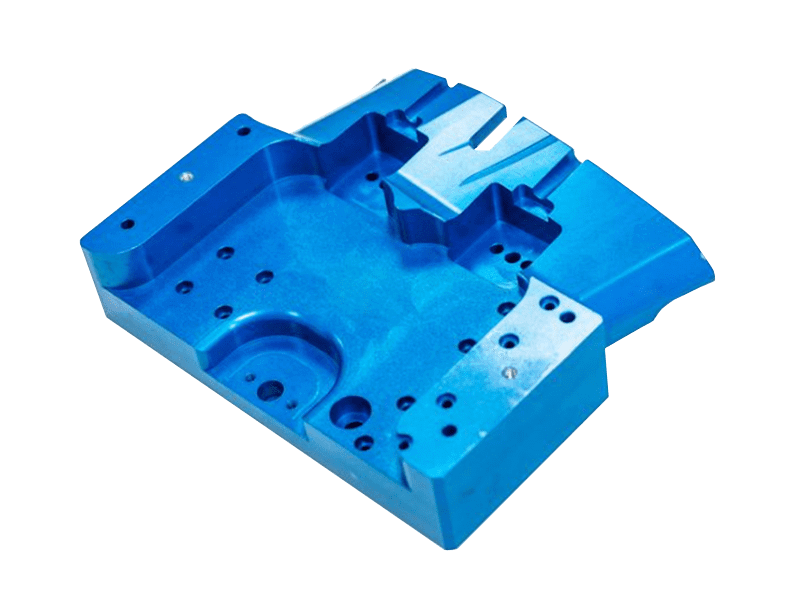

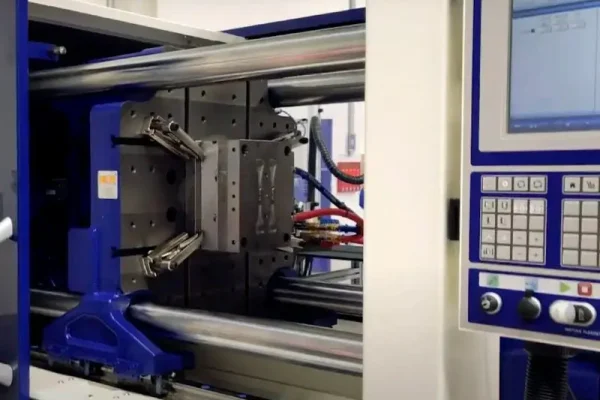

Our plastic molding manufacturing is a highly efficient method for producing a wide range of plastic parts. Our advanced machinery and experienced team ensure precise control over each step of the process, resulting in high-quality, consistent, and cost-effective production of plastic components. The process involves several key steps:

Mold Creation

Injection

Cooling

Ejection

Once the plastic has solidified, the plastic mold injection is opened, and the newly formed part is ejected. This completes the injection molding process cycle.

Plastic Injection Molding Examples

Advantages of Injection Molding

From intricate designs to high-volume production, Injection Molding stands out with its precision, efficiency, and adaptability.

- Low scrap rate Keeping high productivity

- Available for a wide range of materials

- Craft components with complex geometries

- Ensure consistent and repeatable quality

- Boost look with diverse finishes

- Low cost at higher volumes

Plastic Injection Molding Application

Injection molding is an efficient manufacturing process that is widely used in the production of plastic parts.

- Home Appliance Components

- Packaging Materials, Food Containers

- Phone Casings, Computer Accessories

- Tail Light Housings, Dashboards

- Office Supplies, File Folders, Staplers

- Plastic Toys, Plastic Containers, Plastic Pipes

Plastic Injection Parts in Different Industries

Custom plastic injection molding service is widely used in many industries, including consumer goods, automotive, electronics, medical and packaging. It offers high precision, cost effective and flexible design for a wide range of products that meet the needs of different industries for complex shapes and functions.

Why Choose Us?

Choose us for your injection molding needs, and you’ll benefit from high-quality, precise, and efficient production services. With advanced technology, an experienced team, and flexible manufacturing capabilities, we meet a wide range of custom requirements. Whether it's complex designs or large-scale production, as a professionnal injeciton molding company ensure timely delivery and top-notch quality, providing strong support for your business.

Ensuring accurate and intricate part production

Meeting diverse industry needs

Our plastic injection moulding services address a range of industries, meeting diverse needs effectively. Whether in medical, consumer, or automotive sectors, our adaptability ensures customized solutions tailored to unique industry requirements.

Proven track record in successful projects

Rigorous quality checks for reliable results

Professional Injection Molding One-Stop Service Company

Improve production efficiency and choose efficient plastic injection molding service solutions!

Useful Injection Molding Process Resources

FAQs of Plastic Injection Molding services

What is the hardest plastic for injection molding?

Polycarbonate is one of the most shatter-resistant plastic materials available for use in injection molding.

How Do I Choose the Best Injection Molding Supplier?

Choosing the right injection molding supplier is crucial for ensuring quality and cost-efficiency. Look for companies with experience in the specific materials and processes you need, such as precision injection molding or medical injection molding. It’s important to evaluate their ability to provide custom injection molding solutions and their capacity to handle both low and high-volume production efficiently. Jiangzhi professional injection molding one-stop service company, will be the most suitable choice

How Much Does Custom Injection Molding Cost?

How long does custom plastic injection molding take?

The lead-time for a plastic injection molding mold can be quite variable and depends on several factors. In general, you can expect the lead-time to range between 4-12 weeks, but even this timeframe could vary depending on complexity and scale of production.

What materials are suitable for plastic injection molding?

Injection molding supports a wide range of materials, including thermoplastics like ABS, polycarbonate, and polypropylene, as well as elastomers and composite materials. Choosing the right material depends on the desired part properties and the industry requirements, such as medical-grade materials for injection molding medical parts.

What is the minimum injection molding order quantity?

Our minimum order size is flexible and can be adjusted according to customer needs. Whether it is small batch customization or high volume production, we can provide efficient production solutions.

What is the usual lead time for injection molding?

Delivery time depends on the complexity and quantity of the order. Generally speaking, from mold design to product delivery, it usually takes 4-6 weeks. We also offer rapid prototyping services to help you achieve product development faster.