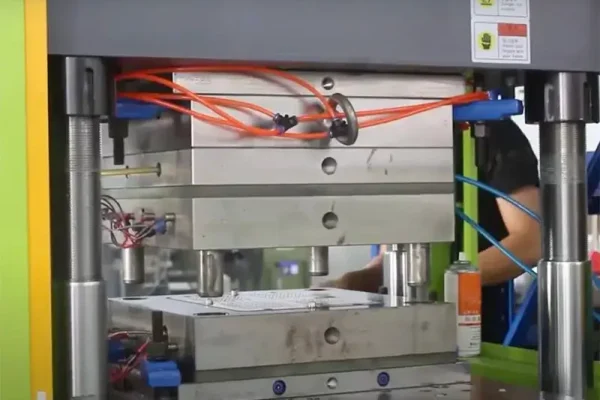

Injection Rubber Molding Service

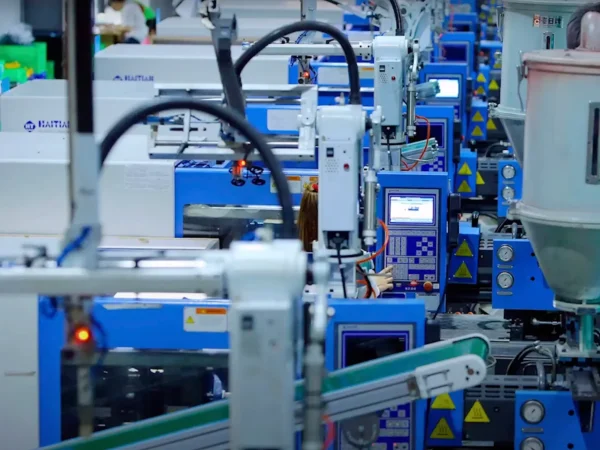

Jiangzhi specializes in injection rubber molding manufacturer, catering to both low-volume production and end-use manufacturing. Our high-quality molds, typically crafted from steel, ensure exceptional durability. Starting at just $500, our mold costs are highly competitive. We offer a diverse range of rubber materials, ensuring you can choose the perfect rubber compound for your injection molding rubber project, whether it’s for prototype development or large-scale production.

What Is Injection Rubber Molding?

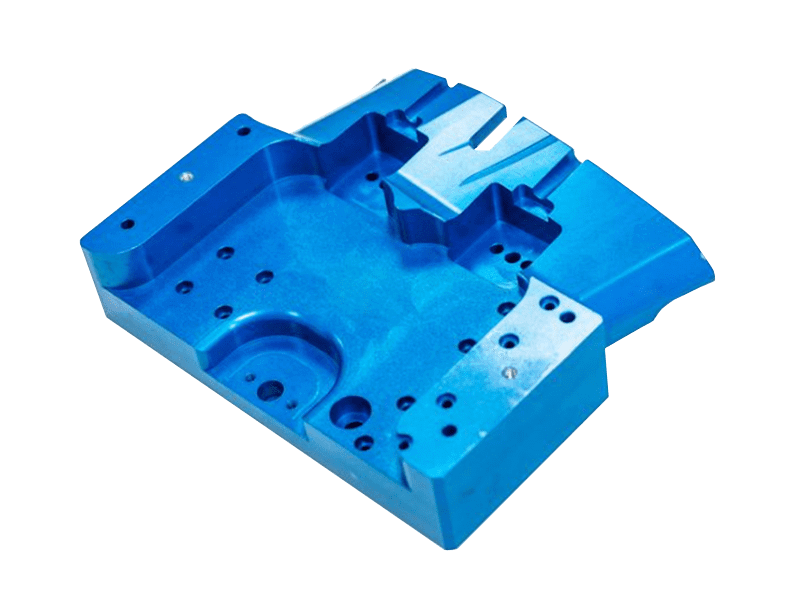

Rubber injection molding is a manufacturing process where rubber is injected into a custom mold under high pressure, then heated to cure and harden into the desired shape. This method produces precise, durable, and complex rubber parts with consistent quality, making it ideal for both low-volume and high-volume production. It’s commonly used to create parts like seals, gaskets, and other custom rubber components across various industries, including automotive, medical, and consumer goods. Injection rubber molding offers exceptional design flexibility, the ability to use a wide range of rubber materials, and ensures high production efficiency, making it a preferred choice for manufacturers.Injection Mold Rubber Capabilities

| Name | Detail |

|---|---|

| Size |

78.74in. x 59.05in. x 39.37in. 2000mm x 1500mm x 1000mm |

| Mold Cavities | Single or multi-cavity |

| Mold Life | Unlimited (We will open a new mold if the old one worn out) |

| Mold Storage | Forever |

| Mold Material | P20 Steel |

| General Tolerance | Normally +/- 0.008in.(0.2mm) |

Injection Rubber Molding Material

Rubber Materials

- Silicone

- Ethylene Propylene Diene Monomer (EPDM)

- Nitrile (NBR)

- Neoprene (CR)

- Styrene Butadiene Rubber (SBR)

- Natural Rubber (NR)

- Butyl Rubber (IIR)

- Fluoroelastomer(FKM)

Additives

- Softeners

- Colorants

- UV Stabilizers

- Flame Retardants

- Lubricants

- Reinforcing Agents

Rubber Materials Selection Guide

The material impacts the product's durability, performance, aesthetics, and cost. Choosing the right material for rubber molding parts is critical to the success of any manufactureing project. Read this comprehensive guide and understand the complex process of material selection.

Custom Rubber Molding Surface Finishing

We offer a variety of surface treatments for molded rubber components, including smooth, glossy, textured, and matte finishes. Our standard option is SPI finishing, with VDI finishes also available upon request, allowing you to choose the perfect surface texture to meet your rubber mold design or custom rubber parts specifications and functional requirements. These treatments not only enhance the appearance but also improve the performance and longevity of your rubber components.

| Finish | Description |

|---|---|

| SPI A1 | 6000 grit diamond, surper high glossy finish |

| SPI A2 | 3000 grit diamond, high glossy finish |

| SPI A3 | 1200 grit diamond, normal glossy finish |

| SPI B1 | 600 grit paper, fine semi-glossy finish |

| SPI B2 | 400 grit paper, normal semi-glossy finish |

| SPI B3 | 320 grit paper, normal semi- |

| SPI C1 | 600 grit stone, fine matte finish |

| SPI C2 | 400 grit stone, medium matte finish |

| SPI C3 | 320 grit stone, normal matte finish |

| SPI D1 | Dry blast glass bead, satin textured finish |

| SPI D2 | Dry blast, dull textured finish |

| SPI D3 | Dry blast, rough textured finish |

Custom Contract Manufacturing Capability

Our custom contract manufacturing capabilities offer custom solutions to meet the specific needs of your business. With advanced technologies and a flexible approach, we provide high-quality, cost-effective production services for a wide range of products. Whether you need small or large-scale manufacturing, we work closely with you to ensure the final product meets your exact specifications and delivery timelines.

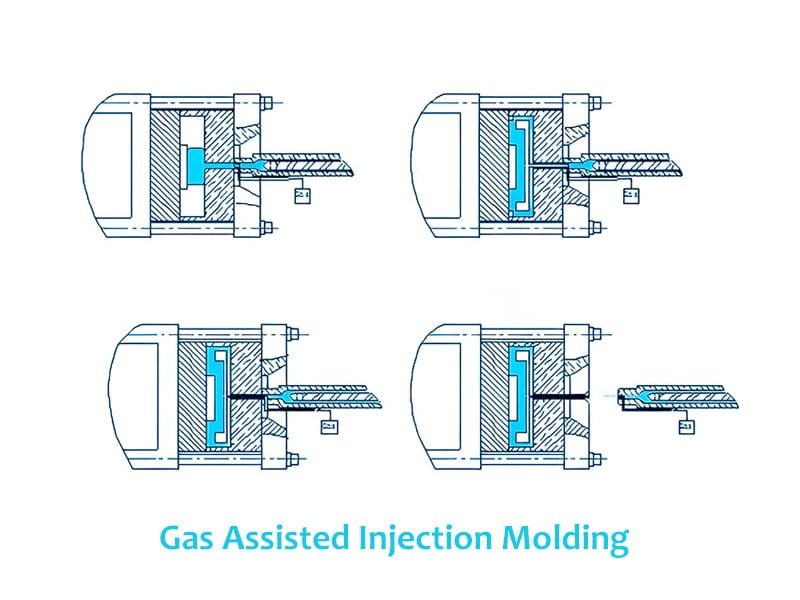

How Does Rubber Injection Molding Work?

Material Preparation

Injection Molding

Curing or Vulcanization

Cooling and Ejection(Demolding)

After curing, the mold is cooled, solidifying the rubber part. Once cooled, the mold is opened, and the finished molded rubber parts are ejected. Excess material, such as flash, is trimmed off to ensure a smooth finish.

Advantages of Injection Molding Rubber

- High accuracy and consistency

- Improve production efficiency

- High material utilization

- Adapt to complex design

- Reduced labor costs

- Reduced post-processing requirements:

Rubber Mold Injection Application

- Seals

- Gaskets and washers

- Rubber buttons

- Belts

- Bottle stoppers

- Automotive cushions

- Rubber hoses

Rubber Molding Parts in Different Industries

Rubber molded parts play a crucial role across various industries, offering exceptional durability, flexibility, and resistance to harsh conditions. From automotive seals to medical devices and consumer goods, molded rubber components are essential for ensuring product performance and longevity. Whether it's for creating custom gaskets, vibration dampeners, or protective covers, rubber molding provides versatile solutions that meet the unique needs of each sector.

Why Choose Us Injection Rubber Molding Service?

Ensuring accurate and intricate part production

Meeting diverse industry needs

Proven track record in successful projects

Rigorous quality checks for reliable results

Professional Injection Molding One-Stop Service Company

FAQs of Custom Rubber Injection Molding

How Can Jiangzhi Help Me with Custom Injection Rubber Molding Solutions?

At Jiangzhi Rubber, we specialize in creating custom solutions to meet your specific needs. From helping you select the right materials to designing and optimizing molds, our experts will collaborate with you to ensure your parts meet the highest standards of quality, performance, and cost-effectiveness. Whether you’re looking for a small prototype or large-scale production, we’re here to bring your vision to life.

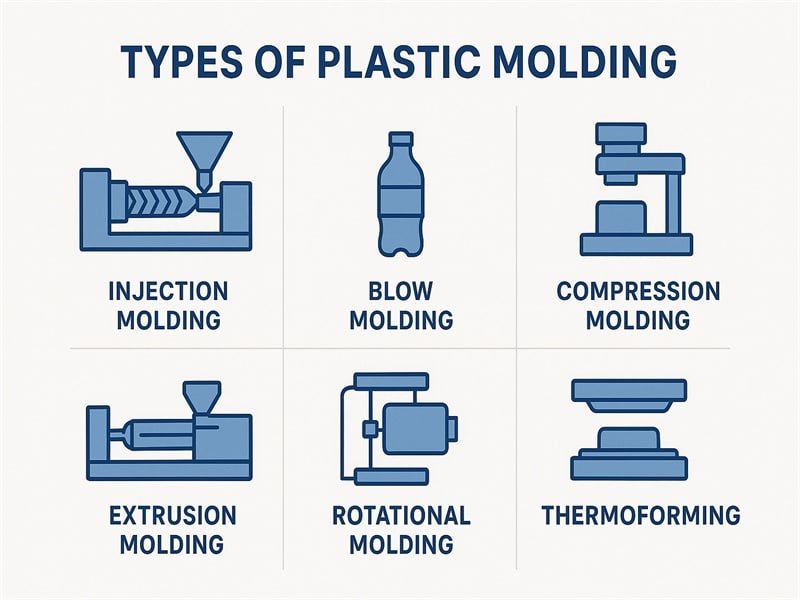

How is Injection Molding Rubber Different from Traditional Plastic Injection Molding?

How Do You Choose the Right Rubber Material for Injection Molding?

Choosing the right material depends on what you need the final part to do! Consider factors like flexibility, heat resistance, chemical exposure, and budget. Your material choice will ultimately impact the part’s performance in its intended application.

What Are Common Issues in Injection Molding Rubber and How Do You Fix Them?

Common Problems: Air bubbles, surface imperfections, mold blockages.

Solutions: Adjusting process parameters, tweaking material formulations, and conducting regular mold cleanings can help keep things running smoothly.

Tell me your confusion and let me solve it for you~

What Are the Benefits of EPDM Rubber Injection Molding?

Precision & Consistency: EPDM injection molding allows for high precision, producing parts with excellent dimensional accuracy and uniformity.

Cost-Effective: With automated processes, EPDM rubber injection molding can reduce labor costs and improve production efficiency—great for large-scale manufacturing.

Customizable: EPDM can be formulated to meet specific performance requirements, including varying hardness, chemical resistance, and color.

How hot doe silicon rubber need to be heated to be injected molded?

Can you injection mold EPDM?

Yes, we can injection mold EPDM (Ethylene Propylene Diene Monomer). EPDM is a versatile elastomer known for its excellent resistance to heat, ozone, weathering, and chemicals, making it an ideal material for a wide range of applications. Our advanced rubber injection molding process ensures that EPDM components are molded with high precision and durability, whether for automotive seals, industrial gaskets, or other custom parts. We can provide tailored solutions based on your specific design and performance requirements.