Contract Manufacturer for Heavy Equipment

Why Do Heavy Equipment Companies Use Jiangzhi

Supply Chain Flexibility

ISO Certified

Strong Production Capacity

Range of Service

Skilled and Experienced

What Materials Work Best for Heavy Equipment Parts

Nylon (Polyamide):

Excellent durability, chemical resistance, and low friction, suitable for gears and bearings.

Acetal (Polyoxymethylene, POM):

High strength, stiffness, and dimensional stability, ideal for precision parts and gears.

Polyethylene (PE):

Lightweight, chemical resistance, and impact strength, are used for various components.

Polypropylene (PP):

Resistant to chemical solvents, acids, and bases, commonly used for tanks and containers.

Polycarbonate (PC):

High impact strength, optical clarity, and heat resistance, suitable for transparent guards.

Nitrile Rubber (NBR):

Excellent oil and fuel resistance, commonly used for seals and gaskets.

EPDM (Ethylene Propylene Diene Monomer):

UV and ozone resistance, suitable for outdoor applications and gaskets.

Silicone Rubber:

Wide temperature range, flexibility, and biocompatibility, Silicone rubber is used in various industrial seals.

Neoprene (CR):

Reason: Good balance of oil resistance, weather resistance, and durability, used in industrial belts and gaskets.

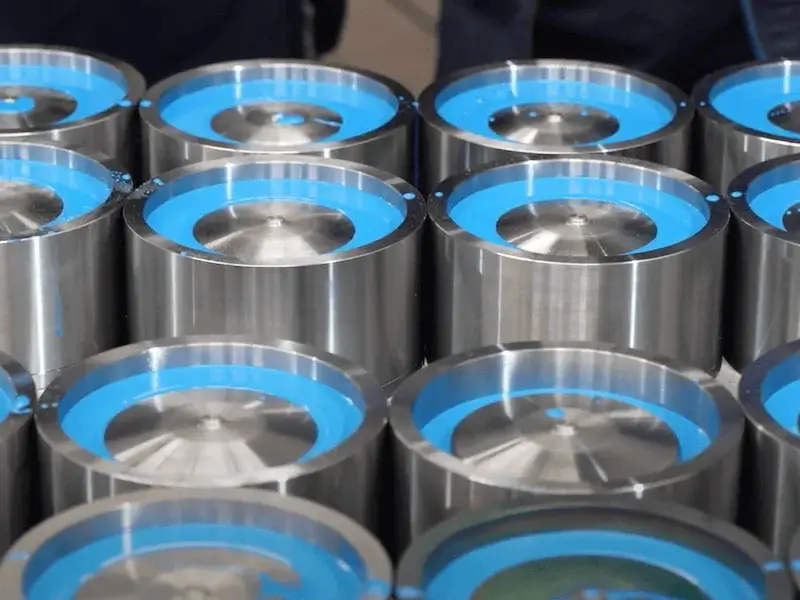

Heavy Equipment Parts Processing Service

Trusted by Leading Heavy Equipment Companies

Navigating Heavy Equipment Manufacturing Challenges with Precision

- Original Equipment Manufacturers (OEMs)

- Industrial Automation Providers

- Component Manufacturers

- Maintenance and Repair Operations

- Facility Managers

Common Heavy Equipment Parts

Discover a comprehensive range of rubber and plastic components meticulously engineered for peak performance in industrial heavy equipment.

- Plastic Gears and Bushings

- ABS Enclosures and Housings

- PVC Pipes and Tubing

- Polyurethane Conveyor Belts

- NBR Seals and Gaskets

- Vibration Isolators

- Nylon Rollers

- PU Urethane Wheels

- Cable and Wire Insulation

Contract Manufacturing Solution

Mold & Tooling Service

Design for Manufacturability

Surface Finishing