Understanding the CNC machining benefits is essential for businesses to enhance production processes, reduce costs, and stay competitive in today’s market. In this post, we will explore the key advantages of CNC machining, and learn why CNC machining has become an indispensable tool in modern manufacturing.

CNC (Computer Numerical Control) machining is a revolutionary technology for manufacturing. By automating control of machining tools via computers, CNC machining offers numerous advantages over traditional manual methods. In the following sections, we will explore the top CNC machining benefits and advantages compared to other manufacturing processes.

1. High Precision and Improved Accuracy

One of the foremost CNC machining benefits is its unparalleled precision and accuracy. Traditional manual machining often results in variations due to human error, but CNC machines operate with exceptional precision.

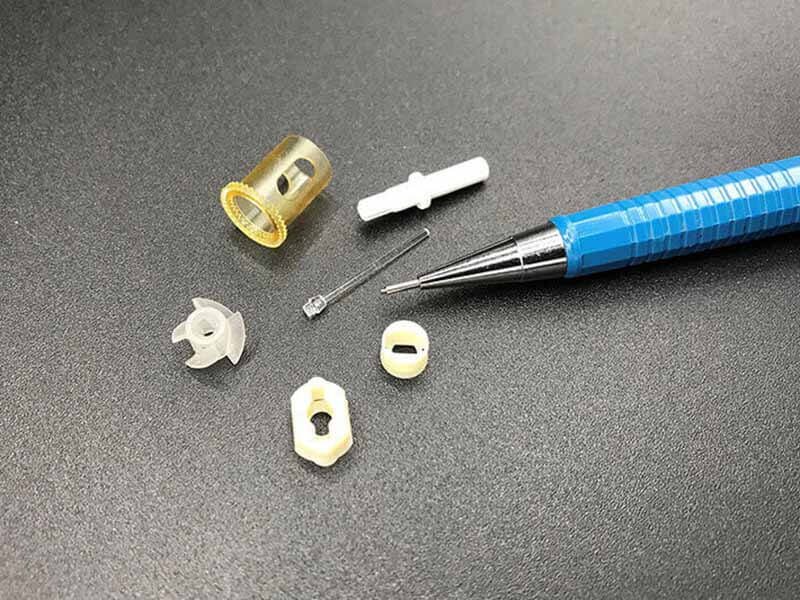

Tight Tolerances: CNC machines can achieve extremely tight tolerances, often up to ±0.001 inches. This level of precision is crucial for applications requiring exact specifications, such as aerospace components and medical devices.

Consistent Output: The digital nature of CNC machining ensures that once a program is created, the machine can replicate the same part multiple times with identical precision, reducing the likelihood of errors.

Advanced Software: CNC machines use advanced software for programming complex operations, ensuring high accuracy. CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software allow for precise design and machining instructions, further enhancing accuracy.

2. CNC Machining Improve Consistency and Repeatability

Consistency is vital in manufacturing, especially for large production runs. CNC machining excels in this regard, offering high repeatability.

Reliable Production: Once a CNC machine is programmed, it can produce hundreds or thousands of identical parts, each meeting the exact specifications. This consistency is essential for maintaining quality standards.

Quality Control: With CNC machining, quality control becomes more manageable as each part produced adheres to the programmed specifications, reducing the risk of defective parts.

Standardization: The ability to standardize production processes with CNC machining ensures uniformity across products, which is crucial for industries where consistency is key, such as automotive manufacturing.

3. High Efficiency and Speed

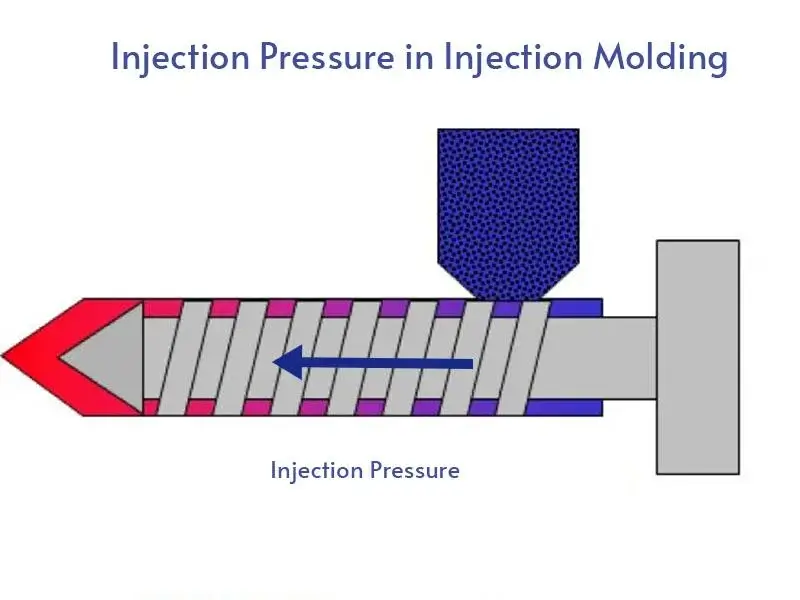

One of the standout CNC machining benefits is the ability to operate continuously with minimal supervision. Unlike manual machining, CNC machines can run 24/7, only pausing for maintenance or tool changes. This continuous operation maximizes production time and significantly boosts output, making CNC machining a highly efficient manufacturing process.

Continuous Operation: CNC machines can operate around the clock with minimal supervision. This continuous operation maximizes productivity and reduces production times.

Fast Production: CNC machines can perform complex operations more quickly than manual methods, leading to faster turnaround times for production runs.

Multi-Axis Capabilities: Modern CNC machines often have multi-axis capabilities, allowing them to perform several operations simultaneously. This capability speeds up the manufacturing process and reduces the need for multiple machines.

4. Lower Labor Costs

While the initial investment in CNC machinery can be high, the long-term reduction in labor costs is a significant CNC machining benefit.

Automation: CNC machines automate many tasks that would otherwise require manual labor, reducing the number of operators needed.

Labor Efficiency: With fewer operators needed to monitor and manage the machines, labor costs decrease, and those workers can be reassigned to more strategic roles within the company.

Skilled Labor Shortage: In industries facing a shortage of skilled labor, CNC machining reduces dependency on highly skilled machinists, as the machines perform most of the tasks once programmed.

5. Wide Range of Materials and Multiple Processes

Another of CNC machining benefit is its versatility. It can handle a wide range of materials and functions, making it suitable for various industries.

Material Compatibility: CNC machines can work with metals (such as aluminum, steel, and titanium), plastics, composites, and even wood. This versatility makes CNC machining applicable to numerous fields.

Complex Geometries: CNC machining can create complex shapes and intricate designs that would be challenging or impossible to achieve with manual methods. This capability is essential for custom projects and innovative designs.

Multiple Processes: CNC machines can perform various processes such as CNC drilling, CNC milling, CNC turning, and CNC grinding, all within the same setup, increasing efficiency and reducing setup times.

6. Minimize Material Wastage

Efficient material usage is a critical aspect of cost-effective manufacturing, and CNC machining excels in minimizing waste.

Precision Cutting: CNC machines are programmed to optimize material usage, ensuring that cuts are made precisely where needed. This precision reduces the amount of excess material and scrap.

Cost Savings: By minimizing waste, CNC machining lowers the cost of raw materials, contributing to overall cost efficiency in the manufacturing process.

Sustainability: Reducing material waste not only saves costs but also supports sustainability efforts by minimizing the environmental impact of manufacturing processes.

7. Improved Operator Safety

Safety is a paramount concern in any manufacturing environment, and CNC machining significantly enhances workplace safety.

Operator Safety: CNC machines reduce the need for operators to be in close contact with cutting tools and materials, thereby reducing the risk of accidents.

Error Reduction: Automated processes diminish the chances of human error, which is often a significant factor in workplace accidents. This reduction leads to a safer work environment.

Enclosed Workspaces: Many CNC machines have enclosed workspaces that contain any flying debris or coolant, further protecting operators from potential hazards.

8. Ideal Solution for Prototyping

Prototyping is a crucial phase in product development, and CNC machining offers significant advantages in this area.

Rapid Prototyping: CNC machines can quickly produce prototypes from digital designs, allowing for rapid iteration and refinement of products.

Cost-Effective Development: The ability to produce prototypes quickly and accurately reduces the time and cost associated with product development, enabling faster time-to-market.

Design Flexibility: Changes to the prototype design can be easily made in the software and quickly implemented, allowing for flexible and dynamic development processes.

9. Fewer Human Error

Human error is a common issue in manual machining, leading to inconsistencies and defects. CNC machining dramatically reduces the incidence of such errors.

Automated Precision: The automation of CNC machines ensures that every operation is performed with exacting precision, adhering to the programmed specifications without deviation.

Consistent Quality: By minimizing human intervention, CNC machining consistently produces high-quality parts, reducing the likelihood of defects and rework.

Advanced Monitoring: CNC machines often include monitoring systems that track performance and detect potential issues in real time, allowing for immediate corrections and further reducing errors.

10. Greater Flexible

Flexible is another critical CNC machining benefits, making it suitable for both small and large production runs.

Adaptable Production: CNC machines can easily switch from producing one part to another by simply reprogramming the machine. This flexibility allows manufacturers to scale production up or down based on demand.

Efficient Setup: Quick changeover times and the ability to handle diverse projects without extensive retooling mean that CNC machining is ideal for both custom and mass production scenarios.

Bulk Production: CNC machining can efficiently handle bulk production, maintaining the same level of precision and quality across large quantities, making it ideal for industries with high-volume requirements.

Conclusion of CNC Machining Benefits

The benefits of CNC machining are clear and compelling. From increased precision and accuracy to improved safety and reduced labor costs, CNC machining offers a wide array of advantages. Its versatility, efficiency, and ability to minimize waste and human error underscore its value across various industries. Whether you’re looking to produce a single prototype or embark on large-scale production, CNC machining provides the reliability and quality needed to meet the demands of today’s competitive markets. By leveraging the myriad CNC machining benefits, manufacturers can stay ahead of the competition, deliver superior products, and ensure long-term growth and sustainability in their operations.