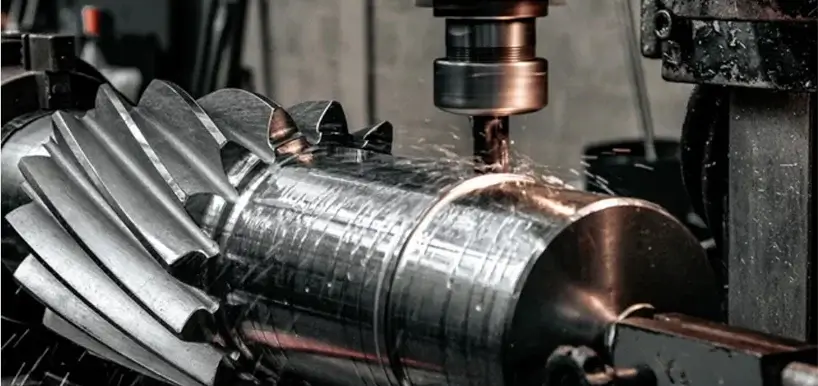

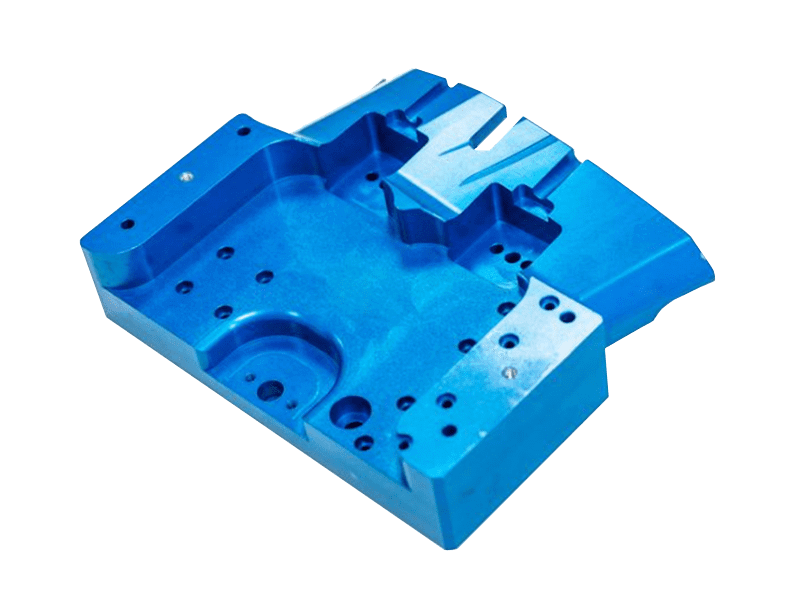

CNC Machining Service

High-level post-processing effects, to meet the material, appearance, structural requirements

- Supports processing of various engineering plastics and metals

- Multi-axis machining services

CNC Machining Process

CNC Milling

CNC Turning

CNC Machining Materials

Plastic Material

- ABS

- POM

- HDPE

- LDPE

- Nylon

- PMMA

- Polycarbonate

- Polypropylene

- PTFE

Metal Material

- Aluminum

- Brass

- Copper

- Stainless Steel

- Steel Alloy

- Steel Mild Low Carbon

CNC Machining Surface Finishing

| Finish | Description |

|---|---|

| Anodizing | Corrosion-resistant ceramic additions are added to the surface of machined parts, which can be dyed in different colors, most commonly clear, black, red and gold. |

| Sandblasting | Sandblasting is the process of adding a uniform matte or satin surface finish to machined parts, removing tool marks, primarily for visual purposes |

| Powder Coating | This is a process in which powder coatings are sprayed onto parts and then baked in an oven to create a strong, abrasion- and corrosion-resistant surface, and is available in a wide range of colors. |

| Electroplating | A process that utilizes an electric current to reduce dissolved metal cations so that they form a thin metallic layer on the motor. Helps to place corrosion and improve wear resistance, electrical conductivity, reflectivity and aesthetics |

| Polishing | |

| Brushing | Brush coating can be used for a variety of purposes on plastic parts, such as cleaning, edge blending and deburring. It is the best way to protect the surface from damage and scratches. |

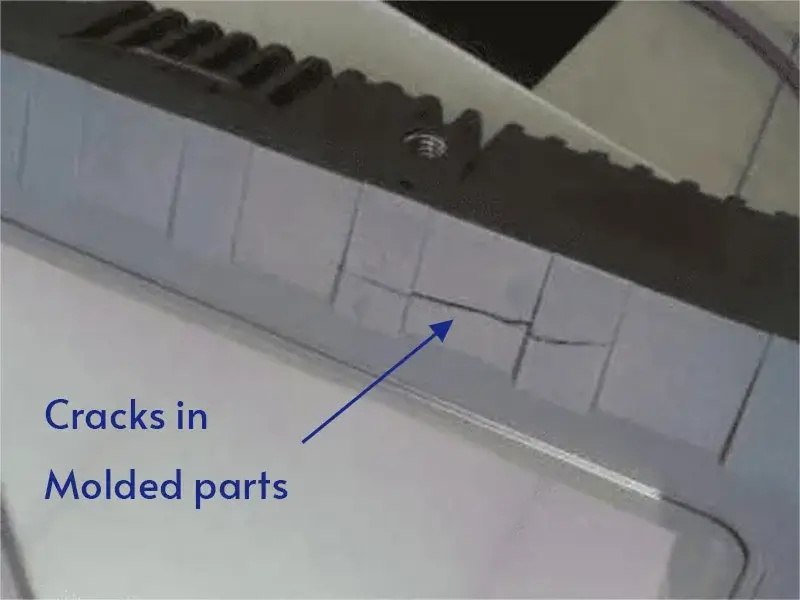

Understanding and Preventing Cracks in Molded Parts

Advantages of CNC Machining

Compared to manual machining, CNC technology improves efficiency and accuracy, resulting in faster production, safer operations and lower costs.

- CNC machining have little to no waste of material

- High precision and greater accuracy

- Faster and efficient production

- Less dependabilitiy on human labor and fewer human errors

- Reduction in energy consumption

CNC Machining Application

CNC machining is an advanced manufacturing process that can create many different products that used in a variety of industries, making it very useful in modern manufacturing. Commonly manufactured parts include:

- Gears

- Shafts

- Brackets

- Housings

- Pistons

- Fasteners

- Valves

- Connectors

- Fittings

- Bushings

Why Choose Us

Ensuring accurate and intricate part production

Meeting diverse industry needs

Proven track record in successful projects

Rigorous quality checks for reliable results

Contract Manufacturing Solution

Mold & Tooling Service

Design for Manufacturability

Surface Finishing

Assembly Manufacturing

FAQs of CNC Machining

How long does CNC machining take?

Generally, for 1-10 pieces, delivery takes around 3-5 days, and for 10-500 pieces, it takes 7-20 days.

How accurate is CNC machining?

CNC is a process with high precision, in general the accuracy of CNC machining is between 0.01mm to 0.03mm

How to make CNC parts cheaper?

There are several tips to make CNC parts cheaper, following are some the examples:

- Rounded internal corners

- Limit the use of tight tolerances for cheap CNC machining

- Use less expensive material in CNC milling machined parts

- Avoid multiple finishes

- Order larger quantities

- Avoid deep pockets

- Limit the length of threads