Custom Rubber Injection Molding Service

Jiangzhi offers custom rubber injection molding for both low-volume and end-use production. Typically, we use steel as the tooling material to ensure mold durability. Our mold costs start at only $500. Additionally, we provide a variety of elastomers, allowing you to choose the perfect material for your project.

Rubber Injection Molding Capabilities

| Name | Detail |

|---|---|

| Size |

78.74in. x 59.05in. x 39.37in. 2000mm x 1500mm x 1000mm |

| Mold Cavities | Single or multi-cavity |

| Mold Life | Unlimited (We will open a new mold if the old one worn out) |

| Mold Storage | Forever |

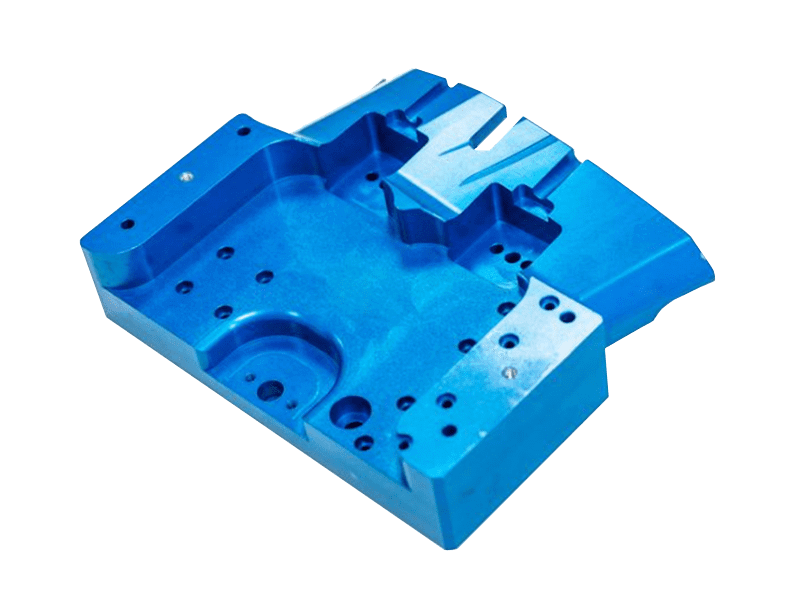

| Mold Material | P20 Steel |

| General Tolerance | Normally +/- 0.008in.(0.2mm) |

Rubber Injection Molding Material

Rubber Materials

- Silicone

- EPDM (Ethylene Propylene Diene Monomer)

- Nitrile (NBR)

- Neoprene (CR)

- SBR (Styrene Butadiene Rubber)

- Natural Rubber (NR)

- Butyl Rubber (IIR)

- Viton (FKM)

Additives

- Softeners

- Colorants

- UV Stabilizers

- Flame Retardants

- Lubricants

- Reinforcing Agents

Rubber Injection Molding Surface Finishing

| Finish | Description |

|---|---|

| SPI A1 | 6000 grit diamond, surper high glossy finish |

| SPI A2 | 3000 grit diamond, high glossy finish |

| SPI A3 | 1200 grit diamond, normal glossy finish |

| SPI B1 | 600 grit paper, fine semi-glossy finish |

| SPI B2 | 400 grit paper, normal semi-glossy finish |

| SPI B3 | 320 grit paper, normal semi- |

| SPI C1 | 600 grit stone, fine matte finish |

| SPI C2 | 400 grit stone, medium matte finish |

| SPI C3 | 320 grit stone, normal matte finish |

| SPI D1 | Dry blast glass bead, satin textured finish |

| SPI D2 | Dry blast, dull textured finish |

| SPI D3 | Dry blast, rough textured finish |

How Does Rubber Injection Molding Work

Material Preparation

Injection Molding

Curing or Vulcanization

Demolding

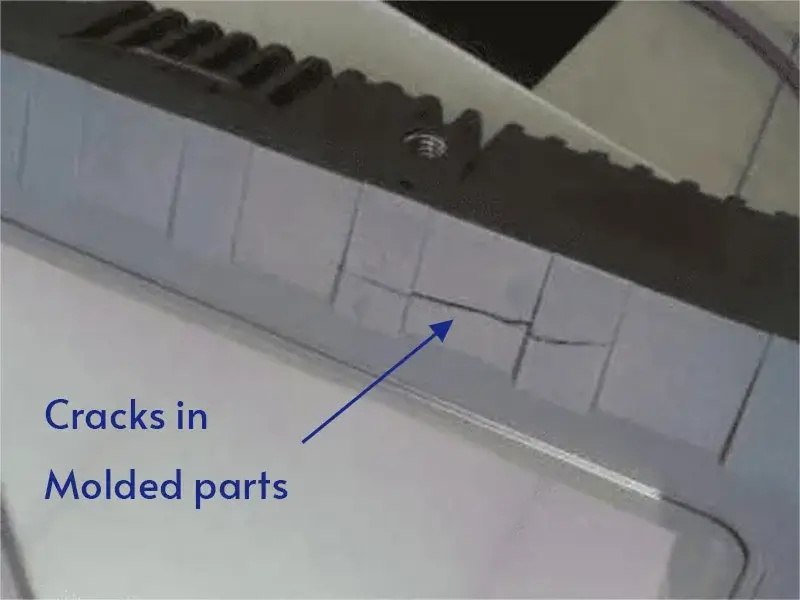

Key Rubber Parts Defects You Need To Know

Why Choose Us

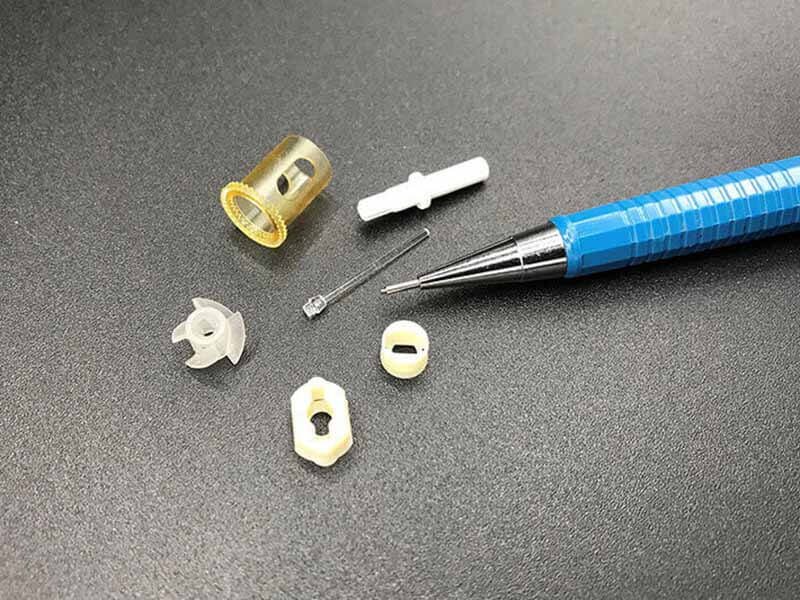

Ensuring accurate and intricate part production

Meeting diverse industry needs

Proven track record in successful projects

Rigorous quality checks for reliable results

Contract Manufacturing Solution

Mold & Tooling Service

Design for Manufacturability

Surface Finishing

Assembly Manufacturing

FAQs of Rubber Injection Molding

How long is the rubber injection molding cycle?

The whole injection moulding process usual lasts from 2 seconds to 2 minutes. There are four stages in the cycle. These stages are the clamping, injection, cooling and ejection stages.

What is the temperature for rubber injection molding?

While thermoplastics are usually injected around the melt temperature of the polymer to obtain the required flow of the material through a hot runner system, rubber compounds only admit temperatures between 70-110℃.

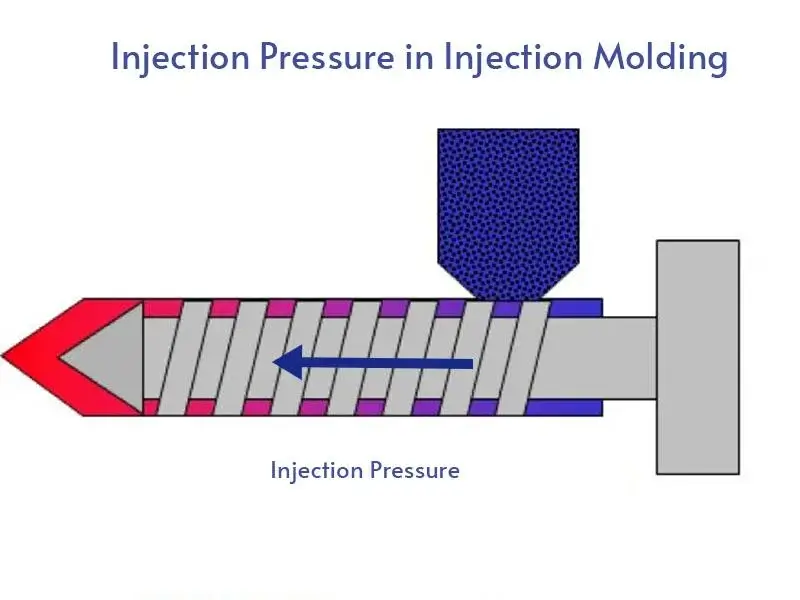

What is the pressure for rubber injection molding?

The pressure for rubber injection molding is approximately 150 to 220 bar, but it can be considered negligible because the mixing has not yet occurred.

What is the difference between rubber and plastic injection molding?

Rubber is more difficult to inject into an injection mold cavity compared to plastic materials like ABS, PC, or PPS due to the differences in their physical and chemical properties.